Self-locking precast lining segment waterproof connector structure and working method thereof

A technology for lining segment and interface structure, which is applied in wellbore lining, tunnel lining, earth-moving drilling, etc., can solve the problems of high subway operation and maintenance cost, loose connection, seepage segment, etc., and achieve significant economic and social benefits. , to ensure stability and durability, to solve the effect of water seepage and leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited by the embodiments.

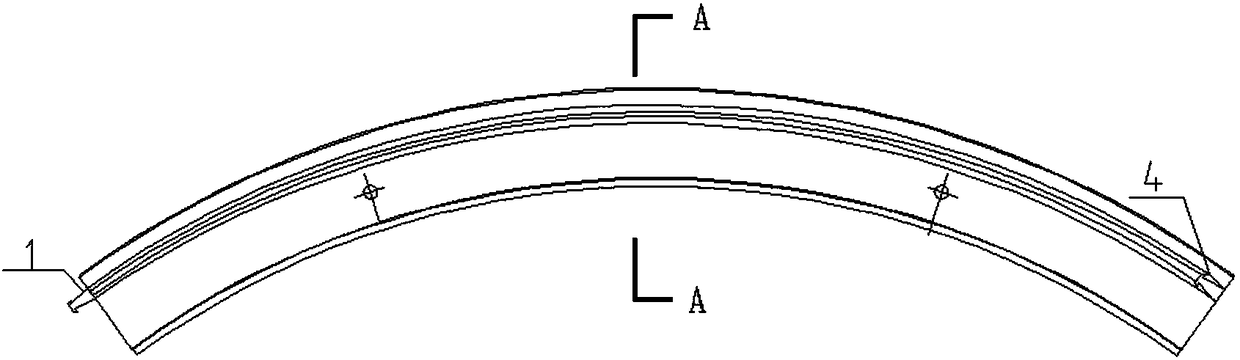

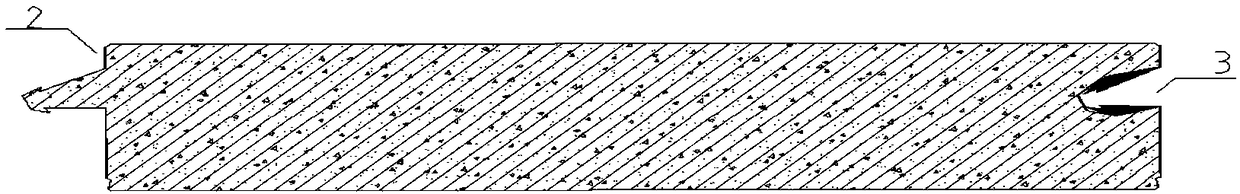

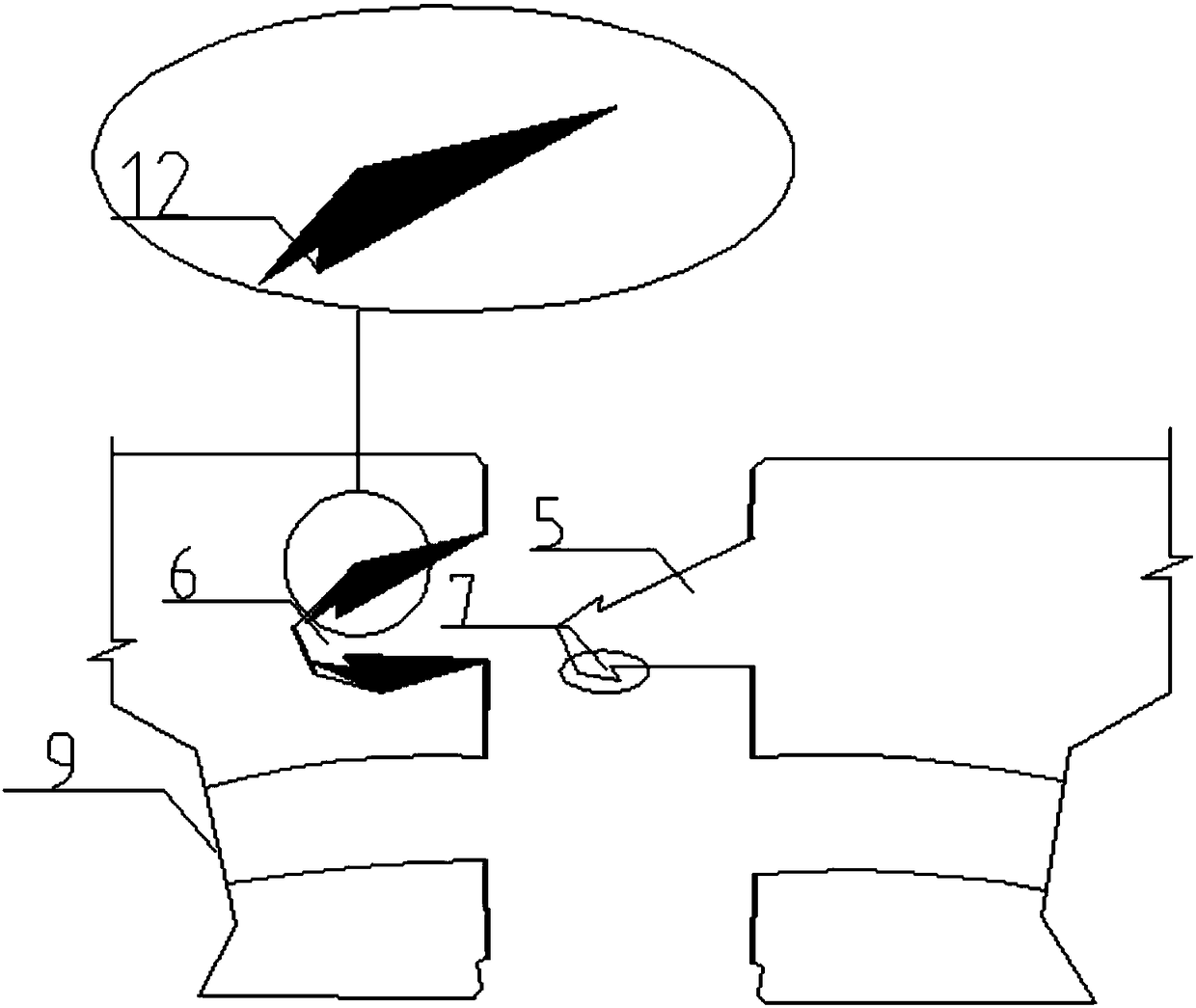

[0029] figure 1 It is the front view of the prefabricated lining segment containing the device of the present invention, figure 2 It is a schematic cross-sectional view of the prefabricated lining segment A-A containing the device of the present invention, image 3 It is the cross-sectional view of the present invention before splicing at the joint position containing bolts, Figure 4 It is a sectional view of the present invention spliced at the position of the joint with bolts and a detailed view of the self-locking device, Figure 5 It is the top view of the bolt self-locking device of the specific example mode of the present invention, Figure 6 It is the top view of the inner side of the single-ring lining of the embodiment of the present invention. As shown in the figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com