Silicon carbide power device having step structure and fabrication method of silicon carbide power device

A power device, silicon carbide technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of N-type SiC surface doping characteristics change, affecting low device turn-on voltage, restricting industrialization development, etc. Achieve the effect of improving electric field concentration, high breakdown voltage, and reducing the need for complex high-temperature processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

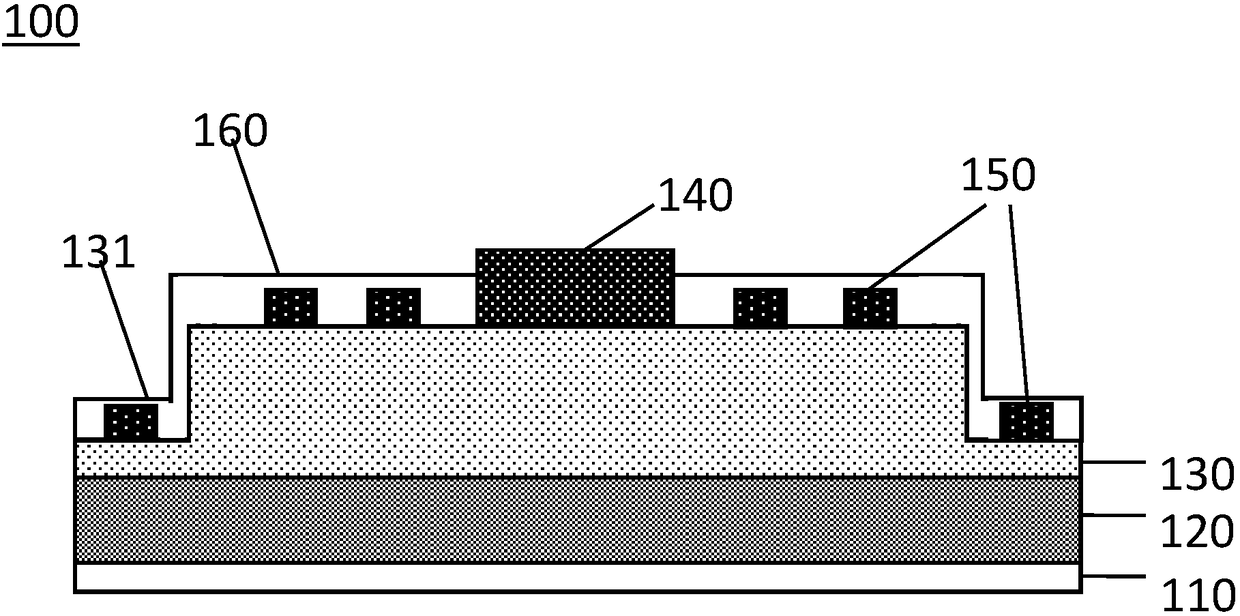

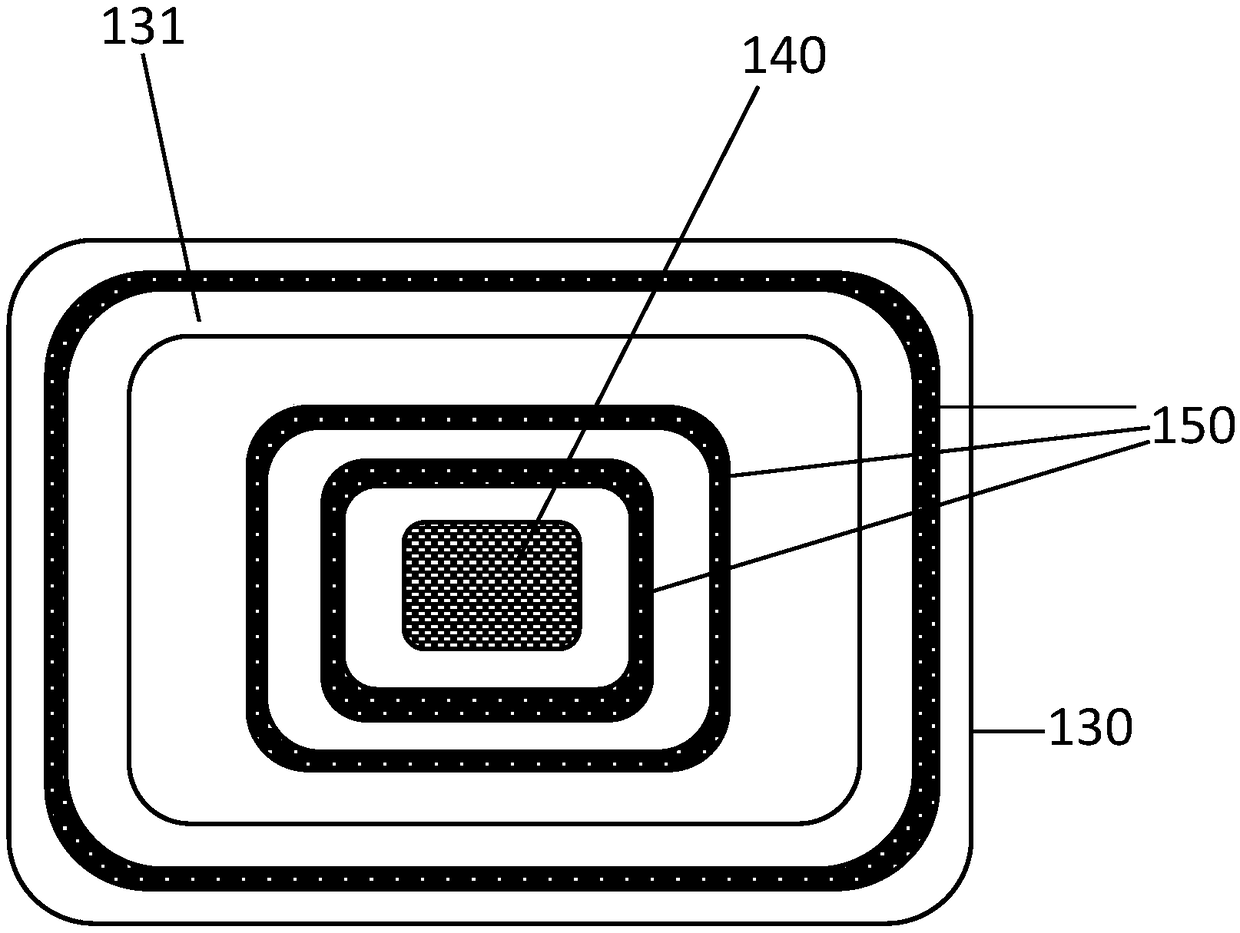

[0036] refer to figure 1 and figure 2 , a silicon carbide Schottky barrier diode (SBD) 100, comprising an ohmic contact electrode 110, N + SiC substrate layer 120, N - SiC epitaxial layer 130, Schottky contact electrode 140, P-type junction terminal 150 and passivation layer 160, ohmic contact electrode 110, N + SiC substrate layer 120 and N - The SiC epitaxial layer 130 is stacked sequentially from bottom to top, and the Schottky contact electrode 140 and the P-type junction terminal 150 are arranged on the N - On the upper surface of the SiC epitaxial layer 130, the Schottky contact electrode 140 is located in the center, and the P-type junction terminal 150 is a closed ring structure and is arranged around the periphery of the Schottky contact electrode 140 in turn. The P-type junction terminal 150 and the N - The SiC epitaxial layer 130 forms a PN heterojunction, and the passivation layer 160 covers the exposed N - SiC epitaxial layer 130 and P-type junction terminat...

