Hot isostatic pressing method for preventing adhesion between welding part and package sleeve.

A technology of hot isostatic pressing and welding parts, which is applied in welding equipment, non-electric welding equipment, ion implantation plating, etc., can solve the problems of incomplete anti-adhesion effect and welding interface defects, and achieve the integrity of weldments, easy separation, The effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

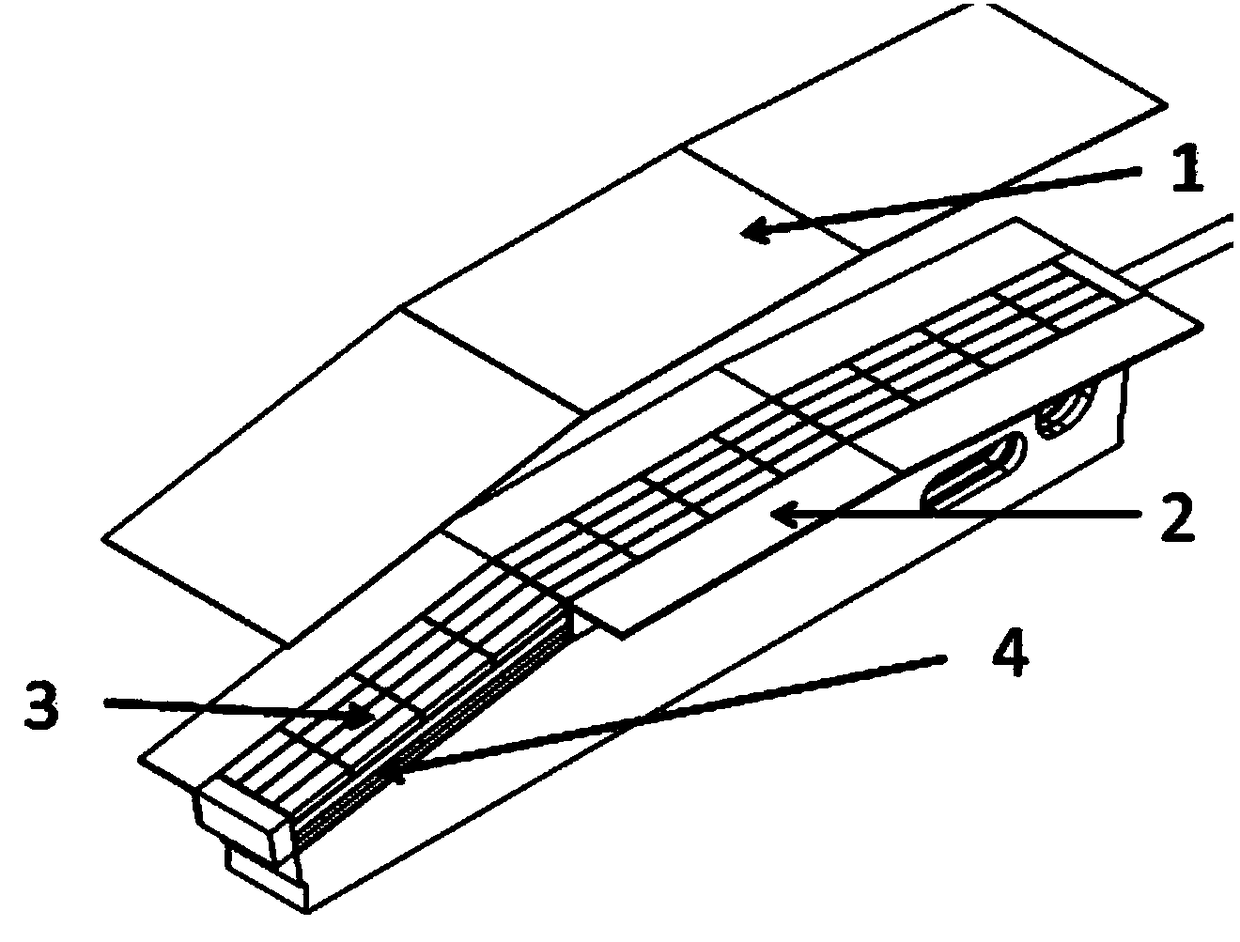

[0045] The part to be welded is the semi-prototype finger module of the first wall of the shielding cladding of the thermonuclear experimental reactor, such as figure 1 As shown, the finger module is composed of 48 beryllium tiles 3 of different sizes and a curved composite plate cooling base 4 with cooling channels through hot isostatic welding. The curved surface composite plate cooling base 4 is made of copper-chromium-zirconium alloy or 316L stainless steel or 316N stainless steel.

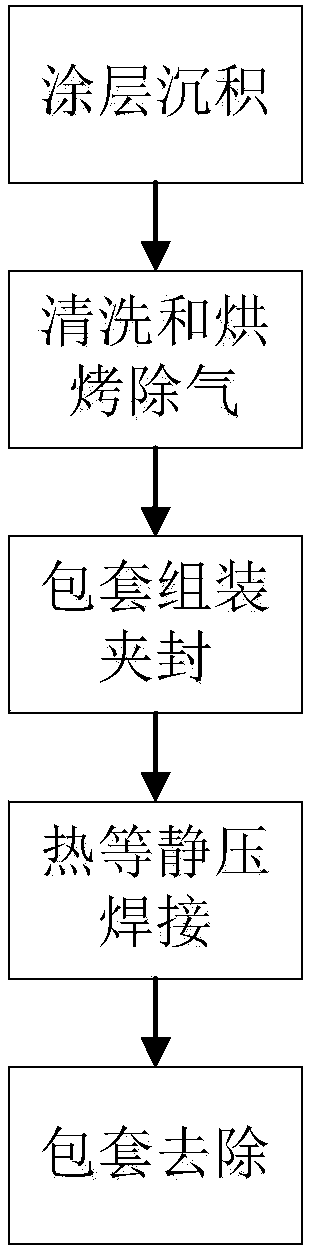

[0046] The hot isostatic pressing method in the present embodiment is as figure 2 As shown, it specifically includes the following steps:

