Surface sand-blasting forming device for cloth

A technology of surface sandblasting and cloth, applied in the direction of fabric surface trimming, textile and papermaking, thorn pattern, etc., can solve the problems of complex structure, low economic benefit and high cost of thermal transfer printing machine, achieve simple structure, improve economic benefits, The effect of reducing the consumption of costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

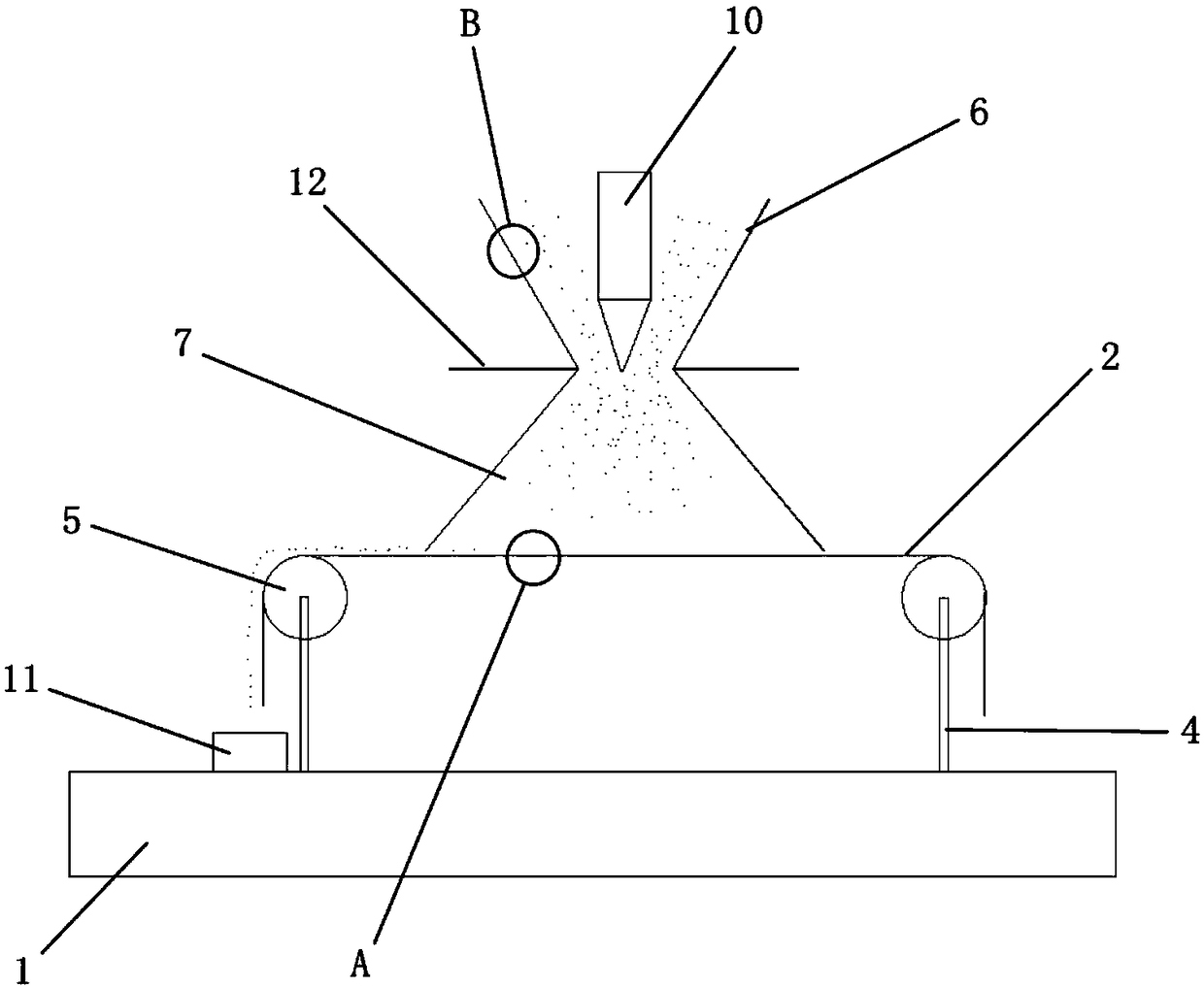

[0024] The present invention will now be further described in detail in conjunction with the accompanying drawings and embodiments. These drawings are all simplified schematic diagrams, only illustrating the basic structure of the present invention in a schematic manner, so it only shows the composition related to the present invention.

