An operation method of a liquid slag flow control device with quick replacement and accident handling functions

A liquid slag and operation method technology, applied in the field of liquid slag flow control devices, can solve high-temperature corrosion and other problems, achieve the effects of deteriorating the operating environment, preventing splashing around, and preventing cooling and condensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

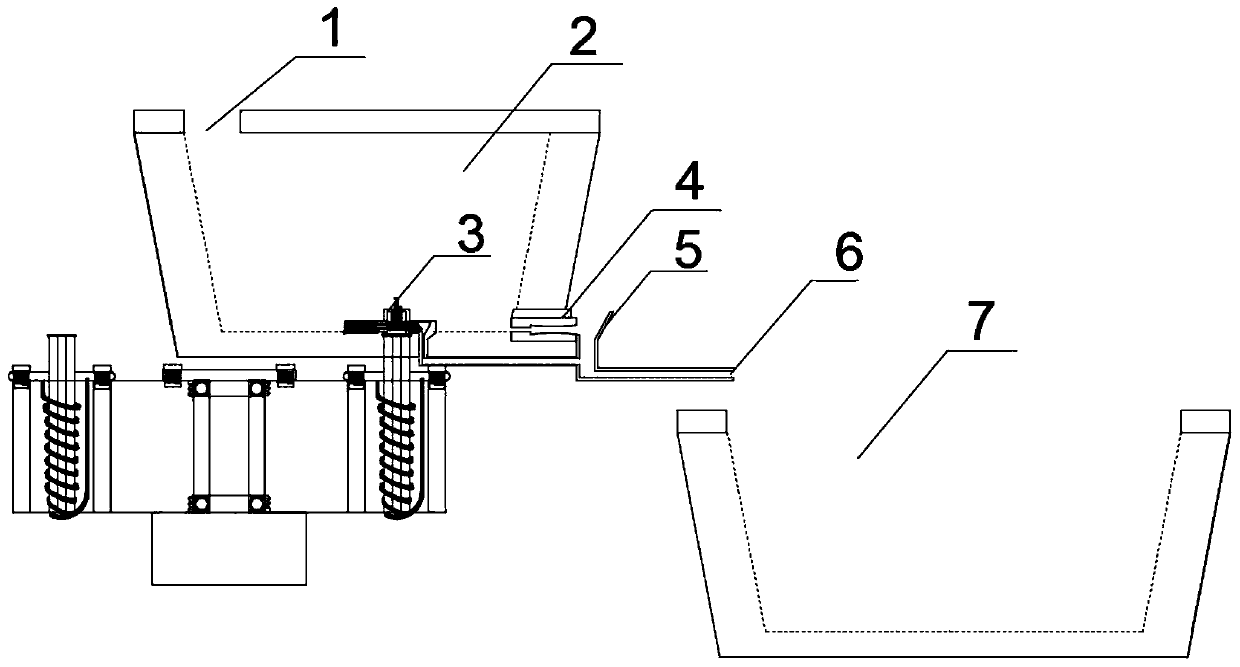

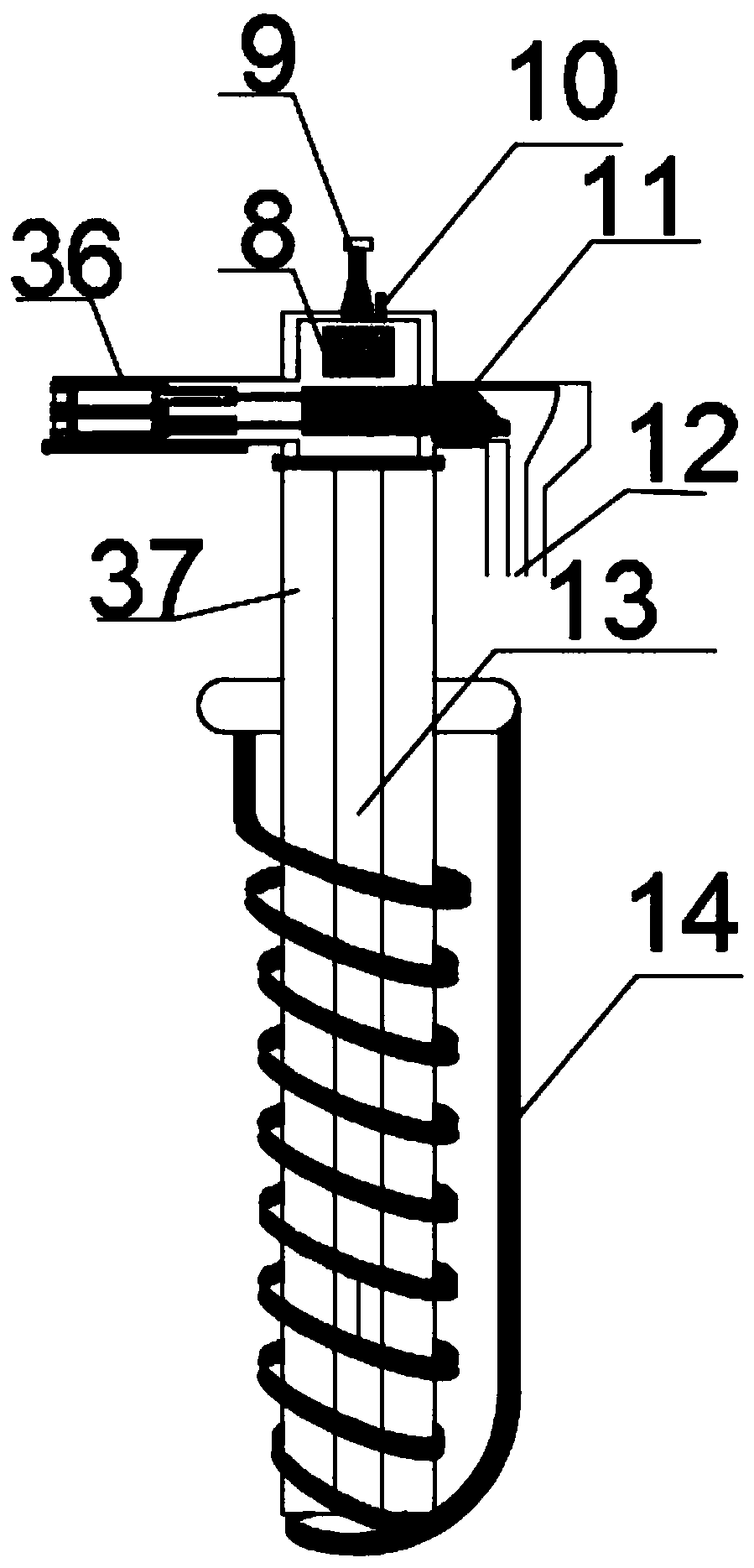

[0034] see Figure 1 to Figure 7 As shown, a liquid slag flow control device with quick replacement and accident handling functions, including a slag bag; a slag bag inner cavity 2 is provided inside the slag bag; a liquid slag inlet for liquid slag to flow in is provided