High-performance polyurethane synthesizing sleeper and preparation method thereof

A polyurethane and high-performance technology, which is applied in the field of high-performance polyurethane synthetic sleepers and its preparation, can solve the problems of low transverse shear force, high brittleness, and large internal voids, etc., so as to improve product stability and fatigue resistance Performance, well-mixed and homogeneous results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

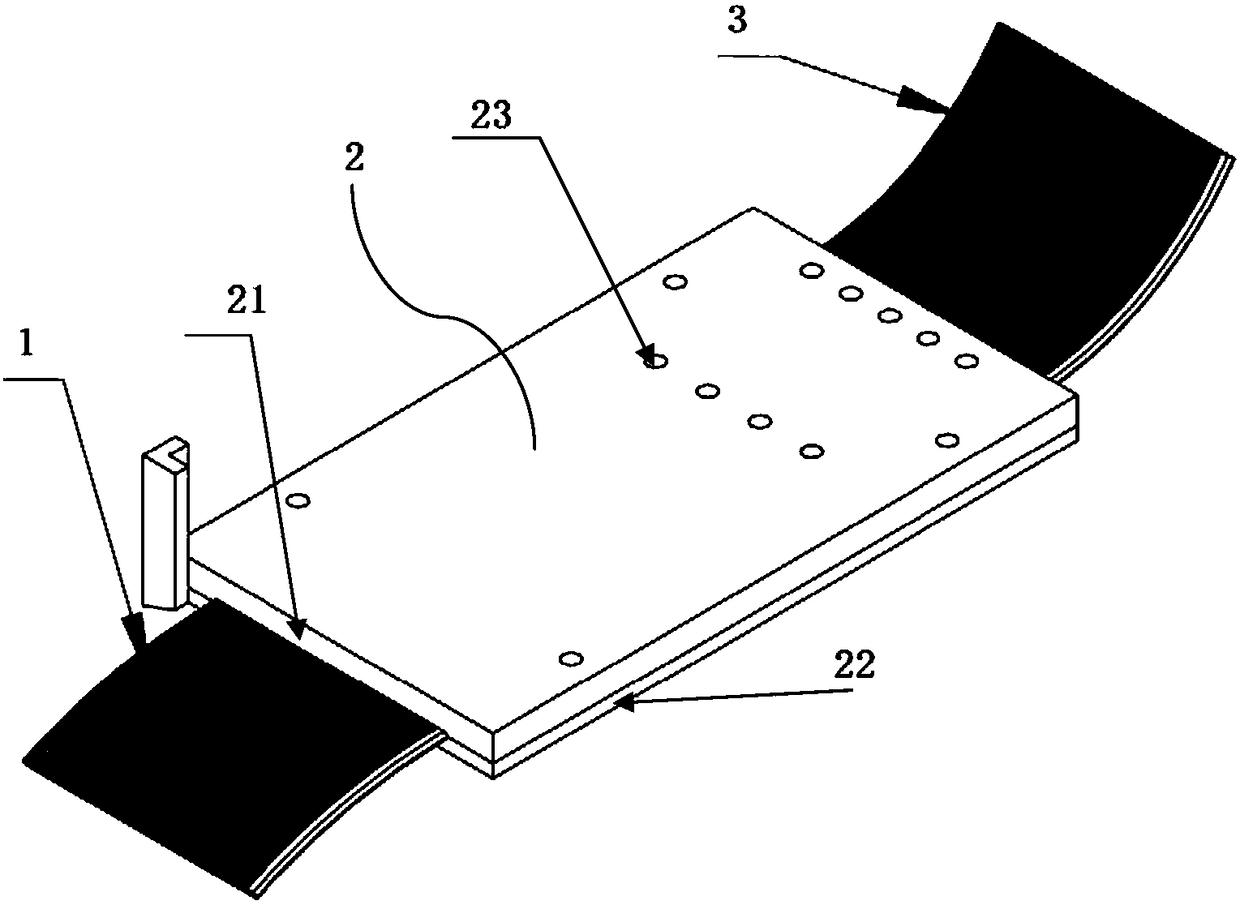

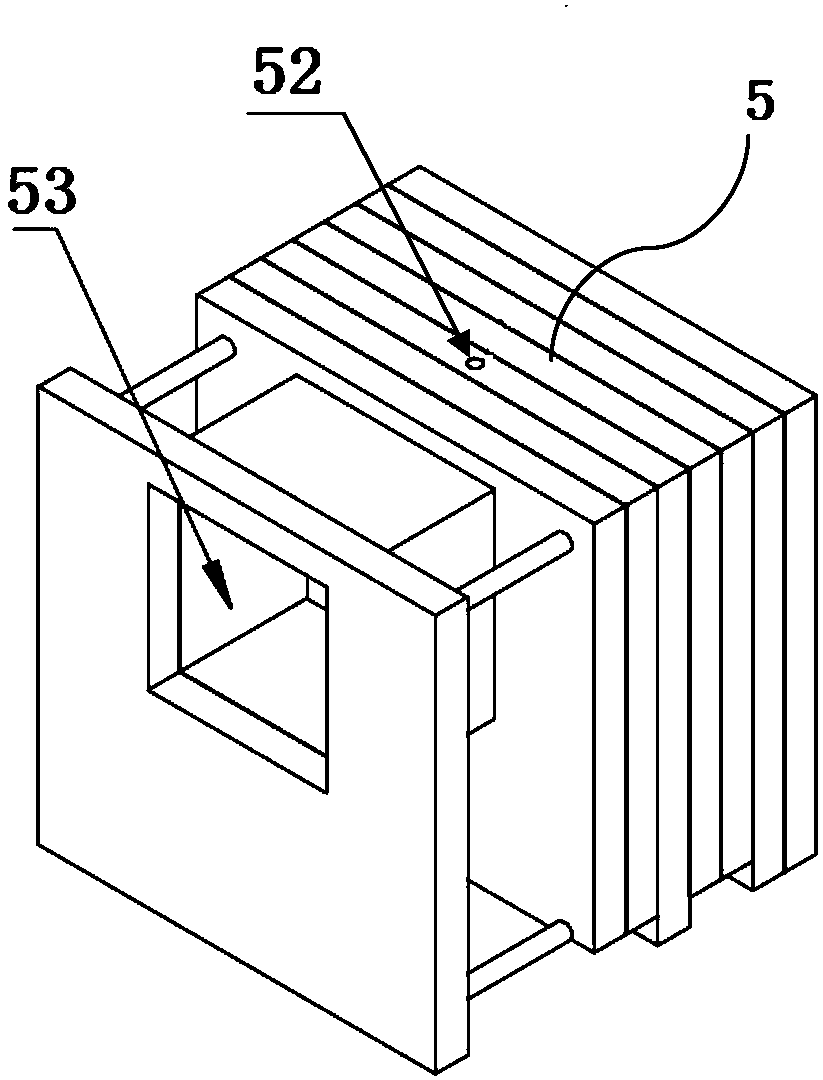

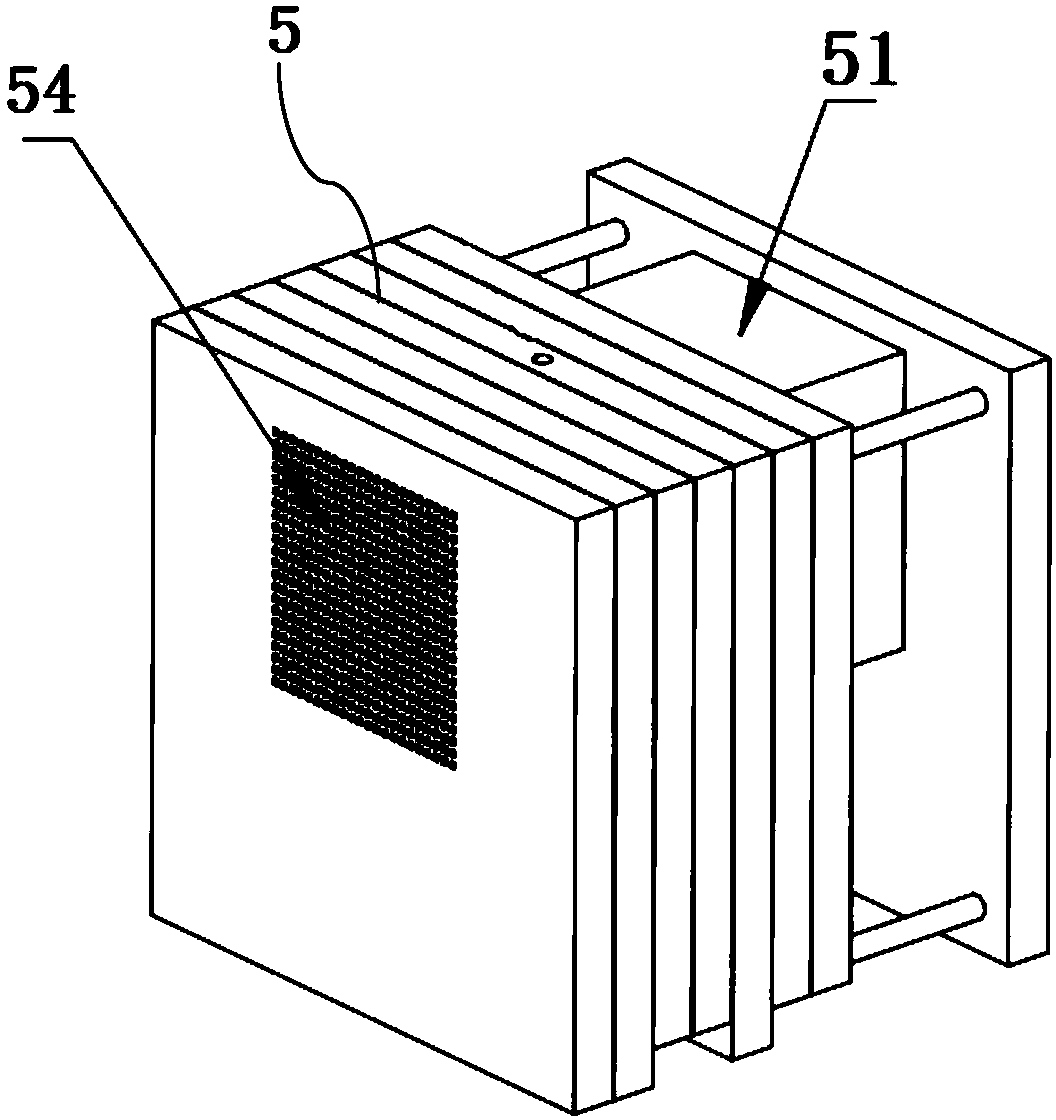

[0024] A high-performance polyurethane synthetic sleeper, the sleeper uses glass fiber as the skeleton, and the glass fiber is impregnated in foamed polyurethane to obtain the foamed base material of the sleeper. After further processing, the sleeper is obtained. The foamed polyurethane comprises the following parts by weight Component: 60 parts of polyether polyol A, 10 parts of polyether polyol B, 40 parts of polyester polyol, 10 parts of flame retardant, 0.2 part of accelerator, 0.1 part of antioxidant, 0.1 part of ultraviolet absorber, foam 1 part of stabilizer, 0.3 part of nanometer cellulose, 