A Method for Measuring Synthetic Temperature of Superhard Materials

A technology of superhard materials and synthetic blocks, which is applied in thermometers, measuring heat, measuring devices, etc., can solve problems such as difficult measurement of superhard material synthesis temperature, achieve good guiding significance, high measurement success rate, and not easy to break.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

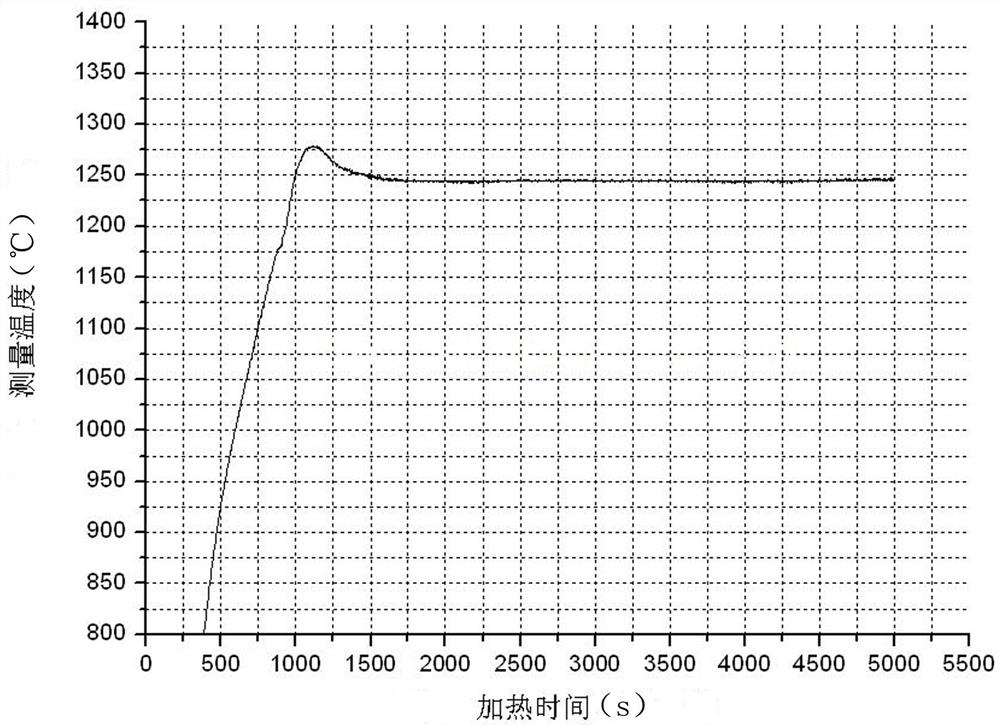

Embodiment 1

[0046] To measure the internal temperature of a certain type of diamond synthesis cavity in a Φ47mm cavity, a B-type platinum-rhodium temperature measuring wire (0.5mm in diameter) is used. The measurement temperature range is 0~1800°C, the error range is 0.25%t, the length of both ends is 100mm, and the diameter is 0.1mm. The copper wire is 23.5mm away from the middle solder point, and each side is wound with a length of 30mm. The middle part of the assembly block is drilled with a drill bit with a diameter of 3.0mm in the horizontal direction of the center part. Drill the hole well, and use the alumina coarse porcelain tube (inner diameter 2.0mm, outer diameter 2.9mm, length 47mm) to penetrate the middle hole of the assembly block, and then insert the finished thermocouple along the outside of the pre-punched hole to ensure The two ends are symmetrical, and the last two sides are covered with two thin alumina porcelain tubes (inner diameter 1.0mm, outer diameter 1.9mm, length...