[0047] Step 1. Coating Deposition

[0048] Depositing a ceramic-based coating on the part of the surface of the sheath cover 1 in contact with the beryllium tile 3;

[0049] The jacket cover 1 is made of 304 stainless steel with a thickness of 2 mm, and an alumina ceramic coating is deposited on the part of its surface in contact with the beryllium til...

Embodiment 2

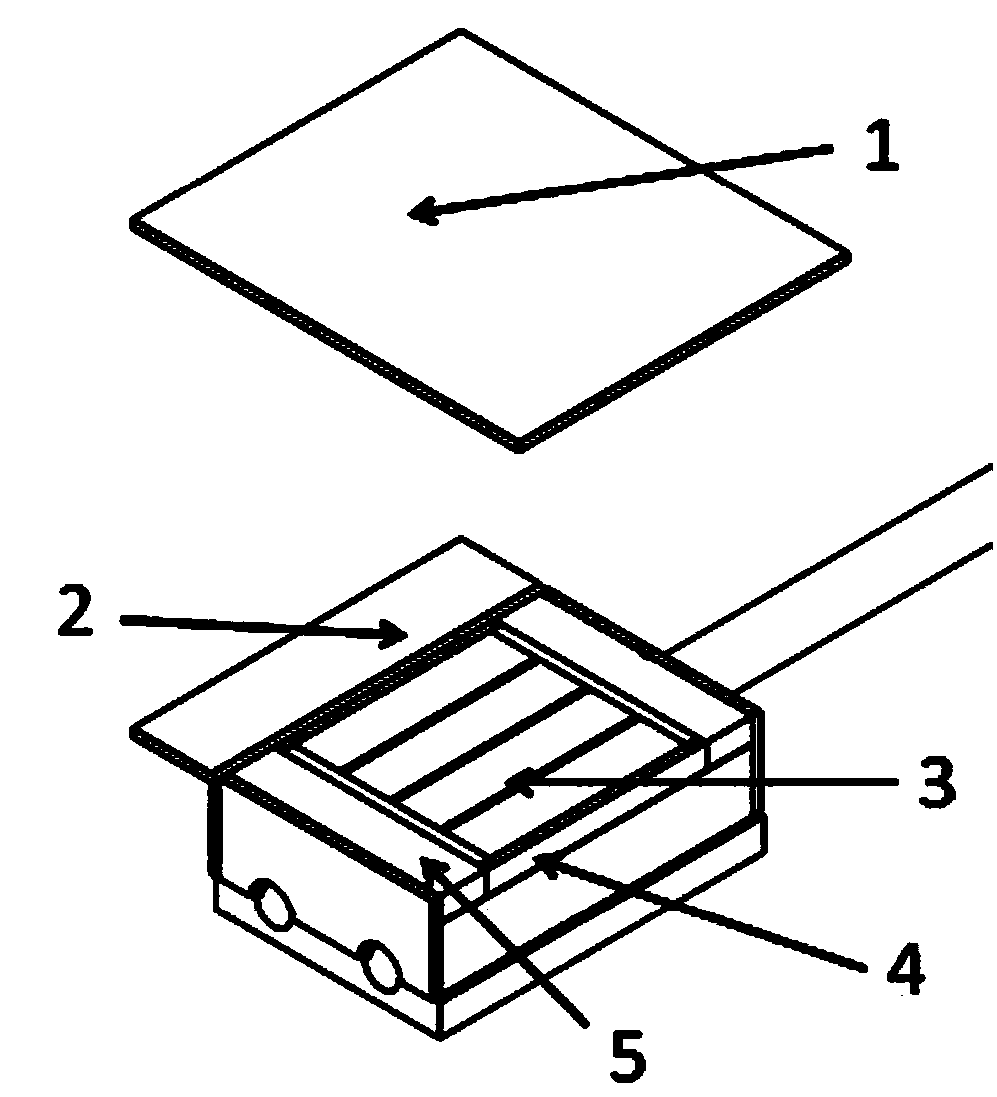

[0068] The part to be welded is the neutron irradiation module of the first wall of the shielding cladding of the thermonuclear fusion experimental reactor, such as figure 2 As shown, the neutron irradiation module is composed of four beryllium tiles 3 and a curved composite plate cooling base 4 with cooling channels through hot isostatic welding. The curved surface composite plate cooling base 4 is made of copper-chromium-zirconium alloy or 316L stainless steel or 316N stainless steel.

[0069] The method used in this embodiment specifically includes the following steps:

[0070] Step 1. Coating Deposition

[0071] Depositing a carbon-based coating on the part of the surface of the sheath cover 1 in contact with the beryllium tile 3;

[0072] The wrapping cover 1 is made of 304 stainless steel with a thickness of 2 mm, and a carbon-based coating is deposited on the part of its surface that is in contact with the beryllium tile 3 by means of a magnetic filter cathode arc. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com