Copolymer P, aqueous dispersion resin, and applications of aqueous dispersion resin in aqueous coating materials

A water-based dispersion, copolymer technology, applied in the direction of coating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

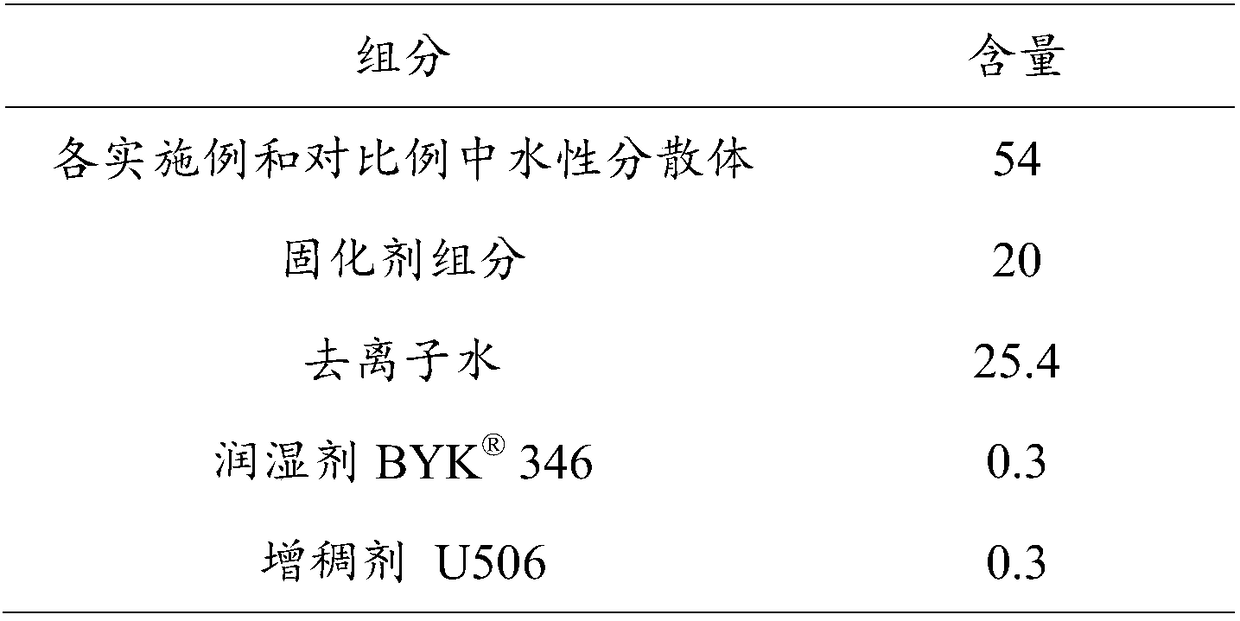

Examples

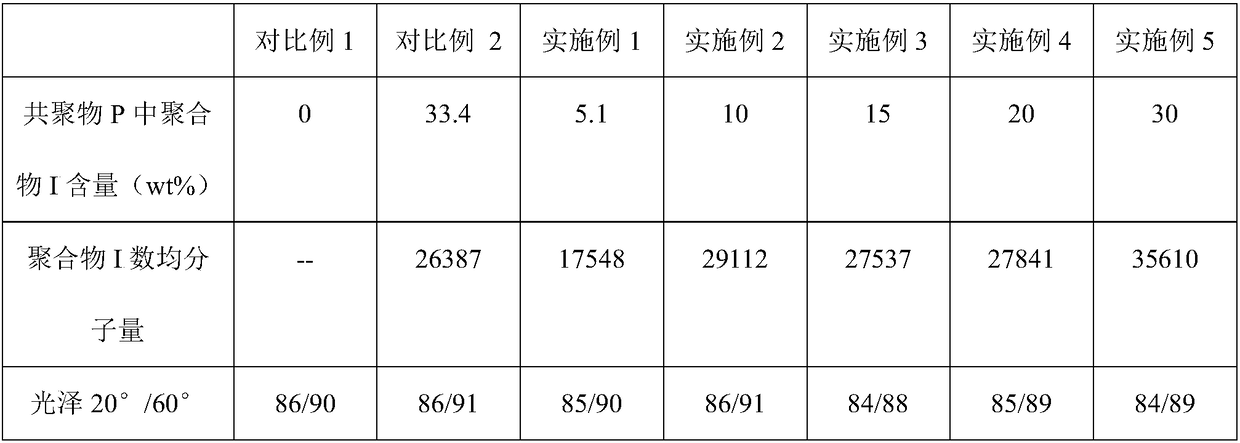

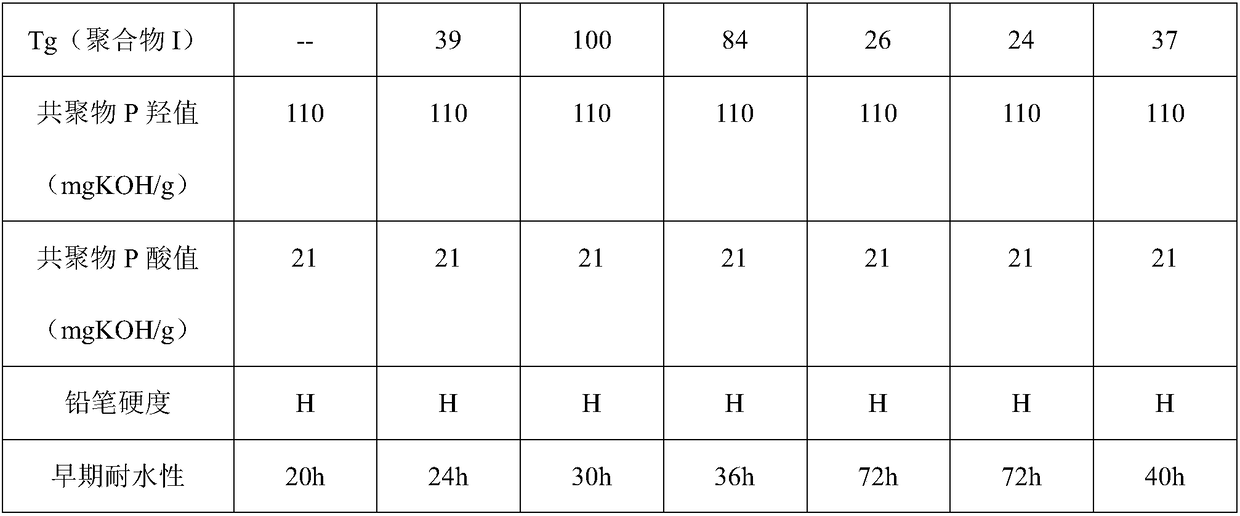

Embodiment 1

[0074] Add 240g of Pnb into the reactor containing heating device, condensing device and stirring device and heat it to 140°C. When the temperature of the initial material rises to 140°C, add 65g of styrene and 1g of DTBP into the reactor at one time. At this temperature Reaction 1-2h. After that, the following monomer mixture was evenly added dropwise in the reactor: 260g methyl methacrylate, 130g butyl acrylate, 246g hydroxyethyl methacrylate, 257g isooctyl acrylate and 26g DTBP, and the dropping time was about 3.5 hours. After the dropwise addition of the monomer mixture was completed, the temperature was kept at this temperature for 1 hour. Then the following monomer mixture is evenly added dropwise in the reactor: 140g methyl methacrylate, 58g butyl acrylate, 73g hydroxyethyl methacrylate, 34.2g acrylic acid and 6g DTBP, the time for adding is about 1 hour, and wait for After the dropwise addition of the monomer mixture, keep at this temperature for 1 hour, cool down to ...

Embodiment 2

[0076] Add 240g of Pnb into the reactor containing heating device, condensing device and stirring device and heat it to 140°C. When the temperature of the initial material rises to 140°C, add 95g of isobornyl methacrylate and 37g of acrylic acid into the reactor at one time Ethyl ester and 2g DTBP, react at this temperature