Degradable cable tie material and preparation method thereof

A technology of belt material and alcoholysis degree, applied in the field of cable tie material and its preparation, degradable cable tie material and its preparation, can solve the problems of affecting the scope of application of the cable tie, reducing biocompatibility, difficult to control the degradation cycle, etc. Achieve the effect of easy industrialization, good biocompatibility, and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with embodiment the present invention is described in further detail.

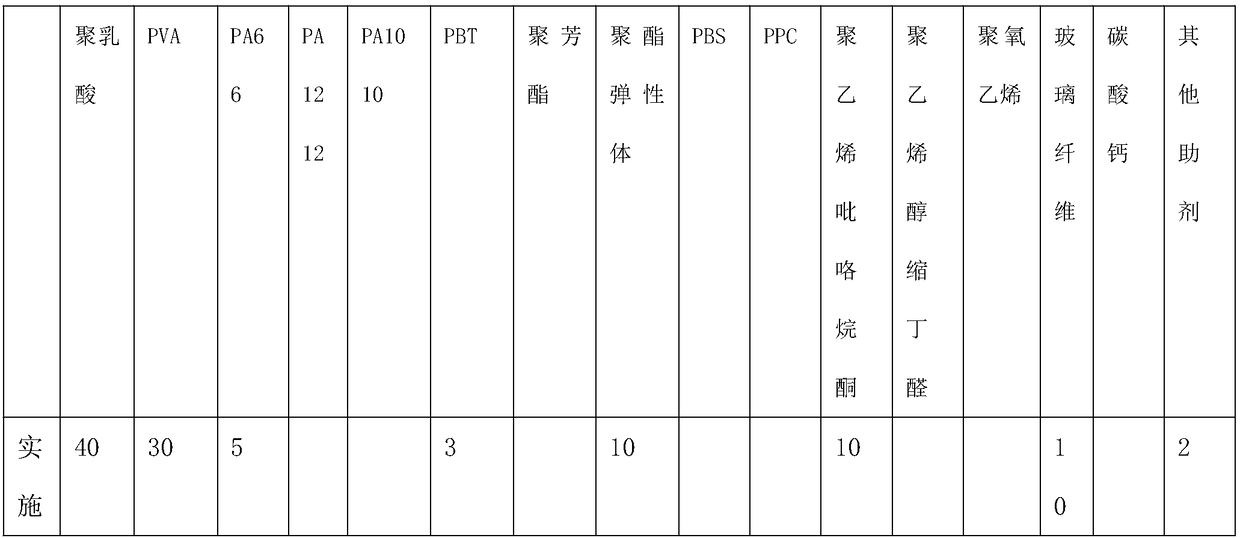

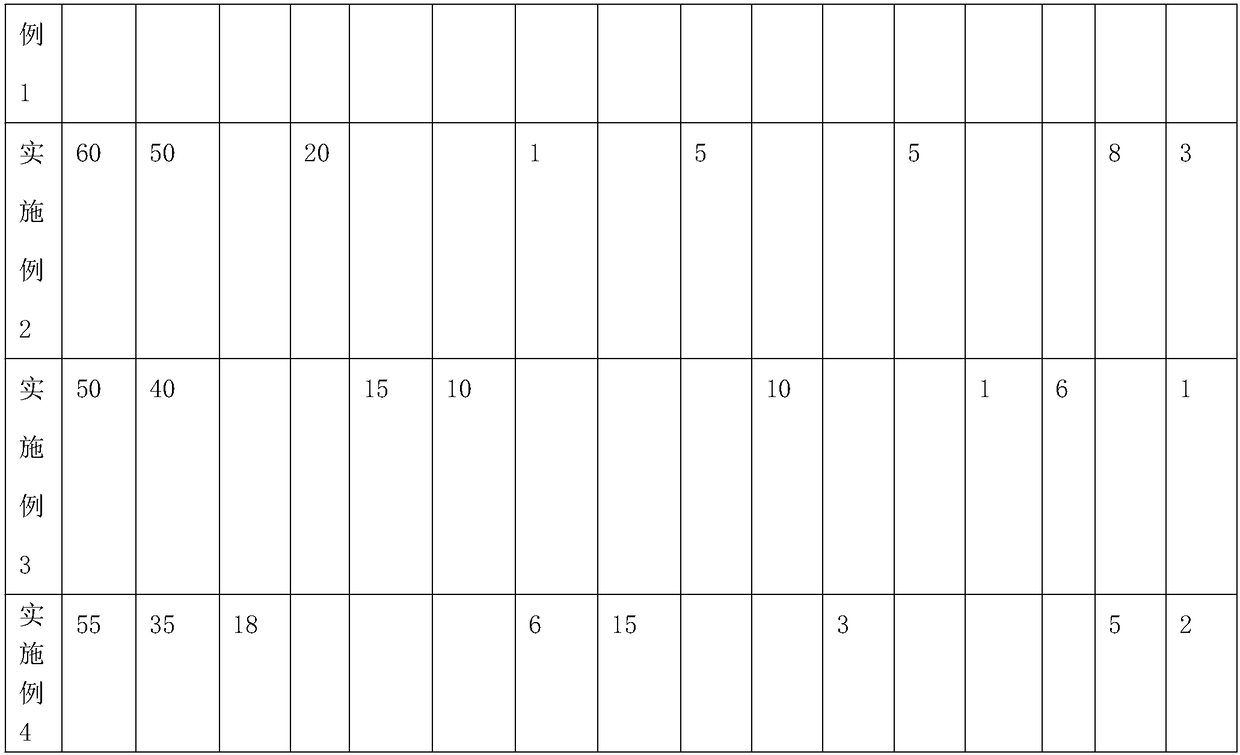

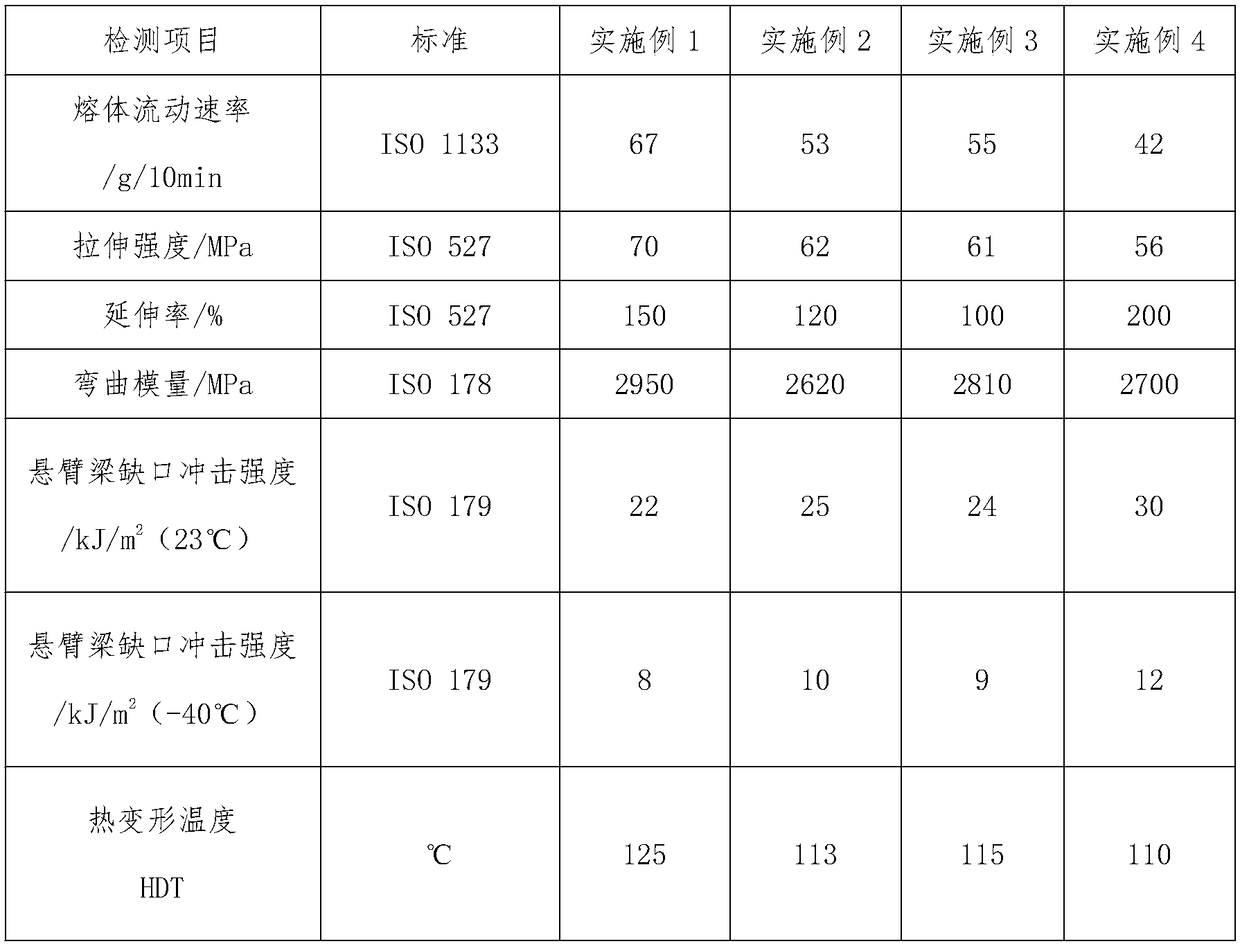

[0031] According to the specific formula in the table below and the above-mentioned preparation method, Example 1, Example 2, Example 3, and Example 4 were obtained, wherein the melt index described below is the melt flow rate of polylactic acid at 200°C and a load of 2.16kg. Polylactic acid in embodiment 1 is 200 ℃, and the melt flow rate under 2.16kg load is that melt index is 80g / 10min, and PVA alcoholysis degree is 92%, and in other additives, antioxidant is 10101 parts, graphene 0.5 part, light 38080.5 parts of stabilizing agent; Polylactic acid melt index is 50g / 10min among the embodiment 2, and PVA alcoholysis degree is 88%, and antioxidant is 10981 parts in other auxiliary agents, 1.5 parts of carbon nanotubes, 38080.5 parts of light stabilizers; Implementation Polylactic acid melt index is 60g / 10min in example 3, and PVA alcoholysis degree is 95%, antioxidant is 1680.3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com