Laser assisted machining system and workpiece preheating device thereof

A processing system and laser-assisted technology, applied in optical components, optics, instruments, etc., can solve problems affecting workpiece processing efficiency and quality, material variation, etc., and achieve the effect of reducing equipment construction costs and improving processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

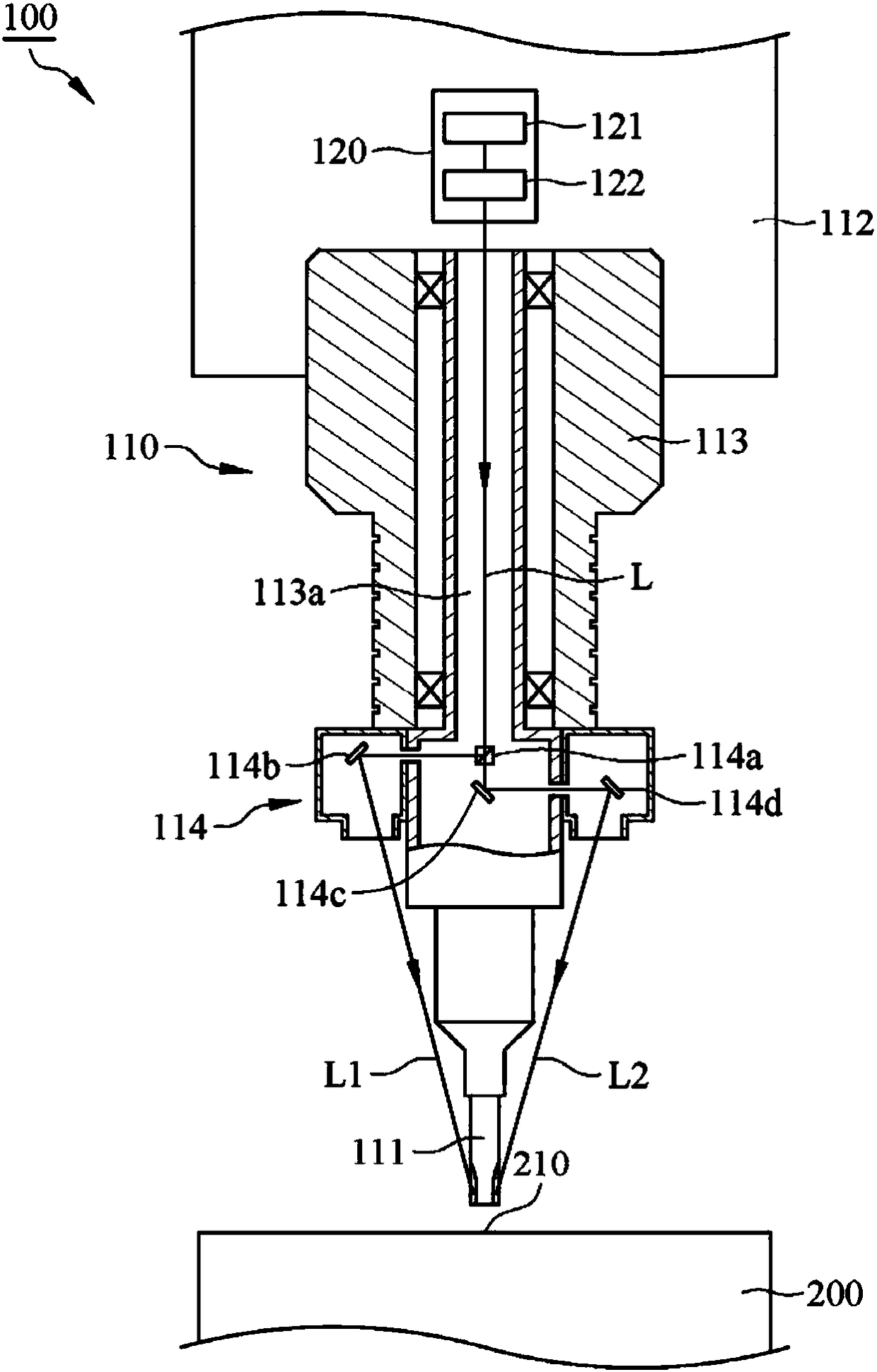

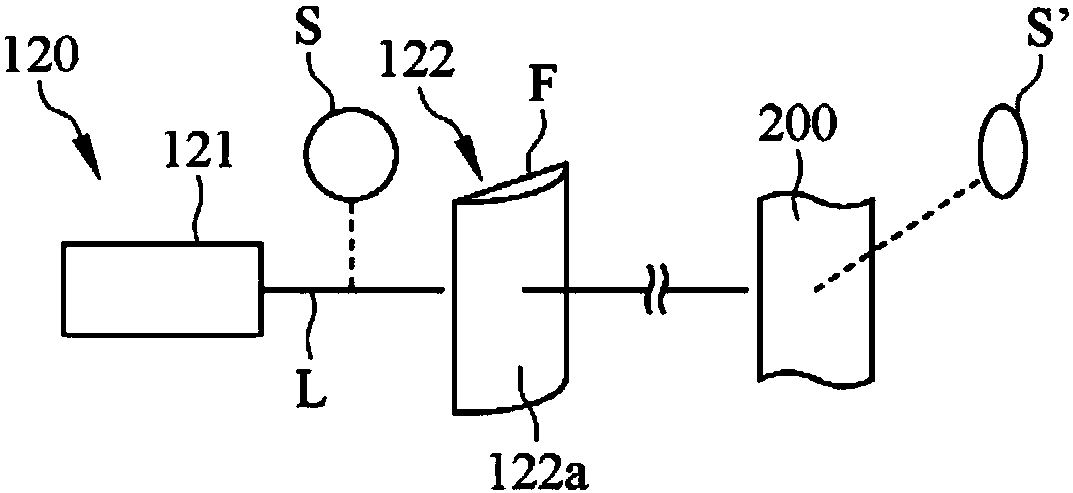

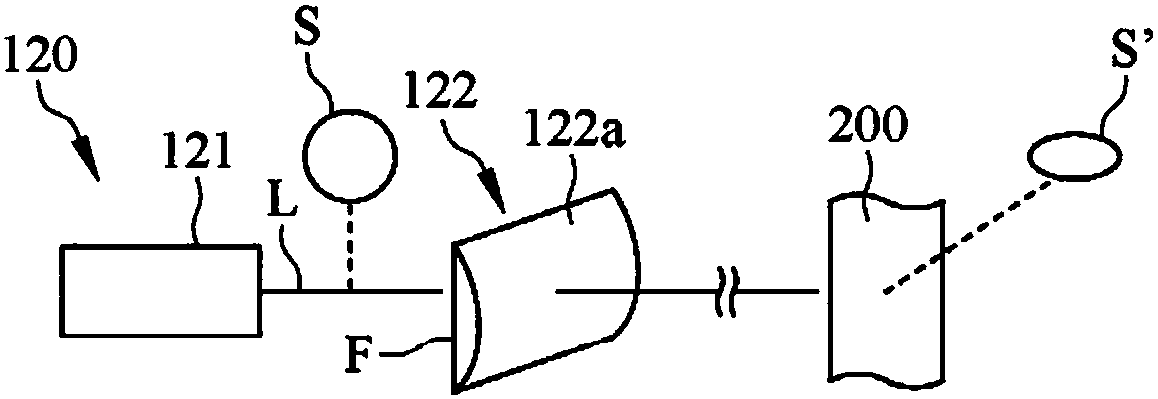

[0033] see figure 1 , a laser-assisted processing system 100 of the present invention includes a processing tool 110 and a workpiece preheating device 120, the processing tool 110 has a tool 111, and the tool 111 is used for processing (such as turning or milling) in the area 210 to be processed of the workpiece 200 processing), the workpiece preheating device 120 has a laser source 121 and a modulating mirror group 122, the laser source 121 is used to emit a laser beam L to the modulating mirror group 122, and the laser beam L passes through the modulating mirror group 122 ( That is, the modulating mirror group 122 is arranged on the optical path of the laser beam L), and the modulating mirror group 122 is used for modulating the laser light shape S of the laser beam L, so as to focus and form the laser spot S' on the workpiece 200 This area to be processed 210 (see Figure 2a to Figure 2d and Figure 3a to Figure 3d ), the laser spot S' is used to preheat and soften the ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com