Whole water-repellent natural fiber spunlace non-woven fabric and production equipment thereof

A spunlace non-woven fabric and natural fiber technology, applied in the field of weaving, can solve problems affecting comfort, reverse osmosis, menstrual blood residual sanitary napkins, etc., and achieve the effect of avoiding reverse osmosis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

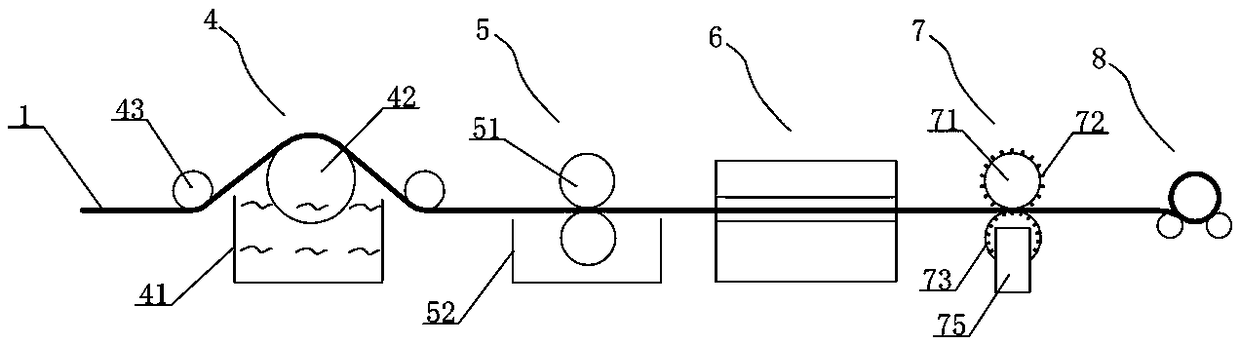

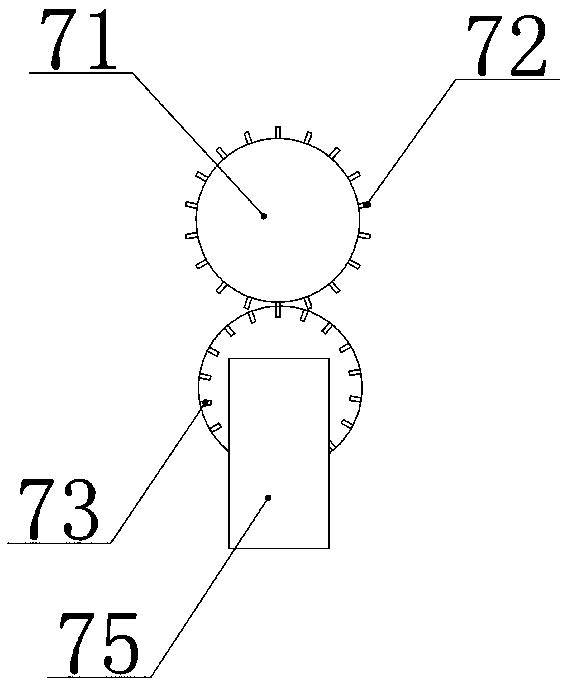

[0018] The present invention will be further elaborated below by means of the accompanying drawings and examples.

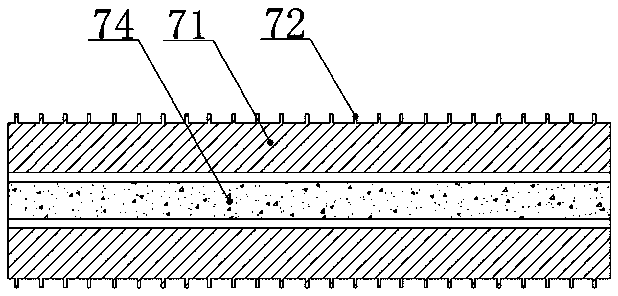

[0019] Such as Figure 4 Shown: a fully water-repellent natural fiber spunlace non-woven fabric, including natural fiber spunlace non-woven fabric 1, one surface of natural fiber spunlace non-woven fabric 1 is coated with a water-repellent layer 2, natural fiber spunlace non-woven fabric The cloth 1 and the water-repellent layer 2 are covered with holes 3 passing through both.

[0020] When the fully water-repellent natural fiber spunlace nonwoven fabric of the present invention is used, the water-repellent layer 2 is in contact with the skin. Since the surface of the natural fiber spunlace non-woven fabric 1 is coated with a water-repellent layer 2, the menstrual blood will not reverse seepage after being sucked into the natural fiber spunlace non-woven fabric 1 through the hole 3, so as to achieve the purpose of one-way absorption and avoid the Menstrual bloo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com