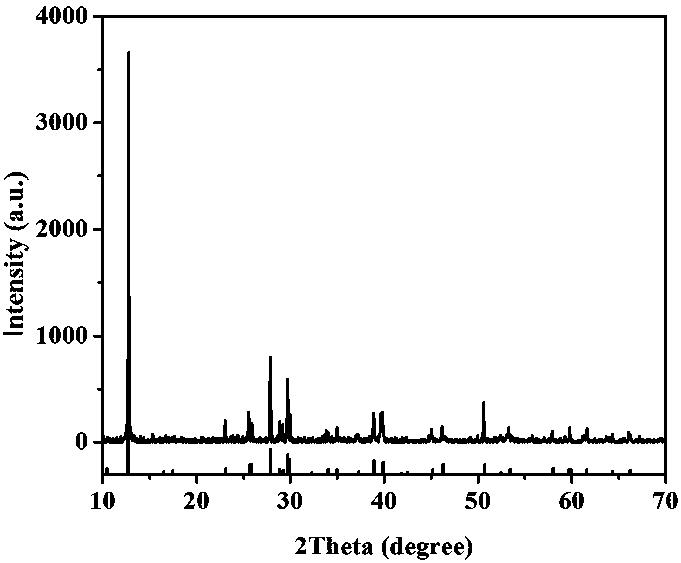

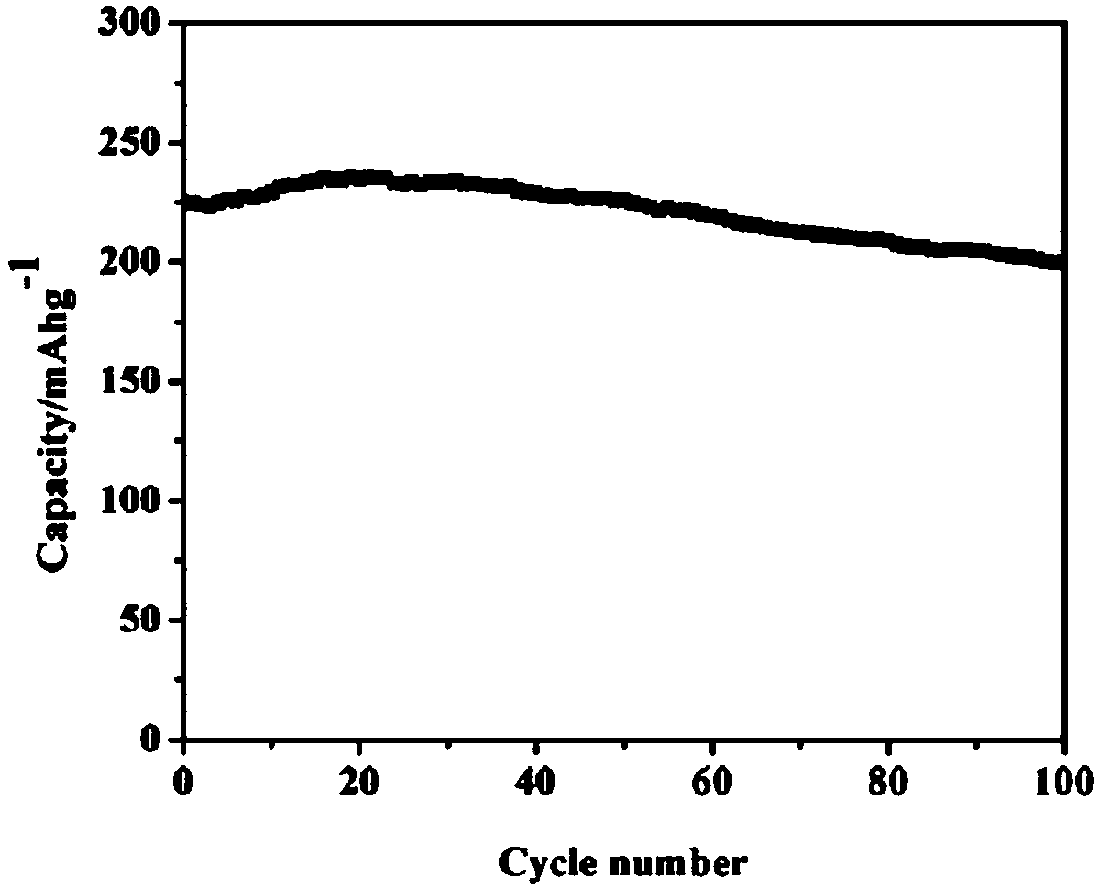

Preparation method of positive pole material Na1.1V3O7.9 of lithium ion battery

A certain amount and molecular weight technology, applied in the direction of battery electrodes, secondary batteries, chemical instruments and methods, etc., can solve the problems of poor cycle stability of vanadium-based positive electrode materials, and achieve simple and easy-to-operate production processes and processes, and cheap and easy-to-use materials The effect of obtaining and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) Weigh a certain amount of V 2 o 5 (molecular weight 181.88, analytically pure) put into distilled water and stir and heat to 80°C to prepare solution A, V 2 o 5 The mass ratio of oxalic acid to distilled water is 3:100; weigh a certain amount of oxalic acid and dissolve it in distilled water to make solution B, the mass ratio of oxalic acid to distilled water is 6:100, oxalic acid and V 2 o 5 The molar ratio is 3:1;

[0021] (2) Slowly add the above-mentioned solution B to the solution A, heat and stir the solution to 100°C, the solution turns blue and transparent, then continue to stir and keep warm for 1 hour to obtain the solution C;

[0022] (3) Weigh a certain amount of NaNO according to the V:Na molar ratio of 3:1.1 3 (Molecular weight 84.99, analytically pure) soluble in distilled water, NaNO 3 The mass ratio to distilled water is 1:50. After stirring for 10 minutes, the solution D is obtained, and the solution D is slowly added dropwise to the solution...

Embodiment 2

[0025] (1) Weigh a certain amount of V 2 o 5 (molecular weight 181.88, analytically pure) put into distilled water and stir and heat to 80°C to prepare solution A, V 2 o 5The mass ratio of oxalic acid to distilled water is 3:100; weigh a certain amount of oxalic acid and dissolve it in distilled water to make solution B, the mass ratio of oxalic acid to distilled water is 6:100, oxalic acid and V 2 o 5 The molar ratio is 3:1;