for 1-2h. After that, the following monomer mixture was evenly added dropwise in the reactor: 230g methyl methacrylate, 130g butyl acrylate, 246g hydroxyethyl methacrylate, 220g isooctyl acrylate and 25gDTBP, and the time for adding was about 3.5 hours. After the monomer mixture was added dropwise, it was kept at this temperature for 1 hour. Then the following monomer mixture is evenly added dropwise in the reactor: 140g methyl methacrylate, 58g butyl acrylate, 73g hydroxyethyl methacrylate, 34.2g acrylic acid and 6g DTBP, the time for adding is about 1 hour, and wait for After the dropwise addition of the monomer mixture, keep at this temperature for 1 ho...

Embodiment 3

[0078]Add 240g of Pnb into the reactor containing heating device, condensing device and stirring device and heat it to 140°C. When the temperature of the initial material rises to 140°C, add 133g of styrene, 56g of isooctyl acrylate and 2g of DTBP, dropping time 0.5h. After that, the following monomer mixture was evenly added dropwise in the reactor: 174g methyl methacrylate, 126g butyl acrylate, 246g hydroxyethyl methacrylate, 220g isooctyl acrylate and 25g DTBP, and the dropping time was about 3.5 hours. After the dropwise addition of the monomer mixture was completed, the temperature was kept at this temperature for 1 hour. Then the following monomer mixture is evenly added dropwise in the reactor: 140g methyl methacrylate, 58g butyl acrylate, 73g hydroxyethyl methacrylate, 34.2g acrylic acid and 6g DTBP, the time for adding is about 1 hour, and wait for After dropping the monomer mixture, keep it at this temperature for 1 hour, lower the temperature to 110°C, add 85.3g of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com