Method for degrading lignin and model compound thereof through photocatalytic oxidation

A model compound, photocatalytic oxidation technology, applied in the field of biomass, can solve the problems of difficult operation, high energy consumption, and achieve the effect of high-efficiency catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

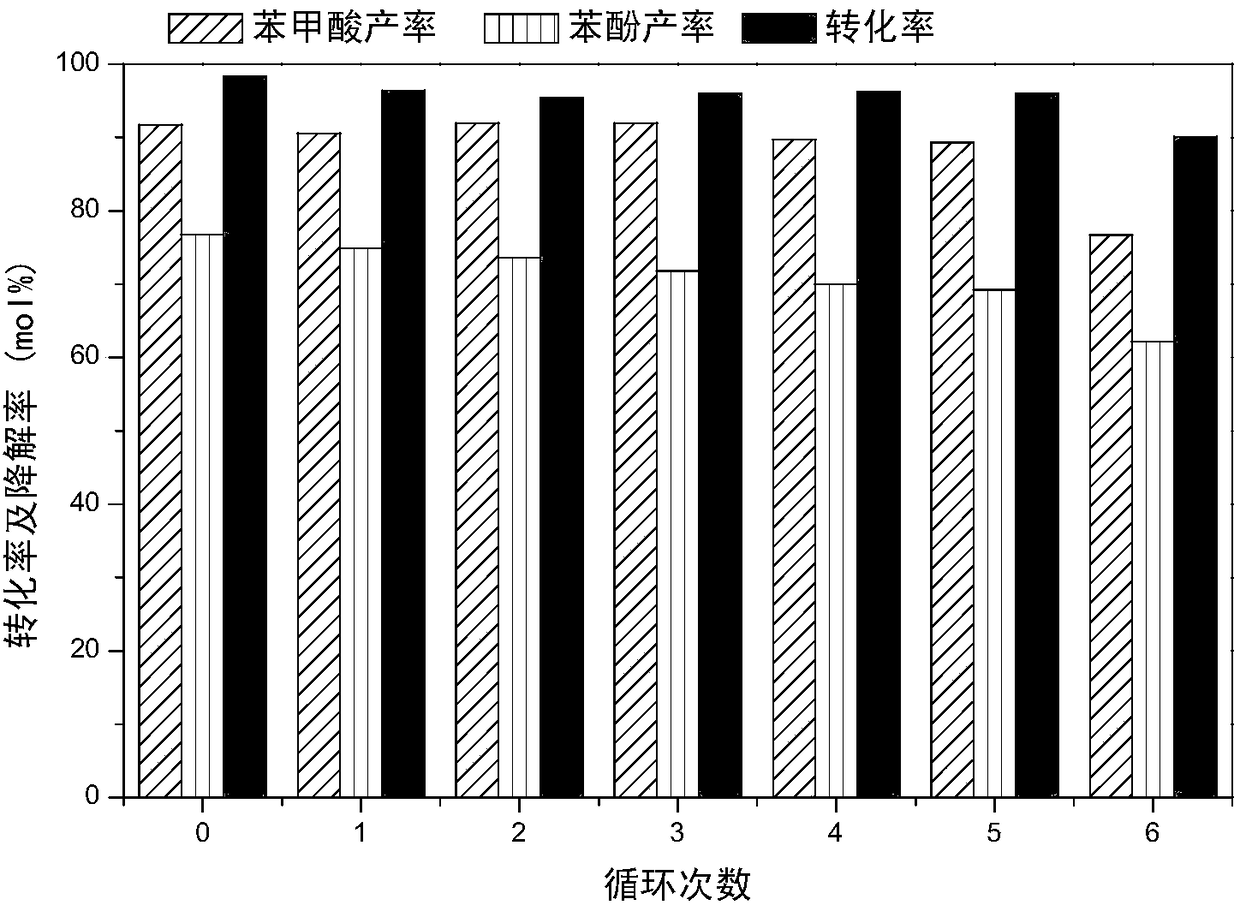

Examples

Embodiment 1

[0031] To the dried 500mg ionic liquid [CPMim]NTf 2 Add 10mg [PrSO 3 HMim]OTf, 10mg lignin model compound A 1 and 20mg of deionized water, under normal pressure air conditions, natural light irradiation, magnetic stirring at 80°C for 1.5h, after the reaction, add 4×2mL methyl tert-butyl ether to the system for extraction and separation. The extracted product was qualitatively and quantitatively analyzed by ultra-high performance liquid chromatography. The analysis results showed that A 1 There is almost no conversion, no phenol and benzoic acid are formed.

Embodiment 2

[0033] To the dried 500mg ionic liquid [CPMim]NTf 2 Add 10mg [PrS O3 HMim]OTf, 10mg lignin model compound A 2 and 20mg of deionized water, under normal pressure air conditions, natural light irradiation, magnetic stirring at 80°C for 1.5h, after the reaction, add 4×2mL methyl tert-butyl ether to the system for extraction and separation. The extracted product was qualitatively and quantitatively analyzed by ultra-high performance liquid chromatography. The analysis results showed that the conversion rate of lignin model compounds was 72.7%, and the yields of benzoic acid and phenol were 59.8% and 71.4%, respectively.

Embodiment 3

[0035] To the dried 500mg ionic liquid [CPMim]NTf 2 Add 10mg [PrS O3 HMim]OTf, 10mg lignin model compound A 2 And 5mg deionized water, under normal pressure air conditions, 254nm wavelength light source irradiation, the radiation energy is 500μW / cm 2 , magnetically stirred at 80°C for 1.5h, after the reaction, 4×2mL methyl tert-butyl ether was added to the system for extraction and separation. The extracted product was qualitatively and quantitatively analyzed by ultra-high performance liquid chromatography. The analysis results showed that the conversion rate of lignin model compounds was 92.6%, and the yields of benzoic acid and phenol were 52.2% and 86.0%, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com