Combined method and device for deep dehydration of working solution in preparation of hydrogen peroxide by anthraquinone process

A hydrogen peroxide and deep dehydration technology, applied in the direction of peroxide/peroxy hydrate/peroxyacid/superoxide/ozonide, chemical instruments and methods, inorganic chemistry, etc., can solve the problem of not overcoming energy consumption, etc. problems, to achieve the effects of small footprint, height increase and decrease, and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

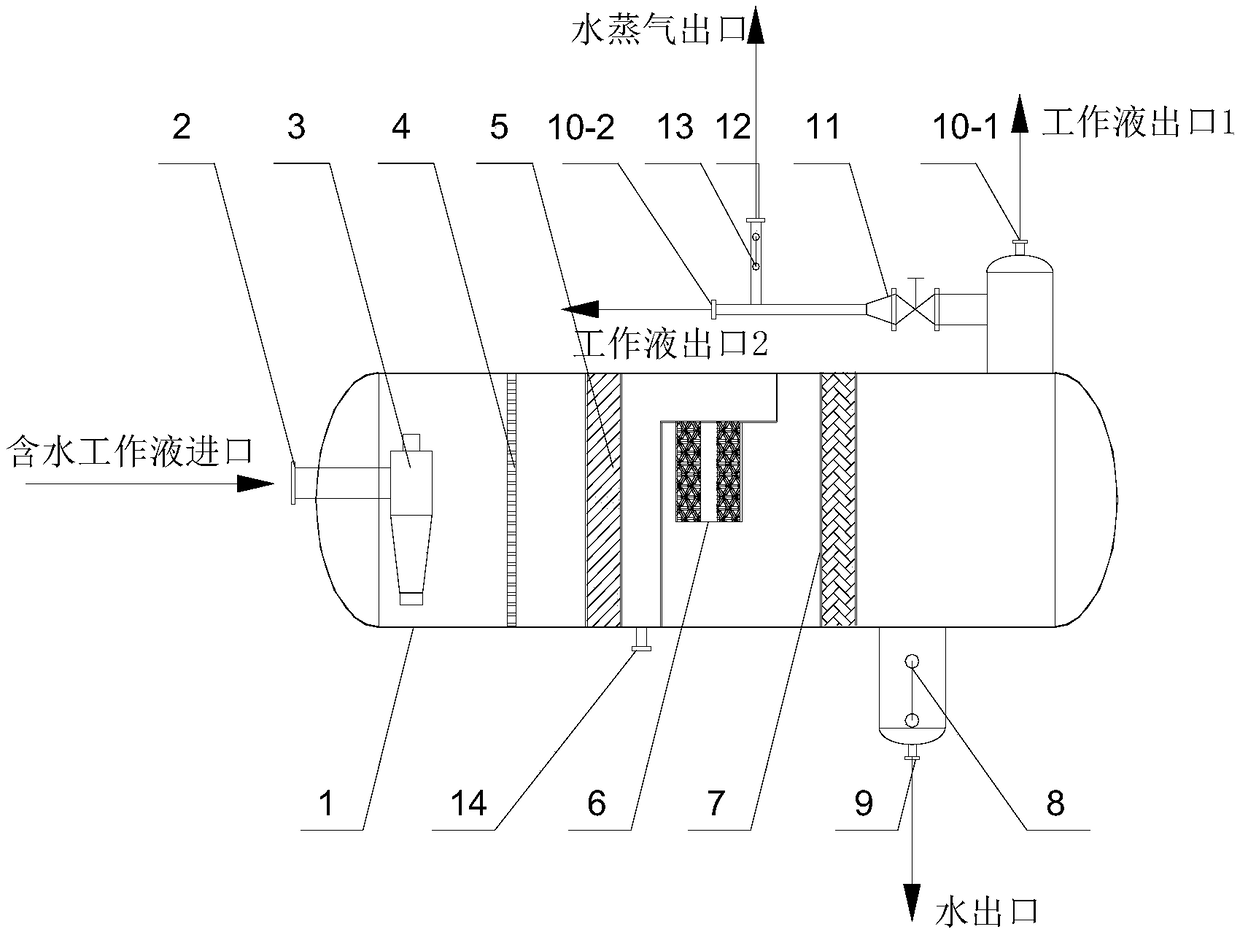

[0042]After extensive and in-depth research, the inventors of the present application found that the working liquid in the anthraquinone method for hydrogen peroxide is deeply dehydrated, and the traditional separation methods mainly include alkali tower dehydration method and vacuum dehydration method. However, both methods have many disadvantages. The dehydration treatment of hydrogen peroxide in the alkali tower will easily cause the working fluid to leave the drying tower with alkali. Once the alkaline substance enters the oxidation and extraction system, the hydrogen peroxide will be violently decomposed, and even explode. Danger. Due to the need for vacuuming during the vacuum dehydration process, the power consumption of the vacuum pump and its supporting chiller is relatively large, and the economy is poor. Moreover, if the size of the gas-liquid separation space is not appropriate, it is easy to cause liquid inclusion in the gas and increase the heat load of the conde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com