Bi-component addition type mold silicone rubber for injection molding

An injection molding, two-component technology, applied in the field of mold silicone rubber, can solve the problems of uneven damage, bottom penetration, irregular size, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

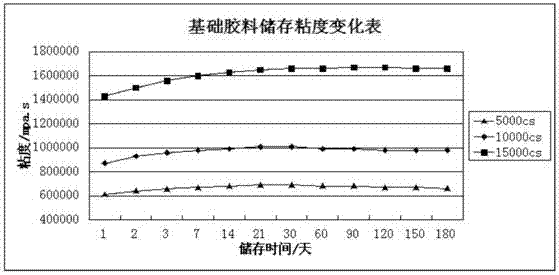

[0025] 1. Preparation of base rubber with viscosity 5000cs vinyl silicone oil as the main oil

[0026] 100 parts by mass of aA200 fumed silica, 140 parts by mass of vinyl silicone oil with a viscosity of 5000cs (about 0.23% vinyl content), 15 parts by mass of hexamethyldisilazane, and 15 parts by mass of vinyltriethoxysilane 2 parts by mass and 2 parts by mass of distilled water were kneaded in a kneader for 2 hours, and the temperature was kept below 120°C during the kneading process;

[0027] b. Under the stirring state of the kneader, the temperature of the material is raised to 150°C, kneaded and dried under vacuum for 3 hours, during which the temperature gradually rises to 176°C;

[0028] c Add 85 parts by mass of 5000cs vinyl silicone oil, 15 parts by mass of methyl polysiloxane with a viscosity of 500cs, and continue kneading, heat the mixed rubber to 130°C, knead and dry under vacuum for 1 hour;

[0029] d. Discharging, the obtained material is ground on a three-roll...

Embodiment 2

[0037] 1. Preparation of base rubber with viscosity 10000cs vinyl silicone oil as the main oil

[0038] a 100 parts by mass of A380 fumed silica, 100 parts by mass of vinyl silicone oil (vinyl content about 0.19%) with a viscosity of 10000cs, 25 parts by mass of hexamethyldisilazane, vinyltriethoxysilane 3 parts by mass and 2.5 parts by mass of distilled water were kneaded in a kneader for 3 hours, and the temperature was kept below 120°C during the kneading process;

[0039] b. Add 4 parts by mass of distilled water into the kneader and knead for 1.5 hours below 120°C;

[0040] c. Under the stirring state of the kneader, the temperature of the material is raised to 160° C., and vacuum kneaded and dried for 3 hours;

[0041] d Add 130 parts by mass of 10000cs vinyl silicone oil, 20 parts by mass of methyl polysiloxane with a viscosity of 500cs) and continue kneading, heat the mixed rubber to 150°C, knead and dry in vacuum for 2 hours;

[0042] e discharge, the resulting mate...

Embodiment 3

[0050] 1. Preparation of base rubber with viscosity 15000cs vinyl silicone oil as the main oil

[0051]a 100 parts by mass of A380 fumed silica, 80 parts by mass of vinyl silicone oil with a viscosity of 15000cs (vinyl content about 0.14%), 30 parts by mass of hexamethyldisilazane, vinyltriethoxysilane 5 parts by mass and 3 parts by mass of distilled water were kneaded in a kneader for 4 hours, and the temperature was kept below 120°C during the kneading process;

[0052] b. Add 6 parts by mass of distilled water into the kneader and knead for 2 hours below 120°C;

[0053] c. Under the stirring state of the kneader, the temperature of the material is raised to 180° C., and vacuum kneaded and dried for 3 hours;

[0054] d Add 155 mass parts of 15000cs vinyl silicone oil, 25 mass parts of methyl polysiloxane with a viscosity of 500cs) and continue kneading, the mixed rubber material is heated up to 180°C, vacuum kneaded and dried for 2 hours;

[0055] e discharge, the resultin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com