Steel, carburized steel component, and carburized steel component production method

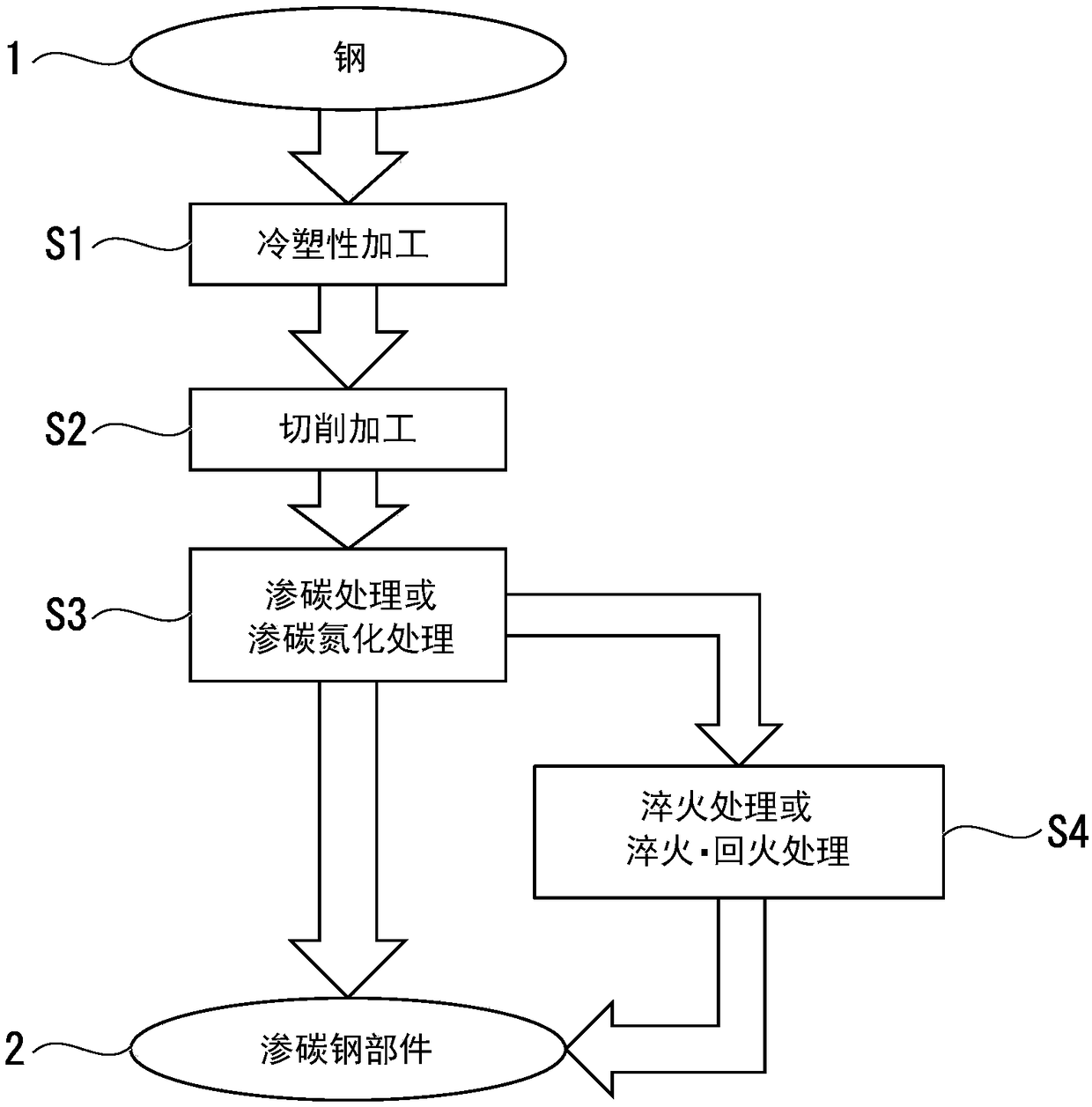

一种渗碳钢、部件的技术,应用在制造工具、涂层、炉子类型等方向,能够解决冷锻性降低等问题,达到切削性优异、廉价制造、冷锻性优异的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0172] Steels a to aa having the chemical compositions shown in Table 1A and Table 1B were melted in a 270-ton converter, and continuously casted using a continuous casting machine to manufacture a 220×220 mm square billet. Here, the superheat of the molten steel in the tundish was set to 30° C., and the casting speed was set to 1.0 m / min.

[0173] In the continuous casting of the slab, the average cooling rate in the temperature range from the liquidus temperature to the solidus temperature at a depth of 15 mm from the surface of the slab was determined by changing the amount of cooling water in the mold. control. In this manner, continuous casting was performed on slabs a to aa having the chemical compositions shown in Table 1A and Table 1B and having dendrite primary arm intervals of less than 600 μm within a range of 15 mm from the surface.

[0174] Steels a to o shown in Table 1A and Table 1B are steels having chemical compositions defined in the present invention. Stee...

Embodiment 2

[0226] Except for the average cooling rate (hereinafter referred to as "average cooling rate") in the temperature range from the liquidus temperature to the solidus temperature at a position at a depth of 15 mm from the surface of the slab, it is the same as steel a and steel Under the same manufacturing conditions as h, carburizing steels having the same chemical composition as steel a or steel h were produced, and various evaluations were performed on these carburizing steels by the same methods as steel a and steel h. The average cooling rate was set to the value shown in Table 3.

[0227] [table 3]

[0228]

[0229] As shown in Table 3, in Test Nos. 1 and 8 in which the average cooling rate was in the range of 100 to 500°C, since the sulfide was finely dispersed properly, the hardness before carburization, ultimate compressibility, The amount of wear on the flank surface and the weight of chips are within the acceptable range, and the thickness of the carburized layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com