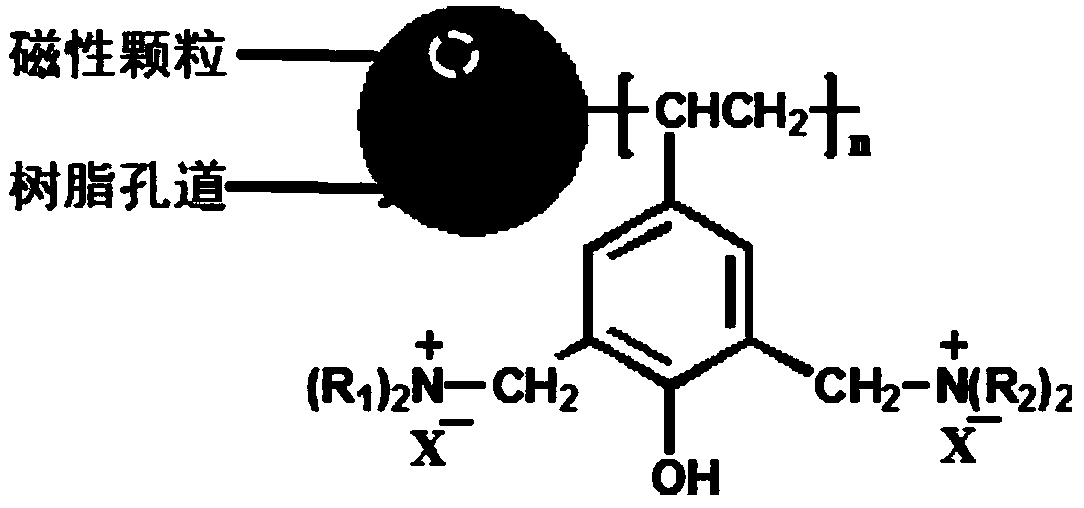

Hydrophilic magnetic strong base anion exchange micro-sphere resin and preparation method thereof

A styrene-based, anionic technology, applied in the field of resin materials, can solve problems such as poor hydrophilicity of styrene resins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