[0026] (2) Slowly add the above-mentioned solution B to the solution A, heat and stir the solution to 100°C, the solution turns blue and transparent, then continue to stir and keep warm for 1 hour to obtain the solution C;

[0027] (3) Weigh a certain amount of NaNO according to the V:Na molar ratio of 3:1.1 3 (Molecular weight 84.99, analytically pure) soluble in distilled water, NaNO 3 The mass ratio to distilled water is 1:50. After stirring for 10 minutes, the solution D is obtained, and the solution D is slowly added dropwise to the solution ...

Embodiment 3

[0030] (1) Weigh a certain amount of V 2 o 5 (molecular weight 181.88, analytically pure) put into distilled water and stir and heat to 80°C to prepare solution A, V 2 o 5 The mass ratio of oxalic acid to distilled water is 3:100; weigh a certain amount of oxalic acid and dissolve it in distilled water to make solution B, the mass ratio of oxalic acid to distilled water is 6:100, oxalic acid and V 2 o 5 The molar ratio is 3:1;

[0031] (2) Slowly add the above-mentioned solution B to the solution A, heat and stir the solution to 100°C, the solution turns blue and transparent, then continue to stir and keep warm for 1 hour to obtain the solution C;

[0032] (3) Weigh a certain amount of NaNO according to the V:Na molar ratio of 3:1.1 3 (Molecular weight 84.99, analytically pure) soluble in distilled water, NaNO 3 The mass ratio to distilled water is 1:50. After stirring for 10 minutes, the solution D is obtained, and the solution D is slowly added dropwise to the solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com