Novel nanoalloy root-system-resistant composite coil and preparation method thereof

A nano-alloy and composite roll technology, applied in the direction of adhesive type, adhesive additive, asphalt material adhesive, etc., can solve the problem that the waterproof roll is easy to be corroded, affects the overall performance of the waterproof layer, and is resistant to tension and tearing Poor performance and other problems, to achieve the effects of good plant root dredging and growth, good water moisturizing and water retention functions, and strong root puncture resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

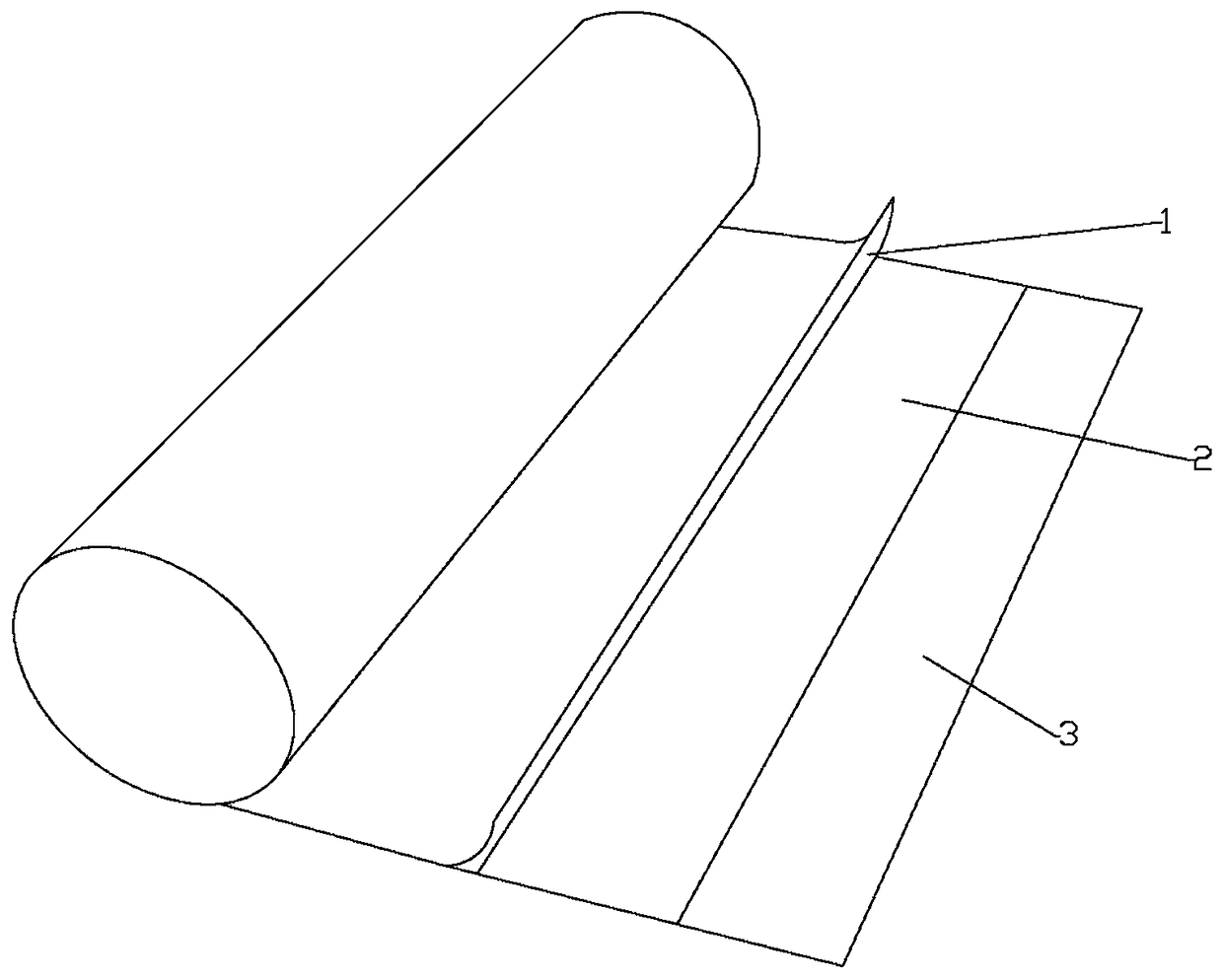

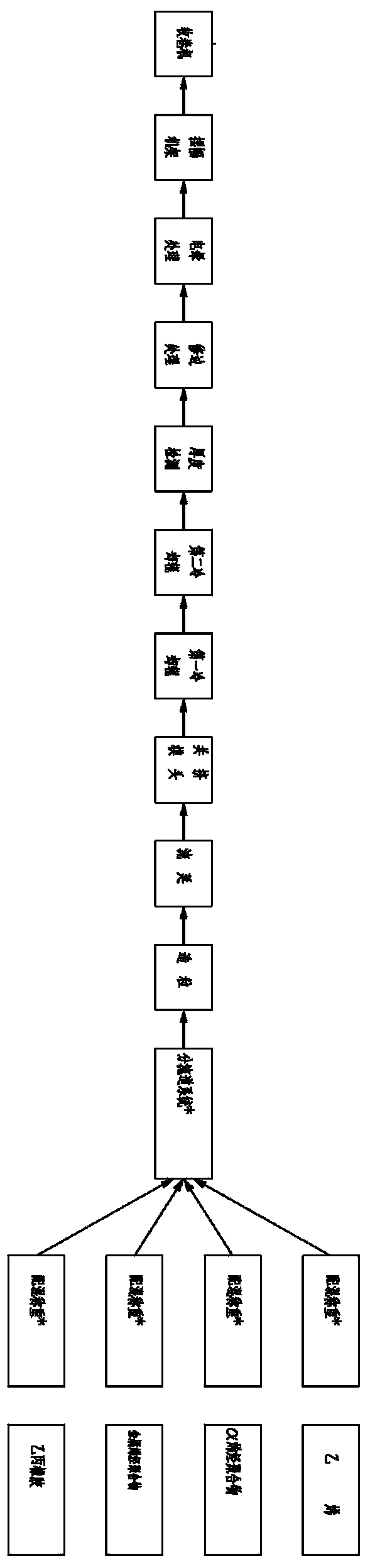

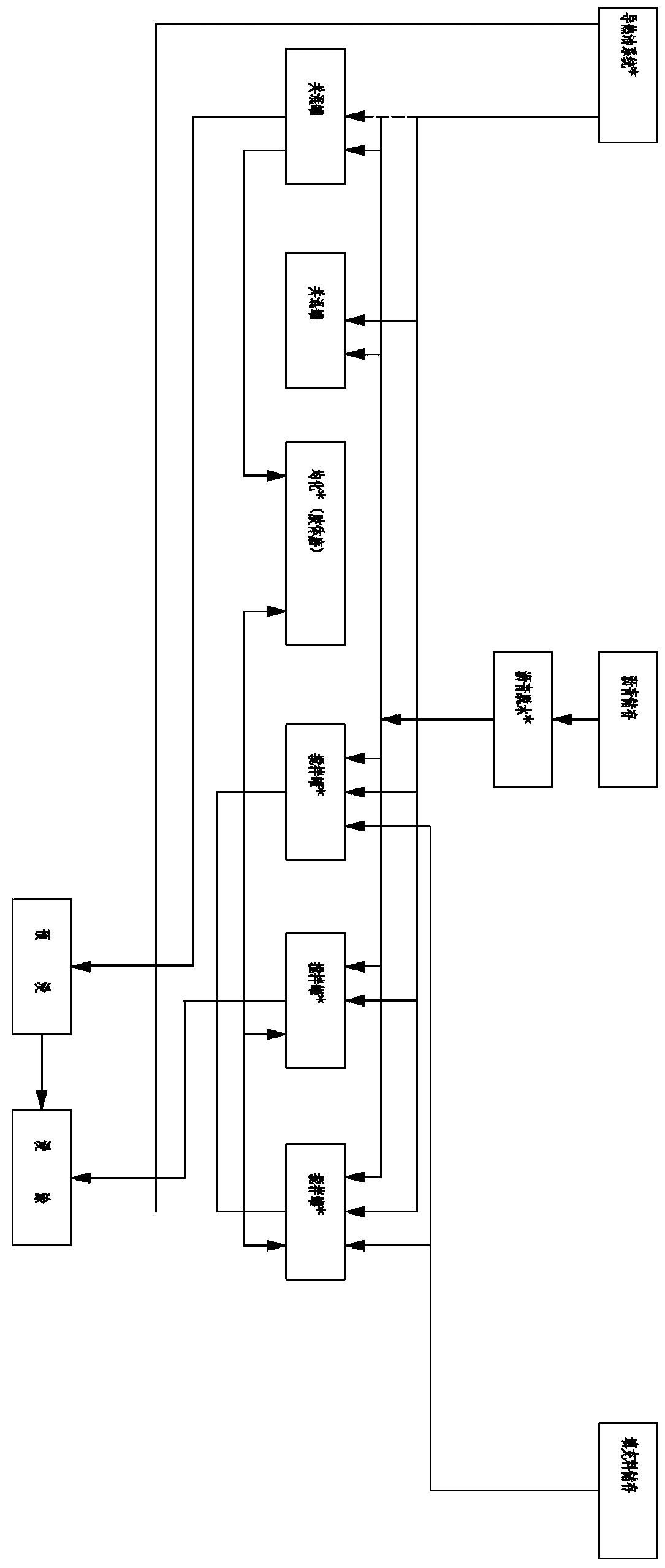

[0035] Embodiment 1: a kind of novel nano-alloy root-resistant composite coil, such as figure 1 As shown, including the coiled material, the coiled material is a composite nano-alloy heat insulation layer 1, an asphalt-based waterproof layer 2 and a cladding layer 3 from top to bottom; the composite nano-alloy heat-insulation layer 1 is the carcass, and the composite nano-alloy heat-insulation layer 1 is a polyolefin nano-alloy heat insulation layer, which is composed of ethylene, α-olefin polymer, metal olefin