Preparation for high-activity iron nitrogen carbon catalyst by adopting middle-temperature carbonized metal framework compound pore expanding technology

A technology of iron-nitrogen-carbon catalyst and skeleton compound, which is applied in the field of electrocatalysis, can solve the problems of lack of a clear understanding of coordination changes and structural evolution, and achieve the effects of large-scale production, simple process, and abundant raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

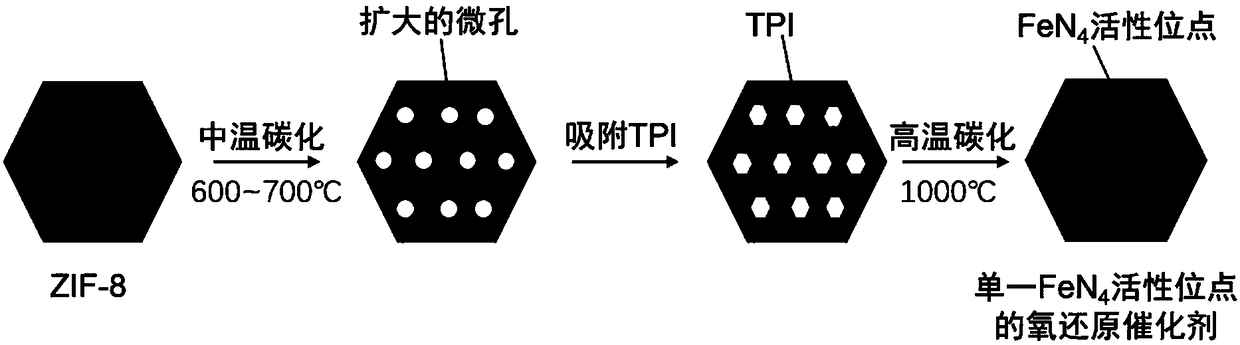

[0033] Medium-temperature carbide metal skeleton compound pore expansion technology is used in the preparation of high-activity iron-nitrogen-carbon catalysts. The schematic diagram of the preparation method is as follows figure 1 As shown, it is a three-step strategy of "hole expansion-filling-pyrolysis", and the specific steps are as follows:

[0034] In the first step, 1.47g of Zn(NO 3 ) 2 ·6H 2 O and 1.63 g of 2-methylimidazole were dissolved in 100 ml of anhydrous methanol, stirred at room temperature for 10 h, centrifuged, washed, and dried to obtain ZIF-8 nanoparticles.

[0035] The second step, medium-temperature carbonization: ZIF-8 nanoparticles were ground and placed in a quartz boat, and kept in an argon atmosphere at 650° C. for 1 hour in a tube furnace to obtain medium-temperature carbonized ZIF-8 nanoparticles.

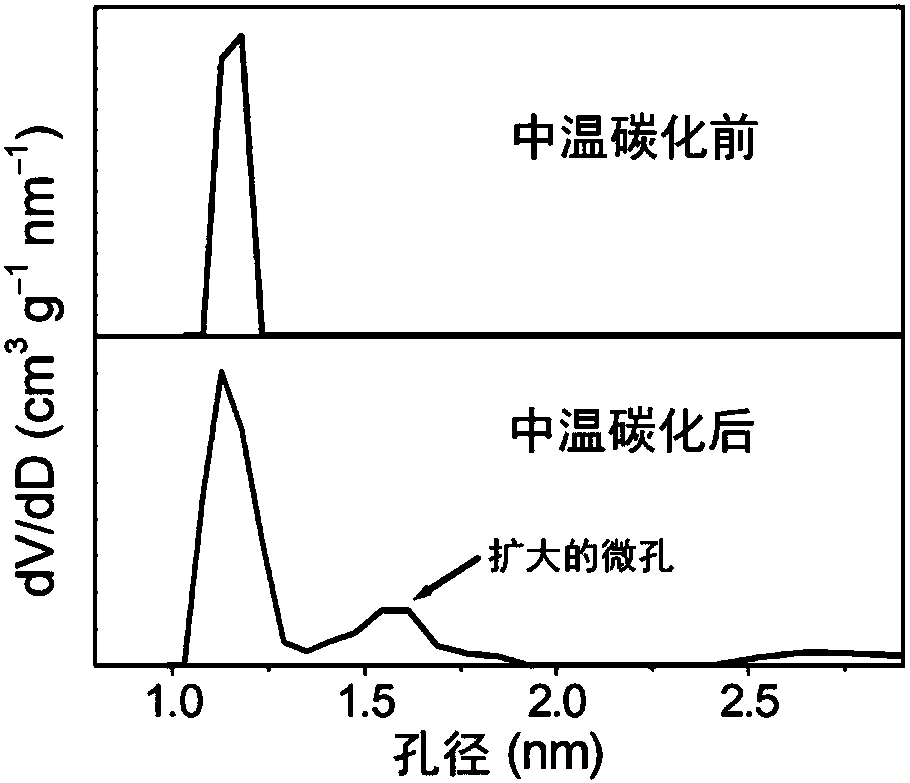

[0036] The pore diameter of ZIF-8 nanoparticles after medium-temperature thermal carbonization is expanded from 1.16 nanometers to 1.3-1.8 nanometer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum power density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com