Method for calculating four-way safety evaluation of well oil pipe head with crack defect

A calculation method and tubing head technology are applied in the field of safety assessment and calculation of structural parts of wellhead devices containing defects, which can solve the problems of limited application scope, safety check evaluation of structural parts that cannot bear pressure, insufficient accuracy and reliability, etc. The effect of improving the degree of fit and evaluating the results is safe and reasonable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

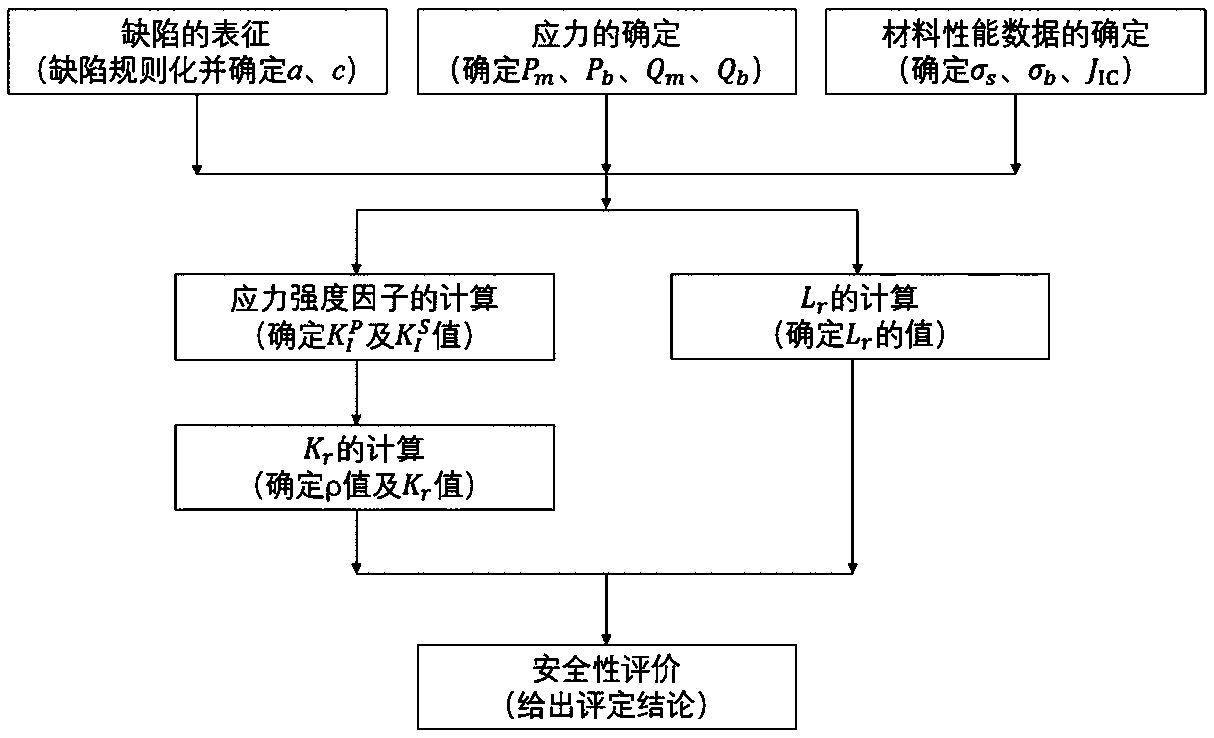

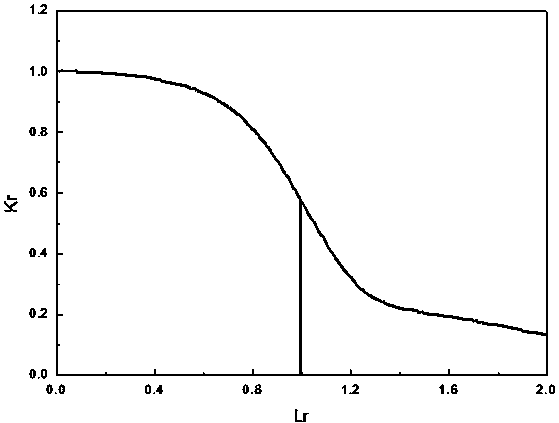

[0063] refer to Figure 3-Figure 7 , a method for calculating the safety assessment of a wellhead tubing head spool with crack defects, comprising the following steps:

[0064] (1) Determine the geometric dimensions of the oil pipe head spool, standardize the defects according to the actual position, shape and size of the crack, and obtain the corresponding characteristic crack size a, c, and the crack is equivalent to the major semi-axis c, short A semi-elliptical crack with semi-axis a.

[0065] (2) Determine the relevant material parameters of the tubing head, including: elastic modulus E, Poisson's ratio υ, yield strength σ s , tensile strength σ b , Fracture toughness J IC ;

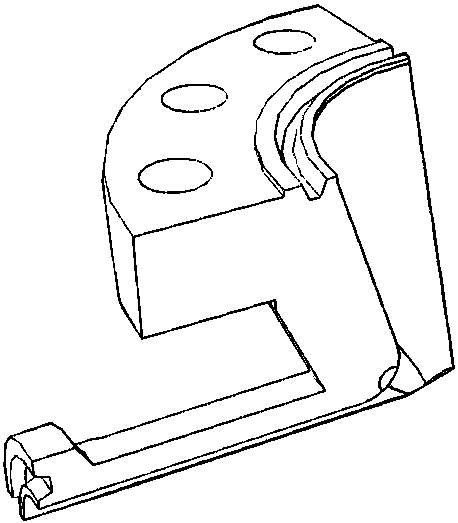

[0066] (3) Finite element simulation: use the finite element software ABAQUS to establish the finite element model of the tubing head spool; image 3 shown. Wherein, the first longitudinal plane D and the second longitudinal plane H extend along the Y direction, the transverse plane I extends ...

Embodiment 2

[0080] Others are the same as in Example 1, the difference lies in the corresponding stress intensity factor in step (6) K I Fracture toughness of materials used for evaluation K C After comparison, ifK I = K C , the critical size of the crack defect can be obtained, if K I ≠ K C , finite element modeling and re-preset crack defects.

[0081] The first longitudinal plane D and the second longitudinal plane H are longitudinal sections along the Y direction at the longitudinal outlet of the oil pipe head spool. The transverse plane I is the cross section along the X direction at the transverse outlet of the oil pipe head spool.

[0082] (1) For components with discontinuous local structures such as spools with oil pipe heads, the defect evaluation method in the standard "GB / T 19624-2004 Safety Evaluation of Pressure Vessels with Defects in Service" is not applicable to them. The present invention proposes A calculation method for evaluating the safety of a cracked t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com