Metal bar polishing device

A metal rod and grinding machine technology, which is applied to metal processing equipment, grinding machines, grinding racks, etc., can solve the problems that the surface roughness of metal rods cannot meet the requirements, cannot automatically grind the top and bottom surfaces of metal rods, and cannot be controlled.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

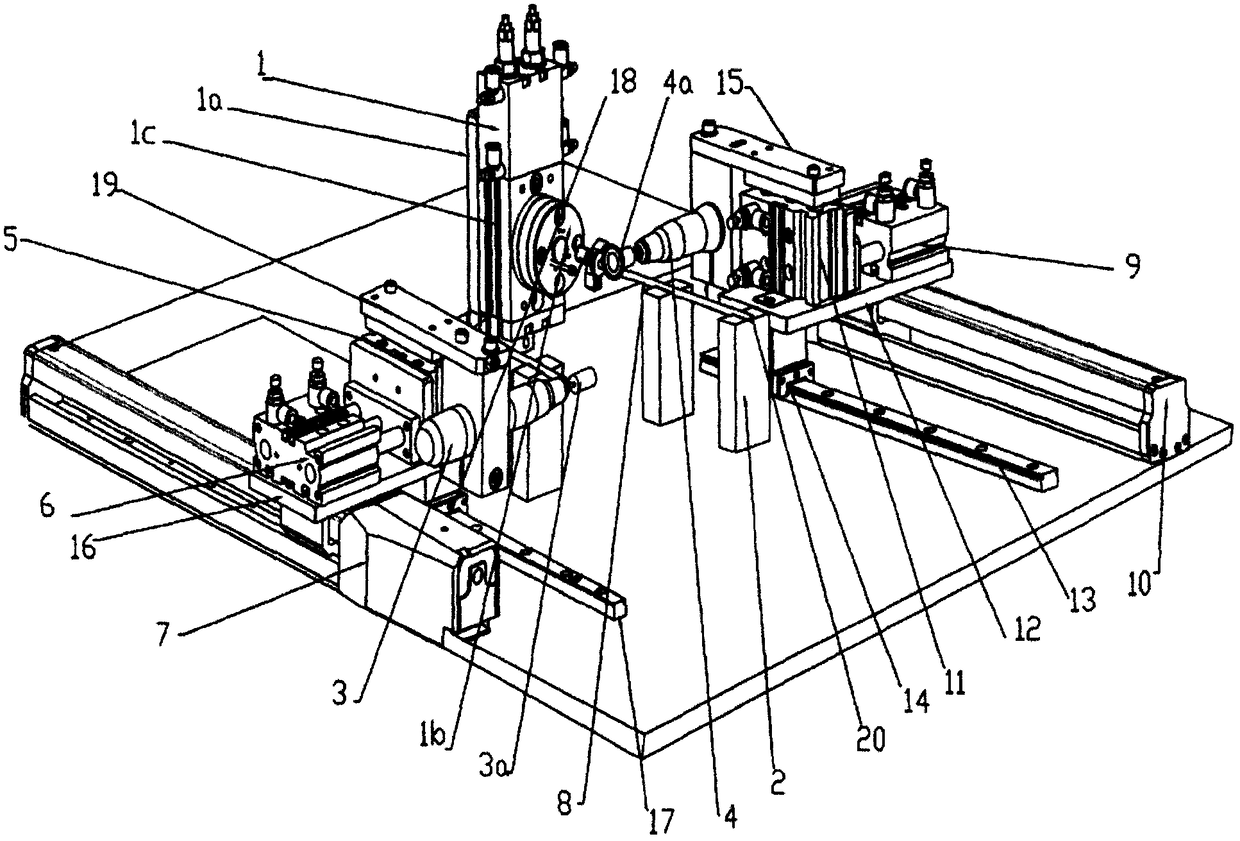

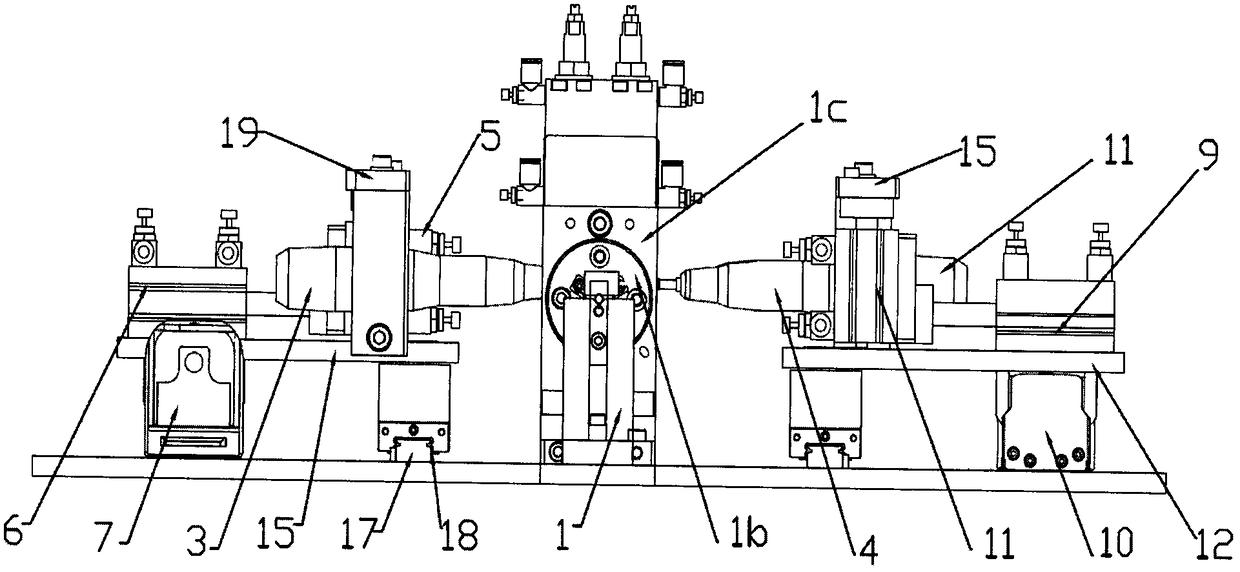

[0026] according to figure 1 as well as figure 2 The shown metal bar grinding device includes a metal bar clamping device 1, a metal bar fixing frame 2 arranged at the front end of the metal bar clamping device 1, a left grinding machine 3 located on the left side of the metal bar clamping device 1, and a The right grinder 4 on the right side of the metal rod clamping device 1; the metal rod clamping device 1 includes a mounting frame 1a, a pneumatic chuck 1b, and a 180-degree rotating cylinder 1c that drives the pneumatic chuck 1b to rotate on the mounting frame 1a , The pneumatic chuck 1b is composed of three chucks distributed at 120 degrees, and its oblique relative movement can clamp the metal rod. The output shaft of the 180-degree rotating cylinder 1c drives th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com