Processing method for metal barrel lacy sealing cover

A processing method and technology of metal barrels, applied in metal processing equipment, manufacturing tools, feeding devices, etc., can solve the problems of no identical patent technical documents, high labor intensity of workers, and difficulty in quality assurance, so as to reduce labor intensity and the number of labor, simple structure, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

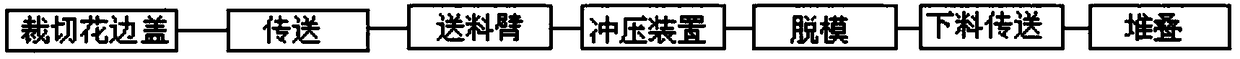

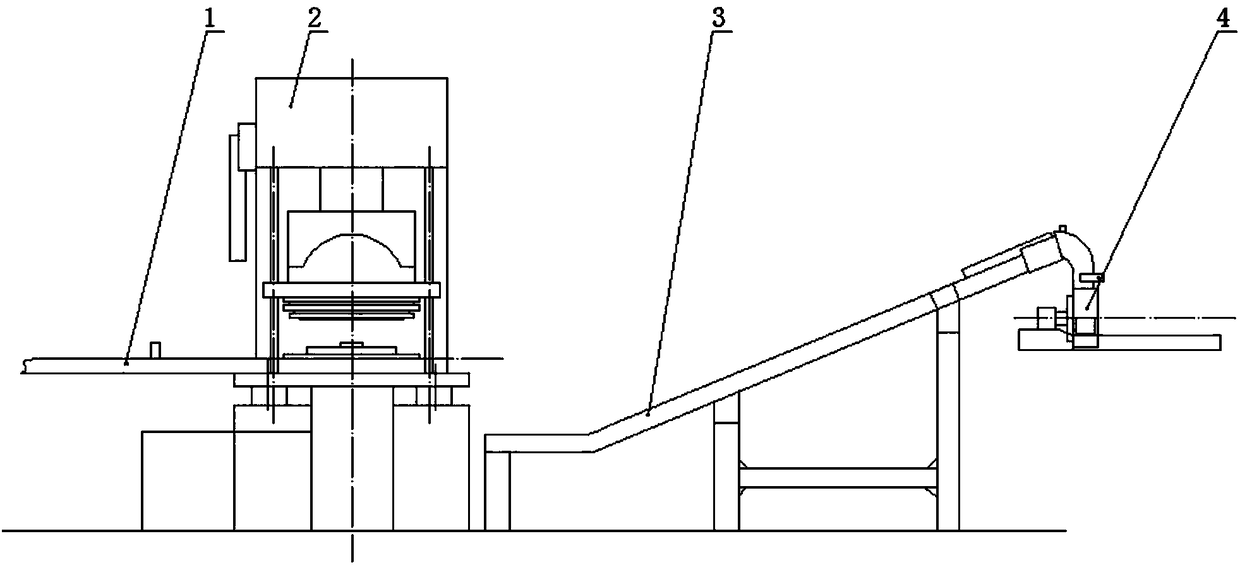

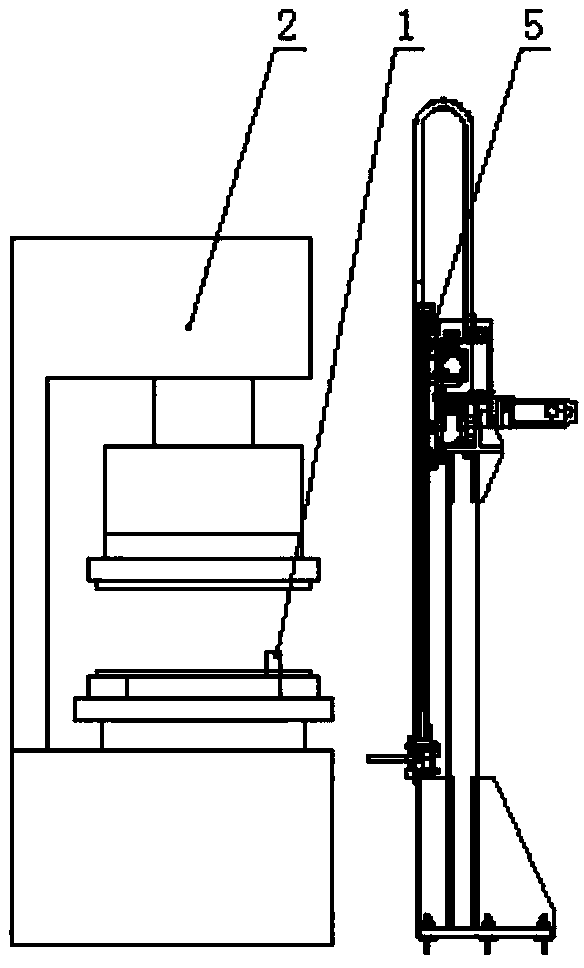

[0031] A metal barrel lace capping processing system, see attached Figures 1 to 2 As shown, it includes a raw material conveyor belt 1, a stamping device 2, a blanking conveyor 3, a stacking device 4, and a feeding robot 5. The raw material conveyor belt, stamping device, blanking conveyor, and stacking device are sequentially arranged from the input to the output direction. A feeding manipulator is installed in front of the device, and the working range of the feeding manipulator covers the output end of the raw material conveyor belt, the stamping device and the input end of the unloading conveying device.

[0032] For the specific structure of the stamping device, see the attached Figure 4 to F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com