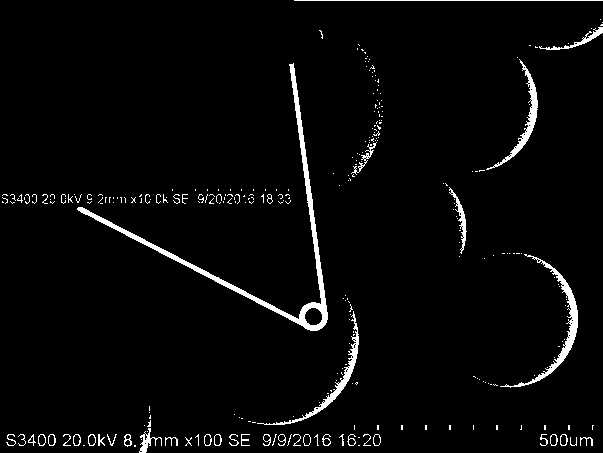

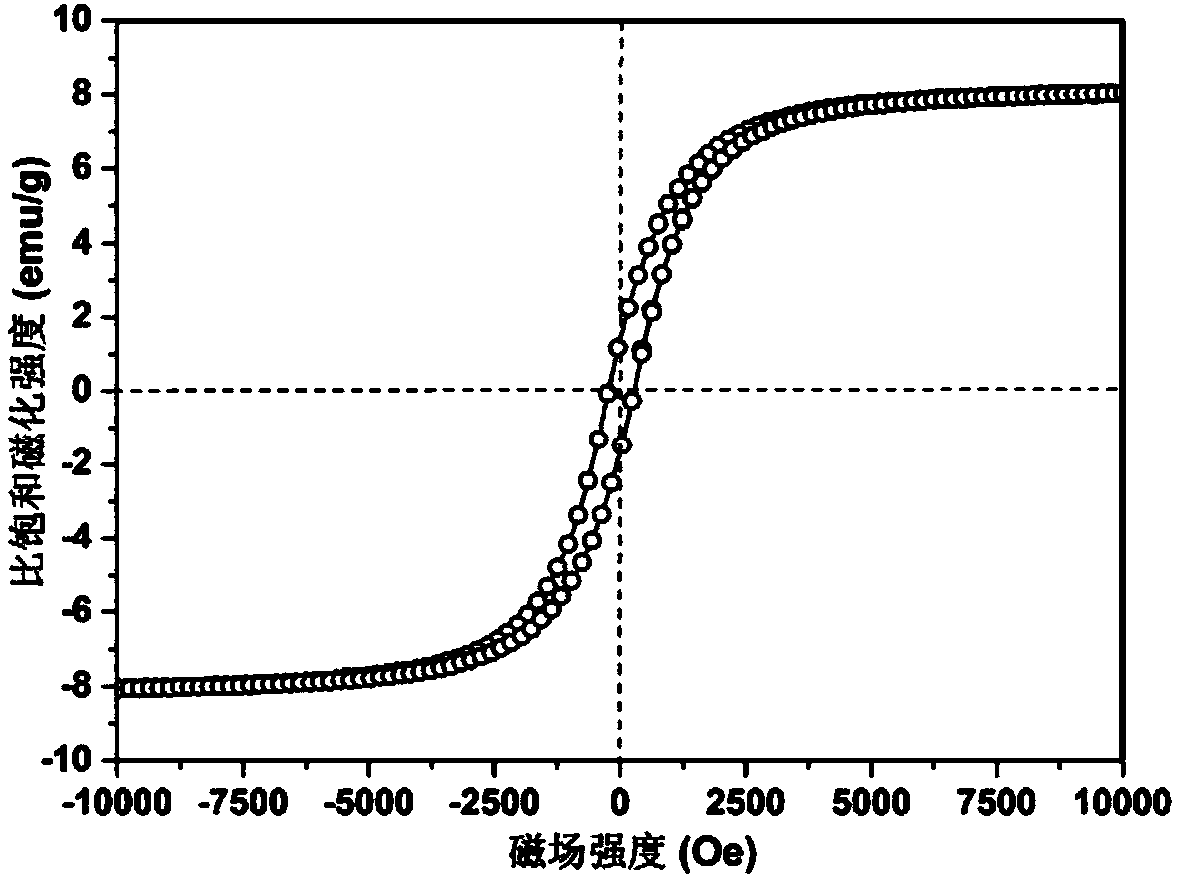

[0080] Weigh 20g Fe with a particle size of 8nm~300nm 3 O 4 With 80g 4-acetoxystyrene, 12.7g divinylbenzene, 7.3g ethylene glycol dimethacrylate, 0.6g azobisisobutyronitrile, 1.2g benzoyl peroxide, 30g cyclohexanol, 0.5g Mix isopropyl tris(dioctylphosphoryloxy) titanate coupling agent, stir well at 40°C for 45 minutes, and add to 500mL aqueous phase containing 0.5% hydroxyethyl cellulose and 5% sodium sulfate The solution was subjected to suspension polymerization in a 1L three-necked flask, and the stirring speed was controlled at 260rpm. Gradually raise the temperature to 80°C within 2h, keep it at this temperature for 8h, cool to room temperature, wash and dry with pure water and ethanol many times to obtain polyacetoxystyrene magnetic white balls. Add the polymerized white ball to 5 times the weight of 20% sodium hydroxide solution, stir and hydrolyze at 80°C for 4 hours, separate to obtain the resin ball, stabilize in the acidic solution of pH 3 to 4 for 2 hours, wash with...

Embodiment 2

[0084] Weigh 20g of α-Fe with a particle size of about 1μm 2 O 3 And γ-Fe 2 O 3 Mixture with 80g 4-acetoxystyrene, 12.7g divinylbenzene, 7.3g ethylene glycol dimethacrylate, 0.6g azobisisobutyronitrile, 1.2g benzoyl peroxide, 30g cyclohexanol, Mix 0.5g of vinyl trimethoxysilane coupling agent, stir well at 40°C for 45 minutes, add to 500mL aqueous solution containing 0.5% hydroxyethyl cellulose and 5% sodium sulfate, in a 1L three-necked flask For suspension polymerization, the stirring speed was controlled at 260 rpm. Gradually raise the temperature to 80°C within 2h, keep it at this temperature for 8h, cool to room temperature, wash and dry with pure water and ethanol many times to obtain polyacetoxystyrene magnetic white balls. Add the polymerized white ball to 5 times the weight of 20% sodium hydroxide solution, stir and hydrolyze at 80°C for 4 hours, separate to obtain the resin ball, stabilize in the acidic solution of pH 3 to 4 for 2 hours, wash with methanol and water a...

Embodiment 3

[0088] Weigh 20g of α-Fe with a particle size of about 1μm 2 O 3 And γ-Fe 2 O 3 Mixture with 80g 4-acetoxystyrene, 12.7g divinylbenzene, 7.3g allyl itaconic acid, 0.6g azobisisobutyronitrile, 1.2g benzoyl peroxide, 70g toluene, 0.3g isopropyl Dioleic acid acyloxy (dioctylphosphoryloxy) titanate coupling agent is mixed, fully stirred at 40 ℃ for 45 minutes, added to 500mL containing 0.5% hydroxyethyl cellulose, 5% sodium sulfate Suspension polymerization reaction was carried out in a 1L three-necked flask, and the stirring speed was controlled at 260rpm. Gradually raise the temperature to 80°C within 2h, keep it at this temperature for 8h, cool to room temperature, wash and dry with pure water and ethanol many times to obtain polyacetoxystyrene magnetic white balls. The dipolymerized white ball was added to 4 times the weight of 10% sodium hydroxide solution, stirred and hydrolyzed at 80°C for 6 hours, separated to obtain the resin ball, stabilized in the acid solution of pH 3 t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com