Embodiment 2

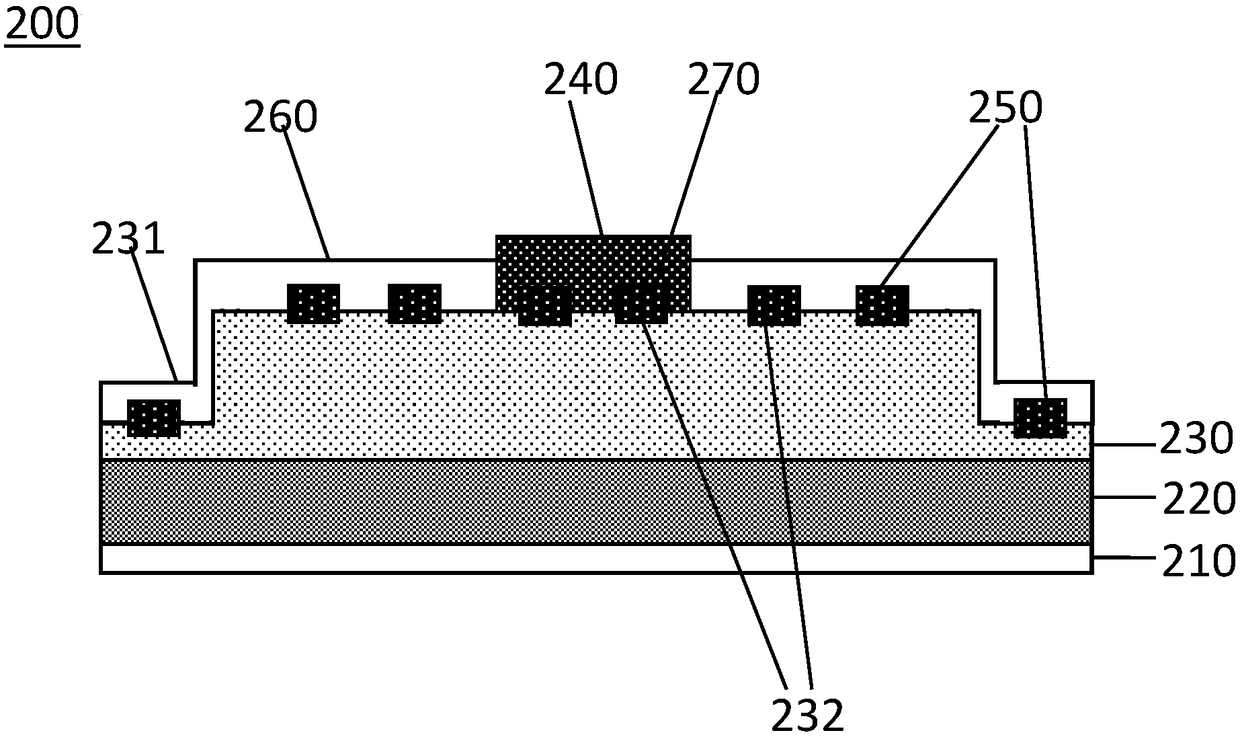

[0049] refer to image 3 , a silicon carbide junction barrier Schottky diode (JBS) 200, comprising an ohmic contact electrode 210, N + SiC substrate layer 220, N - SiC epitaxial layer 230 , Schottky contact electrode 240 , P-type junction termination 250 , passivation layer 260 and P-type structure 270 . Ohmic contact electrodes 210, N + SiC substrate layer 220 and N - The SiC epitaxial layer 230 is stacked sequentially from bottom to top, and the Schottky contact electrode 240, the P-type junction terminal 250 and the P-type structure 270 are arranged on the N - On the upper surface of the SiC epitaxial layer 230, the Schottky contact electrode 240 is located in the center, and the P-type junction terminal 250 is a closed ring structure and is arranged around the Schottky contact electrode 240 in turn. Similarly, N - The edge of the surface of the SiC epitaxial layer 230 is provided with an annular step 231, and the P-type junction terminal 250 is distributed on the upper...

Embodiment 3

[0054] refer to Figure 4 , a silicon carbide power device is a silicon carbide PN junction diode 300, including ohmic contact electrodes 310, N + SiC substrate layer 320, N - SiC epitaxial layer 330 , Schottky contact electrode 340 , P-type junction terminal 350 , passivation layer 360 and P-type layer 370 . The difference from Embodiment 2 is that the P-type layer 370 is a whole-layer structure, which is arranged between the Schottky contact electrode 340 and the N - Between the SiC epitaxial layer 330 and isolating the Schottky contact electrode 340 and the N - SiC epitaxial layer 330, P-type layer 370 and N - A PN junction is formed between the SiC epitaxial layers 330 . Likewise, N - The SiC epitaxial layer 330 is provided with an annular step 331 and a groove 332, and the P-type junction terminal 350 and the P-type layer 370 are formed in the groove 332 in one-to-one correspondence, and the P-type junction terminal 350 is distributed at the level of the annular step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com