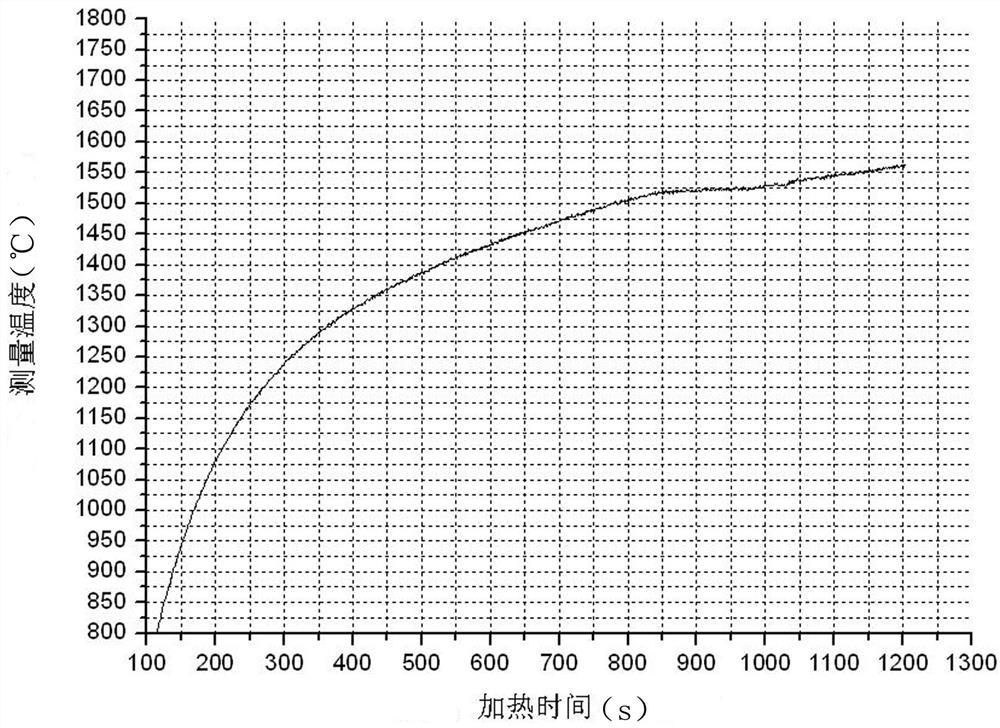

Embodiment 2

[0048] To measure the internal temperature of a certain type of cubic boron nitride synthesis cavity in a Φ40mm cavity, a tungsten-rhenium temperature measuring wire (0.1mm in diameter) is selected. The mm copper wire is 10.0mm away from the middle solder point, and each side is wound with a length of 30mm. The middle part of the assembly block is drilled with a drill bit with a diameter of 2.5mm in the horizontal direction of the center part. Drill the hole well, use the boron nitride coarse porcelain tube (inner diameter 1.8mm, outer diameter 2.8mm, length 40mm) to penetrate the middle hole of the assembly block, and then insert the finished thermocouple along the outer edge of the pre-punched hole to ensure The two ends are symmetrical, and the last two sides are covered with two fine boron nitride porcelain tubes (inner diameter 1.0mm, outer diameter 1.7mm, length 50mm), and the prepared temperature measurement assembly block is baked at 100°C for 1 hour, and placed in the ...

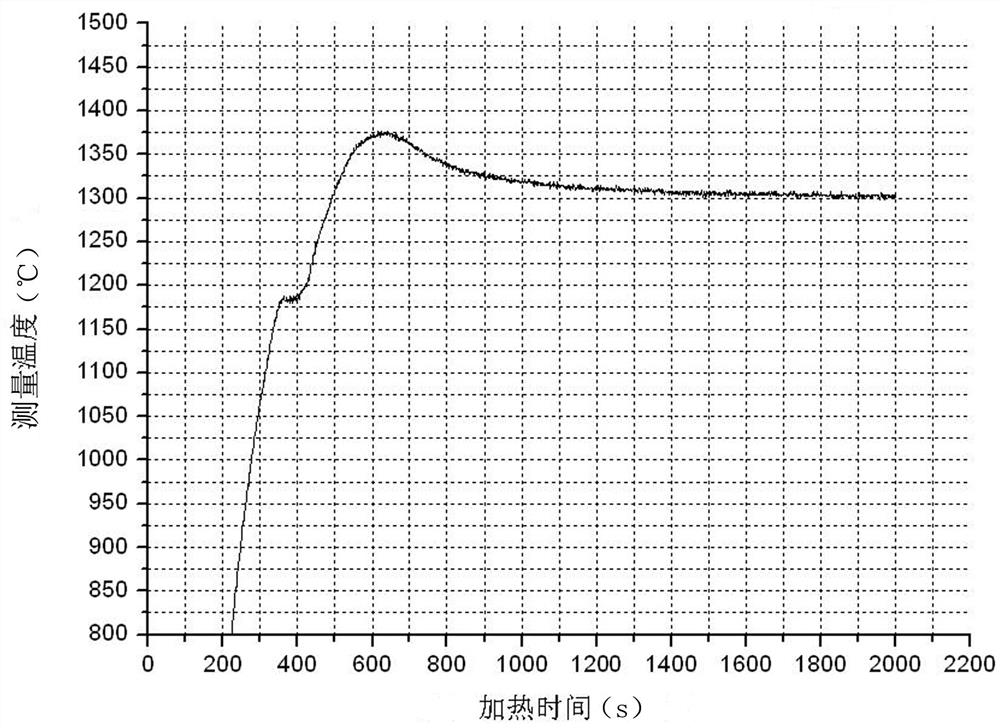

Embodiment 3

[0050] To measure the internal temperature of a certain type of diamond synthesis cavity in a Φ55mm cavity, a B-type platinum-rhodium temperature measuring wire (0.5mm in diameter) is used. The measuring temperature range is 0~1800°C, the error range is 0.25%t, the length of both ends is 120mm, and the diameter is 0.1mm. The copper wire is 27.5mm away from the middle solder point, and each side is wound with a length of 40mm. The middle part of the assembly block is drilled with a drill bit with a diameter of 3.2mm in the horizontal direction of the center part. Drill a hole with a drill bit, and use an alumina coarse porcelain tube (inner diameter 2.2mm, outer diameter 3.2mm, length 55mm) to penetrate the middle hole of the assembly block, and then insert the finished thermocouple along the outside of the pre-punched hole to ensure that both The end is symmetrical, and the last two sides are covered with two fine boron nitride porcelain tubes (inner diameter 1.2mm, outer diame...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com