Reactor pressure vessel bolt hole multi-camera video inspection device

A multi-camera and pressure vessel technology, applied to television systems, televisions, and color televisions that adapt to optical transmission, can solve problems such as long inspection times, and achieve the effects of shortened working hours, improved efficiency, and simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

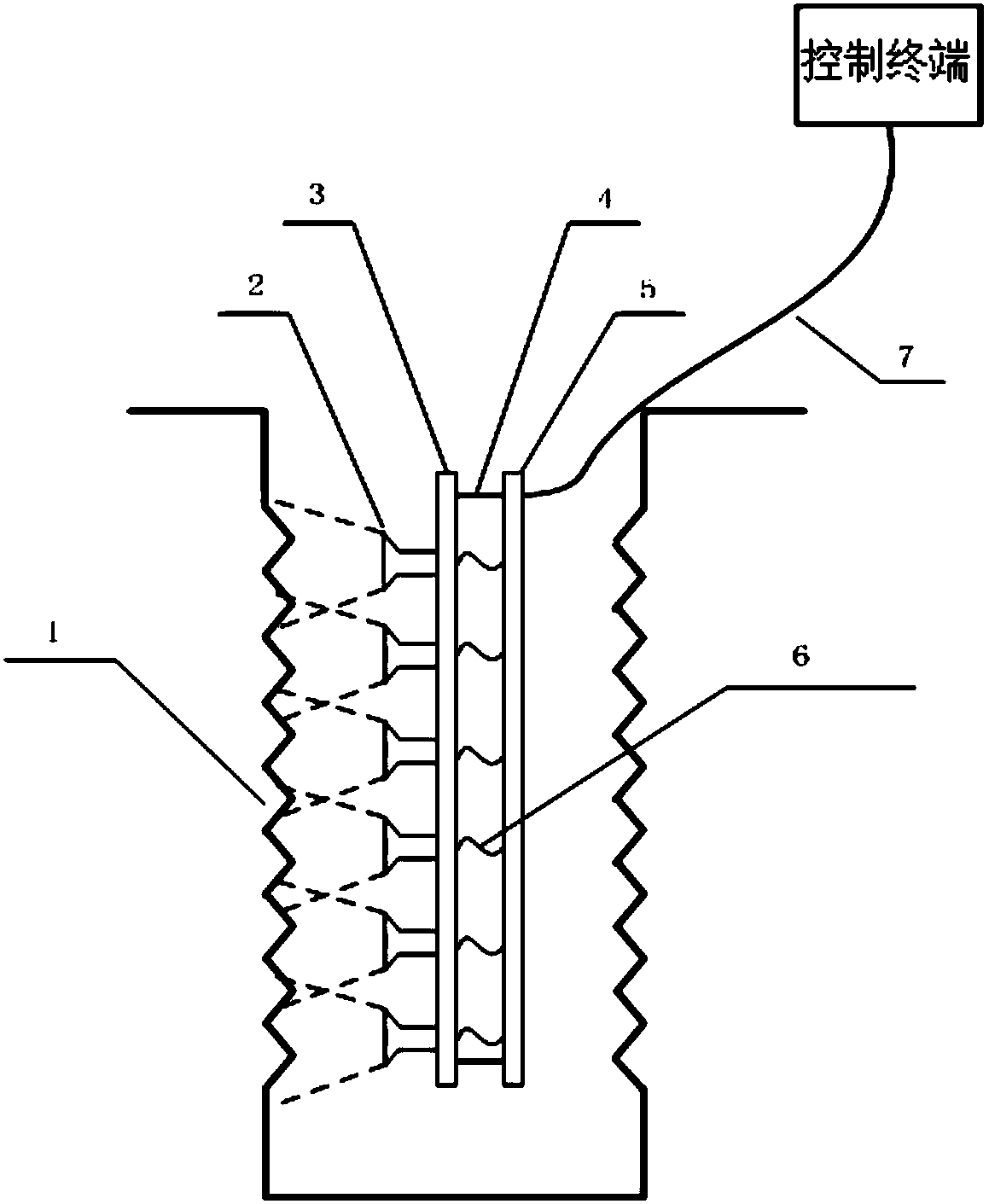

[0023] like figure 1 As shown, a multi-camera video inspection device for reactor pressure vessel bolt holes includes: camera 2, multi-camera fixing bracket 3, connecting bracket 4, data fusion board 5, connecting wire 6 and data transmission optical cable. The cameras 2 are vertically arranged on the multi-camera fixed bracket 3 from top to bottom, and the multi-camera fixed bracket 3 is mechanically fixedly connected to the data fusion board 5 through the connection bracket 4. A data line 6 is used to transmit the image collected by the camera 2 to the data fusion board 5 through the data line 6, and the data fusion board 5 transmits the fused data to the control terminal through the optical fiber cable 7 for processing.

[0024] Wherein, the camera 2 specifically includes six megapixel-level industrial cameras, which are verticall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com