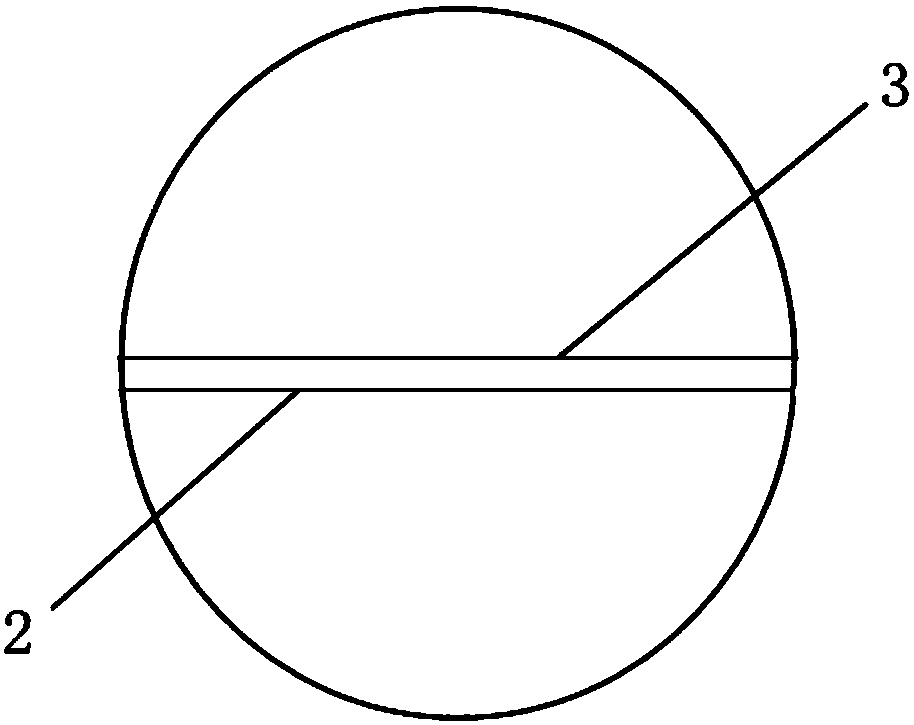

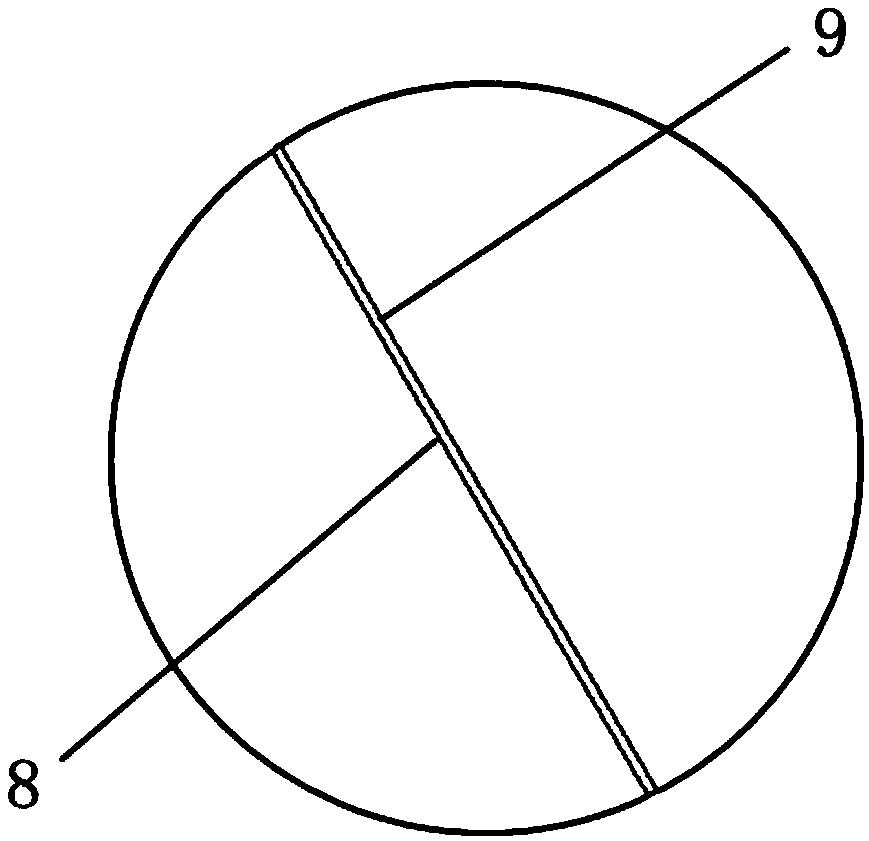

[0025] Such as figure 1 , figure 2 with image 3 As shown, a cloth surface sandblasting forming device includes a base 1, a cloth 2 and a hopper; the cloth 2 moves through a transmission roller 5, and the transmission roller 5 converts its own rotation into a linear motion of the cloth 2, The surface of the cloth 2 is provided with a forming diaphragm 3, and the cloth 2 forms a specific pattern according to the shape of the forming diaphragm 3 during the sandblasting operation. 2 to form a corresponding pattern, and the forming diaphragm 3 can be replaced, so that the filter cloth 2 can be formed with a corresponding pattern by replacing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com