Flatness returning brick masonry structure for spherical converter

A masonry structure and converter technology, applied in the field of refractory materials, can solve the problems of unsatisfactory corrosion resistance of molten steel, poor bonding of masonry joints, and a large number of brick joints, so that it is not easy for molten steel to penetrate, improve service life, and enhance safety sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings, but it should be pointed out that the implementation of the present invention is not limited to the following embodiments.

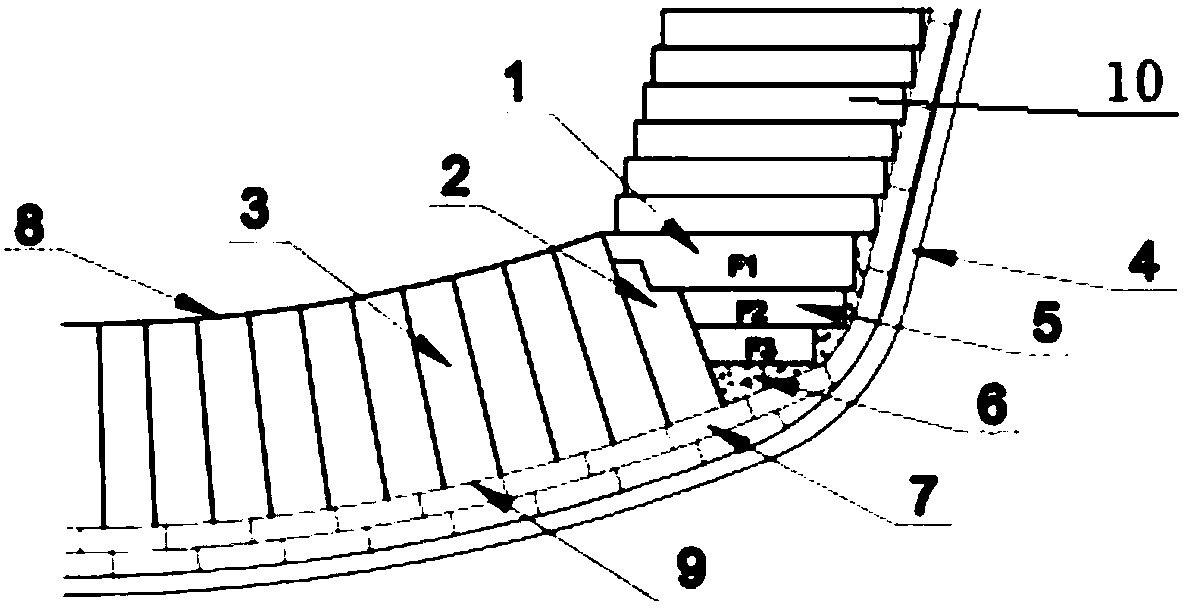

[0026] See Figure 1-Figure 9 , a spherical converter back-leveling brick masonry structure, said back-leveling bricks include back-leveling cut bricks 1 of the uppermost layer (F1) and several layers (F2, F3) of back-leveling standard bricks 5 below, said back-leveling bricks The end of the cut brick 1 is stepped, and the end of the bottom brick 2 of the last ring is a stepped shape matched with the end of the back-level cut brick 1. A stepped gap is formed between the upper end of the bottom brick 2 and the last ring of furnace bottom bricks 2; the thickness ratio of the back-level cut brick 1 to the back-level standard brick 2 is 1.5-2:1.

[0027] The flat-cut brick 1 has a stepped end, and its upper and lower end faces are inclined. Its inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com