on the upper part of the slag bag 1. A slag dropping device 3 with a turntable is installed at the bottom of the slag bag, and liquid slag can flow out through the slag dropping device 3 with a turntable and enter the subsequent processing unit. At the same time, the bottom side wall of the slag bag is provided with a slag bag accident slag discharge sizing nozzle 4 and a normal working sizing nozzle 19; The bottom of the slag discharge baffle 5 is provided with an accident slag collection outlet 6, and the liquid slag can enter the accident slag pit 7 at the bottom by the accident slag collection outlet 6, and is used to discharge the slag in the slag bag during an accident.

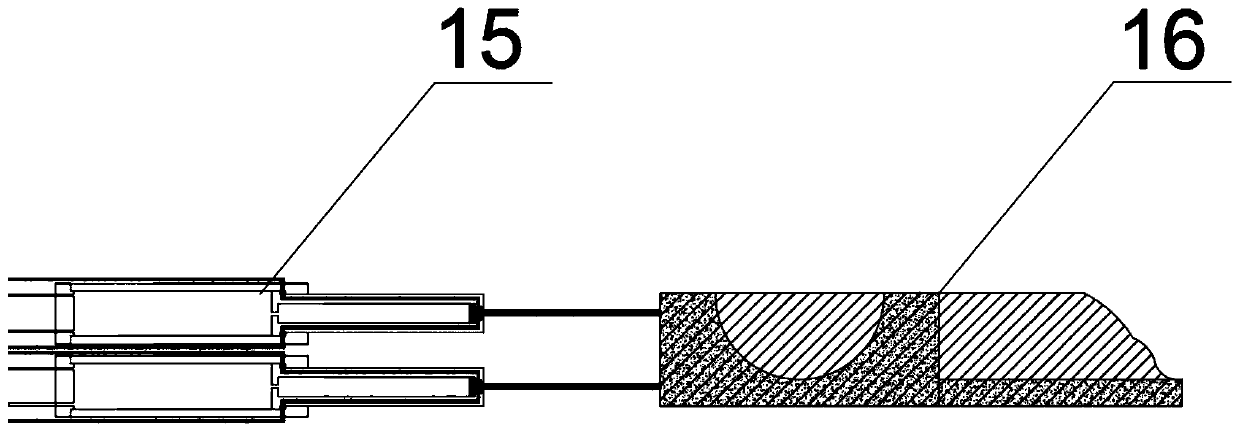

[0035] The outside of the sizi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com