Three-way catalyst for treatment of tail gas of automobile and preparation method thereof

A three-way catalyst and automobile exhaust technology, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of complex catalyst preparation process, easy loss of active components, and easy sintering of precious metals, etc. To achieve the effect of inhibiting precious metal agglomeration, reducing migration and firm adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

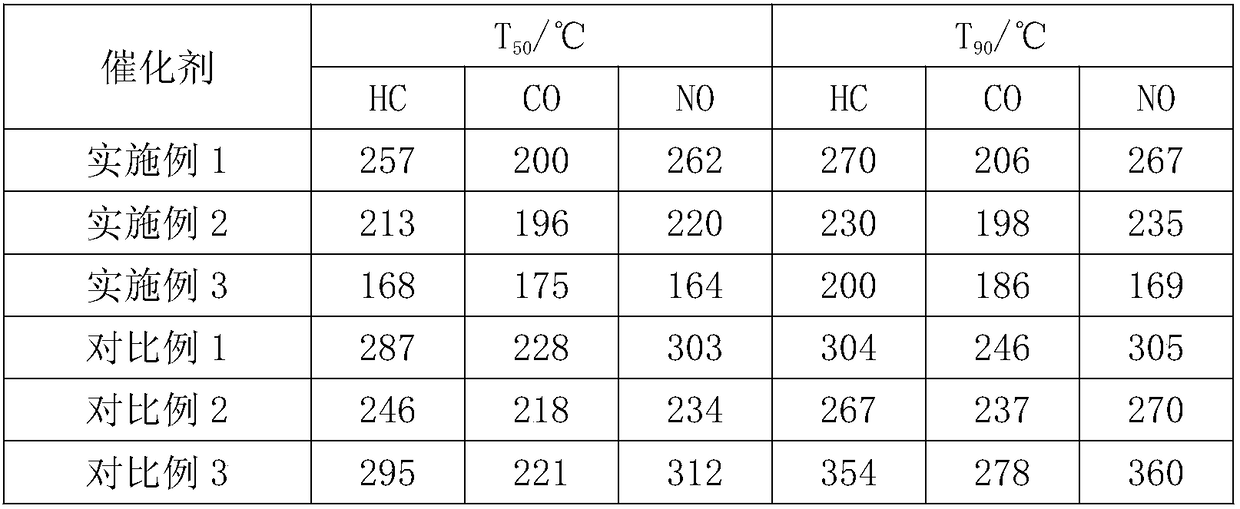

Examples

preparation example Construction

[0021] A preparation method of a three-way catalyst for automobile exhaust gas treatment includes the following steps:

[0022] (1) Preparation of Pd layer slurry: first dissolve the rare earth additive nitrate with an appropriate amount of deionized water, and then add the cerium-zirconium composite oxide and modified γ-Al 2 O 3 After stirring uniformly, add palladium nitrate solution, stir for 12-24 hours, add binder, continue to stir for 30-60min, adjust the pH value, and add water to adjust to the required solid content, then ball mill for 30min-60min to obtain Pd layer slurry material;

[0023] (2) Preparation of Rh layer slurry: first dissolve the rare earth additive nitrate with an appropriate amount of deionized water, and then add the cerium-zirconium composite oxide and modified γ-Al 2 O 3 After stirring uniformly, add rhodium nitrate solution, stir for 12-24 hours, add binder, continue to stir for 30-60min, adjust the pH value, and add water to adjust to the required soli...

Embodiment 1

[0039] After dissolving 1.8g of zirconium nitrate in 70g of water, add 19g of γ-Al modified by La 2 O 3 Mix well with 29g of cerium-zirconium composite oxide, dilute 2.2g of palladium nitrate by 1 time and slowly add dropwise to the slurry, stir for 12 hours; after stirring, add 1.4g of binder, stir for 30min, and adjust the pH to 3. After adding 18g of water, ball mill for 30min to obtain Pd layer slurry;

[0040] After dissolving 1.4g zirconium nitrate in 55g water, add 15g γ-Al modified by La 2 O 3 Mix with 23g of cerium-zirconium composite oxide uniformly, dilute 0.46g of rhodium nitrate twice and slowly add dropwise to the slurry, and stir for 12 hours; after the stirring, add 1.1g of binder, stir for 30min, and adjust the pH to 3. After adding 16g of water, ball mill for 30 minutes to obtain Rh layer slurry;

[0041] The honeycomb specification is 101.6mm in diameter, 62mm in height, and 600 meshes in cell density. The Pd layer is applied to the two ends of the honeycomb by ...

Embodiment 2

[0044] After dissolving 1.8g zirconium nitrate and 1.3g neodymium nitrate in 70g water, add 19g γ-Al modified by La 2 O 3 Stir and mix with 29g of cerium-zirconium composite oxide, take 2.67g of palladium nitrate solution with a concentration of 17.91%, slowly add dropwise to the slurry after dilution, and stir for 24 hours; after stirring, add 1.4g of binder and stir for 60min, Adjust the pH to 4, add 18g of water and then ball mill for 50min, and add the Pd layer slurry;

[0045] After dissolving 1.4g zirconium nitrate and 1.0g praseodymium nitrate in 60g water, add 15g γ-Al modified by La 2 O 3 Stir and mix 23g of cerium-zirconium composite oxide evenly, take 0.56g of rhodium nitrate solution with a concentration of 9.47%, slowly add dropwise to the slurry after dilution, and stir for 24 hours; after stirring, add 1.1g of binder and stir for 60min, Adjust the pH to 4, add 16 g of water and then ball mill for 50 minutes to obtain Rh layer slurry.

[0046] The honeycomb specificat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com