92 parts of isocyanate. The hydroxyl value of the polyether polyol A is 410-480, and the molecular weight is 3000-4000; the hydroxyl value of the polyether polyol B is 40-80, and the molecular weight is 1200-1500; The hydroxyl value of the ester polyol is 410-550, and the molecular weight is 4000-5000. The nanometer cellulose has a diameter of 1-50 nm, and includes glass fiber, carb...

Embodiment 2

[0039] The synthetic sleeper blank product B for urban rail transit is produced according to the formula and process of the present invention.

[0040] In parts by mass, the formula of polyurethane resin and the ratio of polyurethane resin to reinforcing fiber are as follows: polyether polyol A 51 parts, polyether polyol B 20 parts, polyester polyol 60 parts, flame retardant 15 parts, accelerator 0.4 Parts, 0.3 parts of antioxidants, 0.3 parts of ultraviolet absorbers, 3 parts of foam stabilizers, 0.5 parts of nano-sized cellulose, 100 parts of isocyanate. The hydroxyl value of the polyether polyol A is 410-480, and the molecular weight is 3000-4000; the hydroxyl value of the polyether polyol B is 40-80, and the molecular weight is 1200-1500; The hydroxyl value of the ester polyol is 410-550, and the molecular weight is 4000-5000. The diameter of the nanometer fiber is 1-50nm, including glass fiber, carbon fiber and aramid fiber. The glass fiber used as the skeleton is a high-d...

Embodiment 3

[0049] A synthetic sleeper blank C for heavy-duty railways manufactured according to the formula and forming process of the present invention.

[0050] In parts by mass, the formula of polyurethane resin and the ratio of polyurethane resin to reinforcing fiber are as follows: polyether polyol A 55 parts, polyether polyol B 15 parts, polyester polyol 36 parts, flame retardant 12 parts, accelerator 0.3 Parts, 0.2 part of antioxidant, 0.2 part of ultraviolet absorber, 2 part of foam stabilizer, 0.4 part of nano-sized cellulose, 96 part of isocyanate. The hydroxyl value of the polyether polyol A is 410-480, and the molecular weight is 3000-4000; the hydroxyl value of the polyether polyol B is 40-80, and the molecular weight is 1200-1500; The hydroxyl value of the ester polyol is 410-550, and the molecular weight is 4000-5000. The nanometer cellulose has a diameter of 1-50 nm, and includes glass fiber, carbon fiber, and aramid fiber. The glass fiber used as the skeleton is a high-de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com