Carbon and silicon separation technology of nascent polysilicon and use device of technology

A polycrystalline silicon carbon and polycrystalline silicon technology, applied in the direction of silicon, electrolysis process, electrolysis components, etc., can solve the problems of high mechanical requirements, high energy consumption, inability to large-scale industrial application, etc., and achieve the effect of reducing corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

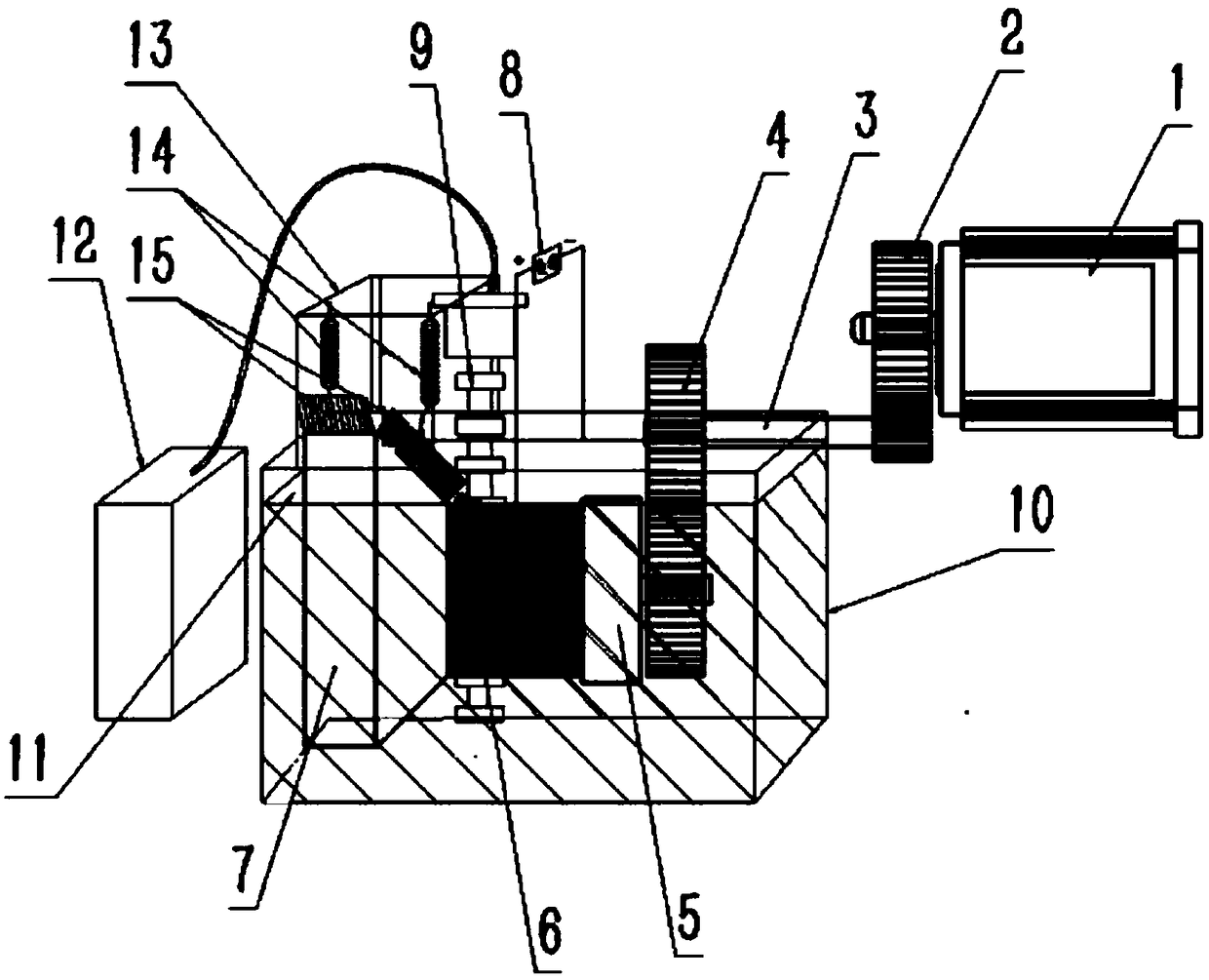

[0025] Such as figure 1 Shown: the present invention includes 1 motor, 2 first gear sets, 3 shaft couplings, 4 second gear sets, 5 fixtures, 6 graphite chucks, 7 primary polysilicon materials, 8 DC power supplies, 9 ultrasonic vibrating rods, and 10 graphite reaction pool, 11 concentrations of 15-25% sodium hydroxide solution, 12 ultrasonic vibrating rod power supply, 13 brackets, 14 springs and 15 brushes.

[0026] In the present invention, 1 motor is connected to 2 first gear sets, 2 first gear sets are connected to 4 second gear sets through 3 coupling shafts, 5 is connected to 4 second gear sets by the shaft on the clamp, 5 clamps are clamped on 6 graphite chucks, When the 1st motor drives the 2nd gear set to rotate, the 4th second gear set is driven by the 3 coupling, and the 4th second gear set drives the 5 fixture and the carbon fiber which is composed of 6 graphite chucks and 7 primary polysilicon materials connected to it. The head material rotates at a certain speed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com