A method for producing tellurium bronze rods using a horizontal continuous casting process

A production method, a technology of horizontal continuous casting, applied in the field of smelting and casting, can solve the problems not involving tellurium bronze rods, etc., and achieve the effects of eliminating the extrusion process, short process flow and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

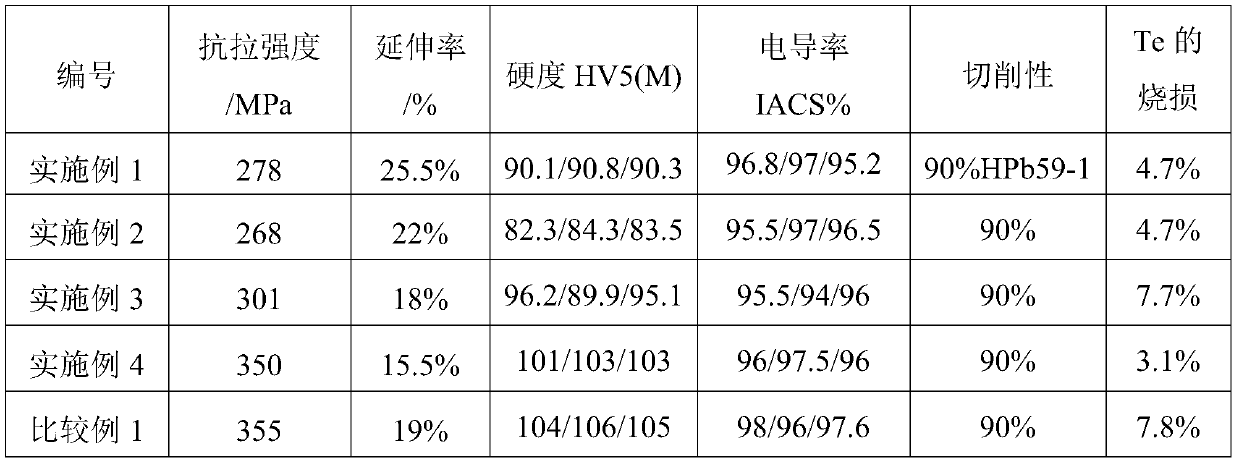

Examples

Embodiment 1

[0037] According to the composition of 0.65% Te, 0.01% P, 0.008% Mg, 0.035% rare earth, and the balance of Cu, the batching amount for each furnace is 280kg;

[0038] First put the red copper row in the 300kg melting furnace (intermediate frequency furnace), after melting, cover the surface with 8-10 cm charcoal (drying), and keep warm for more than 0.5h;

[0039] The copper liquid is transferred into the holding furnace, and charcoal is added to cover it at the same time, with a thickness of more than 10 cm, and then the phosphor-bronze master alloy wrapped with copper foil (phosphorus accounts for 16wt%) and magnesium block are added to carry out degassing and purification, refining and degassing Finally, put pure tellurium (packaged with copper foil, Te>99.5wt%) into the copper liquid, and press the tellurium into the copper liquid with a graphite cover to melt. The above-mentioned steps are all kept for 15 minutes, and the temperature is controlled at 1200 ° C;

[0040] Afte...

Embodiment 2

[0043] According to the composition of 0.55% Te, 0.01% P, 0.01% Mg, 0.03% rare earth, and the balance of Cu, the batching amount for each furnace is 280kg;

[0044] First, put the red copper row in the 300kg smelting furnace. After melting, cover the surface with 8-10cm charcoal (drying), and keep it warm for more than 0.5h;

[0045] The copper liquid is transferred to the holding furnace, and charcoal is added to cover it at the same time, with a thickness of more than 10 cm, and then the phosphor-bronze master alloy (phosphorus accounts for 18wt%) and magnesium blocks wrapped in copper foil are added to carry out degassing and purification, refining and degassing Finally, put pure tellurium (packaged with copper foil, Te>99.5wt%) into the copper liquid, and press the tellurium into the copper liquid with a graphite cover to melt. The above steps are all kept at 15 minutes, and the temperature is controlled at 1230 ° C;

[0046] After the composition of the copper liquid is a...

Embodiment 3

[0049] According to the composition of 0.45% Te, 0.05% P, 0.01% Mg, 0.025% rare earth, and the balance of Cu, the batching amount for each furnace is 280kg;

[0050] First, put the red copper row in the 300kg smelting furnace. After melting, cover the surface with 8-10cm charcoal (drying), and keep it warm for more than 0.5h;

[0051] The copper liquid is transferred into the holding furnace, and charcoal is added to cover it at the same time, with a thickness of more than 10 cm, and then the phosphor-bronze master alloy (phosphorus accounts for 14wt%) and magnesium blocks wrapped in copper foil are added to carry out degassing and purification, refining and degassing Finally, put pure tellurium (packaged with copper foil, Te>99.5wt%) into the copper liquid, and press the tellurium into the copper liquid with a graphite cover to melt. The above steps are all kept warm for 15 minutes, and the temperature is controlled at 1250 ° C;

[0052] After the composition of the copper li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com