Supergravity preparation method for chitosan-supported nanoscale zero-valent iron and bimetal composite material thereof

A technology of nano-zero-valent iron and composite materials, applied in the field of nano-materials, can solve the problems of large process amplification effect, uneven particle size distribution, and poor reproducibility of batch production, and achieve low preparation cost, simple preparation method, and microscopic mixing and the effect of mass transfer process enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

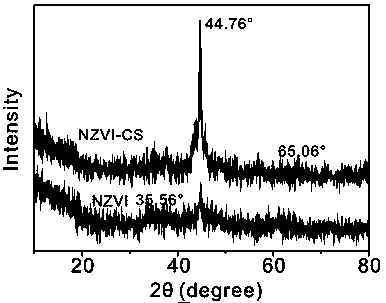

[0027] A high-gravity preparation method for chitosan-loaded nano-zero-valent iron and its bimetallic composite material. The mixed solution of chitosan and metal salt and the reducing agent are simultaneously sent into the high-gravity reactor for reaction. After the reaction, magnetic separation The reaction product is repeatedly washed with deionized water until neutral, and vacuum-dried to obtain chitosan-loaded nano-zero-valent iron and bimetallic composite particles, which specifically includes the following steps:

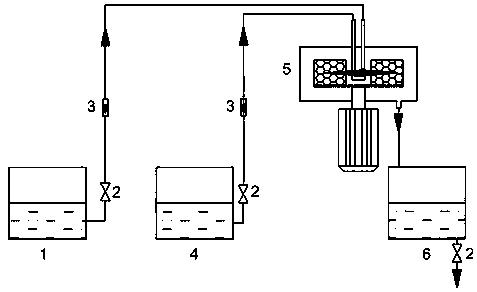

[0028] figure 1 It is the experimental flow chart of preparing chitosan-loaded nano-zero-valent iron particles with impinging flow-rotating packed bed as shown in this embodiment, and the specific steps are: take 5 g of chitosan and dissolve it in 1L 0.05mol / L A solution of chitosan with a concentration of 0.5% was prepared in an aqueous solution of nitric acid, and FeCl was added to it 2 • 4H 2 O (0.2 mol, 39.76 g) was prepared into an iron salt solution ...

Embodiment 2

[0031] A kind of supergravity preparation method of chitosan loaded nano-iron-copper bimetal composite particle, it comprises the following steps:

[0032] Weigh 1 g of chitosan and dissolve it in 1L of 0.05mol / L nitric acid aqueous solution to form an aqueous solution with a chitosan concentration of 0.1%, and add FeSO 4 •7H 2 O (0.04 mol, 11.12 g ) and CuCl 2 • 2H 2 O (0.01 mol, 1.70 g ) was configured into a solution with a metal ion concentration of 0.05 mol / L, in which Cu 2+ The mole fraction of the metal salt is 20%; in addition, according to BH 4 - and the molar ratio of metal ions is 3:1, weigh KBH 4 (0.15 mol, 8.09 g) was dissolved in 1L water to make KBH 4 Aqueous solution with a concentration of 0.15 mol / L; mix the above-mentioned chitosan and metal salt solution with KBH 4 The aqueous solution was added to the storage tank respectively, and the centrifugal pump was started to transport the two raw material liquids from the liquid distributor to the rotating...

Embodiment 3

[0034] A method for preparing chitosan-loaded nano-iron-nickel bimetal composite particles under high gravity, comprising the steps of:

[0035] Weigh 5 g of chitosan and dissolve it in 1L of 0.05mol / L nitric acid aqueous solution to prepare an aqueous solution with a chitosan concentration of 0.5%, and add Fe(NO 3 ) 2 (0.08 mol, 14.39 g) and NiCl 2 •6H 2 O (0.12 mol, 28.52 g) was prepared into a solution with a metal ion concentration of 0.2 mol / L, in which Ni 2+ The mole fraction of the metal salt is 60%; in addition, according to BH 4 - And the molar ratio of ferrous ion is 2.5:1, weigh NaBH 4 (0.5 mol, 18.92 g) was dissolved in 1L water to make NaBH 4 Aqueous solution with a concentration of 0.5 mol / L; mix the above-mentioned chitosan and metal salt mixed solution with NaBH 4 The aqueous solution is added to the storage tank respectively, and the centrifugal pump is started to transport the liquid into the impingement flow-rotary packed bed main device through the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com