Radial oxygen production adsorption tower

An adsorption tower and tower body technology, applied in oxygen preparation, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of uneven adsorption, small height-diameter ratio of adsorption towers, large floor space, etc. Improve the adsorption effect, the effect of uniform intake pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

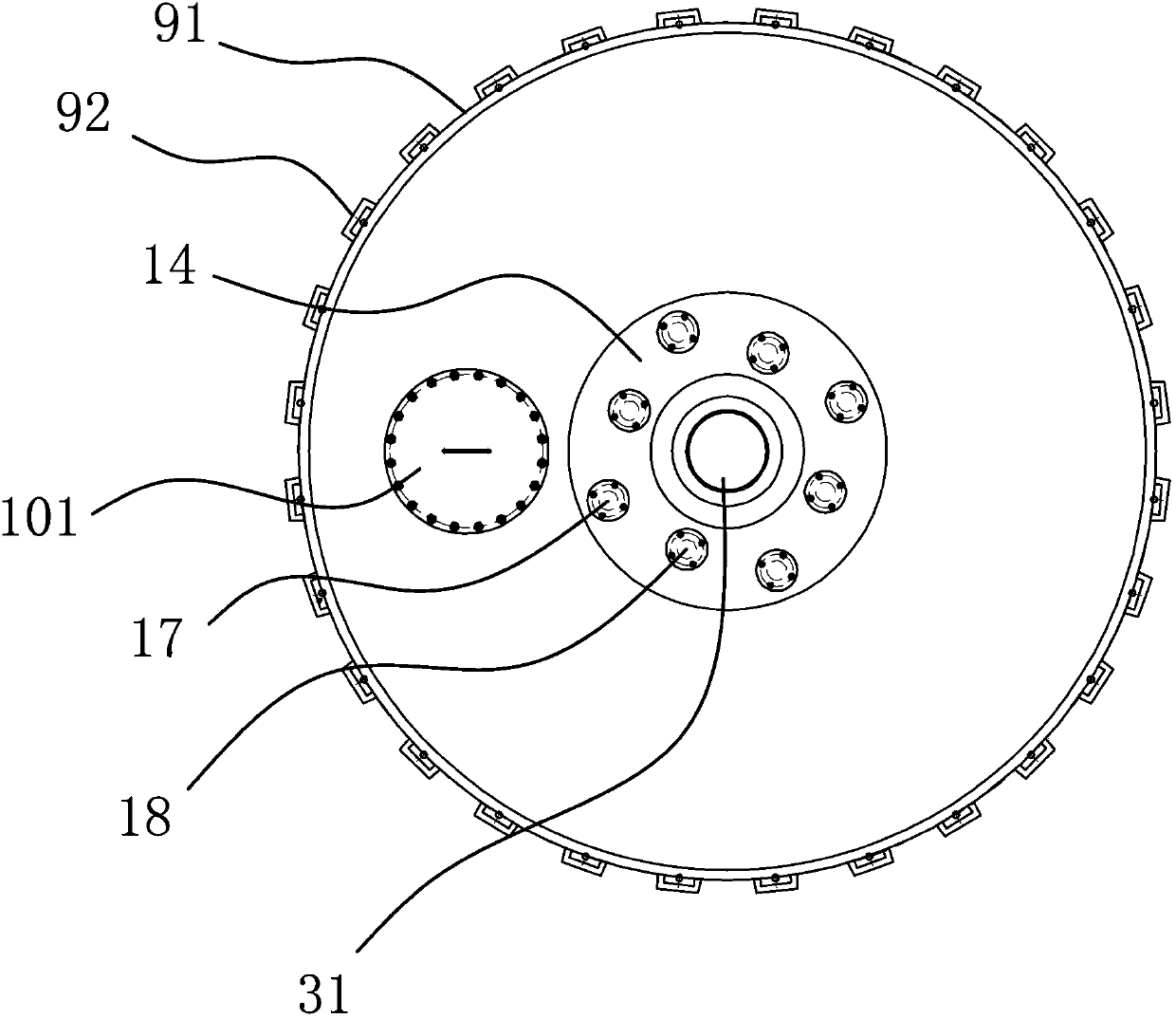

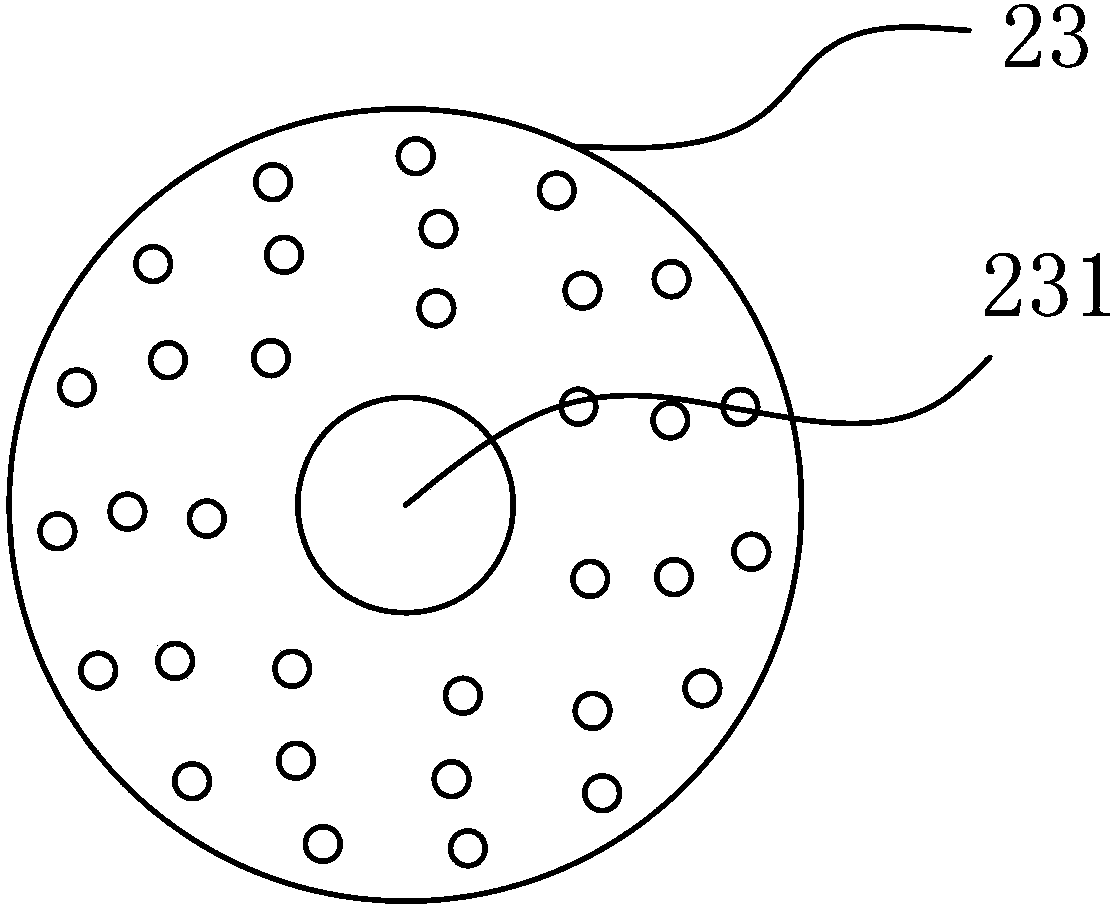

[0031] like figure 1 As shown, a radial oxygen-making adsorption tower includes a cylindrical tower body 9, an air intake assembly 2 is provided at the bottom of the tower body 9, and an air outlet assembly 3 is provided at the top, and the tower body 9 is provided with an adsorption Component 1, an annular air delivery chamber 4 is formed between the inner wall of the tower body 9 and the outer wall of the adsorption component 1, the air intake component 1 has an annular vent 10 located on the periphery of the lower end of the adsorption component 1, and the annular The air vent 10 communicates with the air delivery chamber 4, and the air delivery chamber 4 can transport the air flow radially to the adsorption assembly 1. The two ends of the adsorption assembly 1 are closed and there is a gas collector in the center of the adsorption assembly 1 for collecting the oxygen of the finished product. The channel 5, the lower end of the air-collecting channel 5 is closed, and the up...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com