polymer and ethylene-propylene rubber; the composite nano-alloy heat insulation layer 1 and the asphalt-based waterproof layer 2 are heated Melt adhesive bonding. The asphalt-based waterproof layer 2 is composed of rubber polymer and asphalt base material, and the asphalt-based waterproof layer 2 is made by modifying asphalt base material and styrene-butadiene-styrene ternary block polymer. The undercoat surface of the asphalt-based waterproof layer 2 is provided with ...

Embodiment 2

[0049] Embodiment 2: as Figure 1-5 As shown, a new type of nano-alloy root-resistant composite coil, including the coil, the coil is composite nano-alloy insulation layer 1, asphalt-based waterproof layer 2 and cladding layer 3 from top to bottom; composite nano-alloy insulation layer 1 is the carcass, the composite nano-alloy insulation layer 1 is the polyolefin nano-alloy insulation layer, and the polyolefin nano-alloy insulation layer is composed of ethylene, α-olefin polymer, metal olefin polymer and ethylene-propylene rubber; the composite nano-alloy insulation layer The thermal layer 1 and the asphalt-based waterproof layer 2 are bonded by hot-melt adhesive. The asphalt-based waterproof layer 2 is composed of rubber polymer and asphalt base material, and the asphalt-based waterproof layer 2 is made by modifying asphalt base material and styrene-butadiene-styrene ternary block polymer. The undercoat surface of the asphalt-based waterproof layer 2 is provided with an ino...

Embodiment 3

[0063] Embodiment 3: as Figure 1-5 As shown, a new type of nano-alloy root-resistant composite coil, including the coil, the coil is composite nano-alloy insulation layer 1, asphalt-based waterproof layer 2 and cladding layer 3 from top to bottom; composite nano-alloy insulation layer 1 is the carcass, the composite nano-alloy insulation layer 1 is the polyolefin nano-alloy insulation layer, and the polyolefin nano-alloy insulation layer is composed of ethylene, α-olefin polymer, metal olefin polymer and ethylene-propylene rubber; the composite nano-alloy insulation layer The thermal layer 1 and the asphalt-based waterproof layer 2 are bonded by hot-melt adhesive. The asphalt-based waterproof layer 2 is composed of rubber polymer and asphalt base material, and the asphalt-based waterproof layer 2 is made by modifying asphalt base material and styrene-butadiene-styrene ternary block polymer. The undercoat surface of the asphalt-based waterproof layer 2 is provided with an ino...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com