Method for synthesizing FeF3/CNTs positive electrode material by liquid phase method

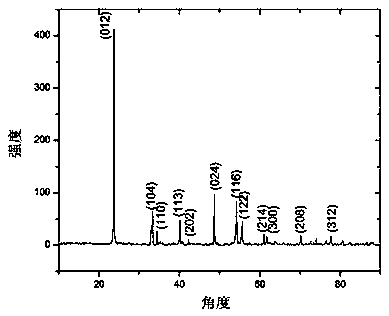

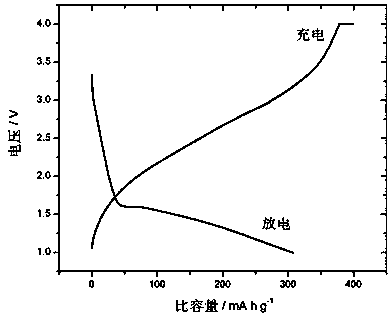

A positive electrode material and liquid phase method technology, which is applied in the field of FeF3/CNTs positive electrode material synthesis by liquid phase method, can solve the problems of insufficient electrochemical performance, poor electrochemical performance, wide energy band gap, etc., and achieve particle size Small size, good electrical conductivity, and high charge-discharge specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A liquid-phase method for synthesizing FeF 3 / CNTs positive electrode material method, the specific steps are:

[0026] (1) Disperse 1.5g of carbon nanotubes in 25mL of nitric acid with a mass fraction of 68% and 25mL of sulfuric acid with a mass fraction of 98% according to the ratio of mass volume ratio g:mL of 3:100, Magnetically stirred at room temperature for 3 h to obtain a mixed solution A;

[0027] (2) Measure hydrofluoric acid equal to the volume of mixed solution A with a mass fraction of 30%, slowly add it to mixed solution A, stir until fully dispersed, and obtain mixed solution B;

[0028] (3) Weigh iron acetylacetonate according to the mass volume ratio g:mL of iron acetylacetonate and ethanol aqueous solution g:mL is 30:100, add 60g iron acetylacetonate and 3g surfactant polyethylene glycol (PEG) to 200mL In the ethanol aqueous solution, the ethanol aqueous solution is obtained by mixing equal volumes of ethanol and water, and is prepared as a mixed sol...

Embodiment 2

[0037] A liquid-phase method for synthesizing FeF 3 / CNTs positive electrode material method, the specific steps are:

[0038] (1) Disperse 3.2g of carbon nanotubes in a mixed acid of 60mL of nitric acid with a mass fraction of 68% and 20mL of sulfuric acid with a mass fraction of 98% according to the mass volume ratio g:mL of 4:100, Magnetically stirred at room temperature for 4 h to obtain a mixed solution A;

[0039] (2) Measure hydrofluoric acid equal to the volume of mixed solution A with a mass fraction of 30%, slowly add it to mixed solution A, stir until fully dispersed, and obtain mixed solution B;

[0040] (3) Weigh iron acetylacetonate according to the mass volume ratio g:mL of iron acetylacetonate and ethanol aqueous solution g:mL is 10:100, add 48g iron acetylacetonate and 3.36g surfactant fatty acid polyoxyethylene ester (AE) to In the 480mL ethanol aqueous solution, the ethanol aqueous solution is obtained by mixing equal volumes of ethanol and water, and is pre...

Embodiment 3

[0045] A liquid-phase method for synthesizing FeF 3 / CNTs positive electrode material method, the specific steps are:

[0046] (1) Disperse 3g of carbon nanotubes in a mixture of 40mL of nitric acid with a mass fraction of 68% and 20mL of sulfuric acid with a mass fraction of 98% according to the mass volume ratio g:mL of 5:100. Stir magnetically at room temperature for 6 h to obtain a mixed solution A;

[0047] (2) Measure hydrofluoric acid equal to the volume of mixed solution A with a mass fraction of 30%, slowly add it to mixed solution A, stir until fully dispersed, and obtain mixed solution B;

[0048] (3) According to the mass volume ratio of iron acetylacetonate and ethanol aqueous solution g:mL is 20:100, iron acetylacetonate is weighed, and 72g iron acetylacetonate and 4.32g surfactant alkylphenol polyoxyethylene ether (APEO) Add it into 360mL ethanol aqueous solution, which is obtained by mixing equal volumes of ethanol and water, and prepare mixed solution C;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com