Manufacturing method of waterproof braided fabric

A manufacturing method and technology of waterproof fabrics, which are applied in textile and papermaking, fiber processing, ultrasonic/sonic fiber processing, etc., can solve the problems of softness not meeting requirements, textiles are not soft enough, etc., and improve surface adhesion, The effect of changing surface wettability and improving softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

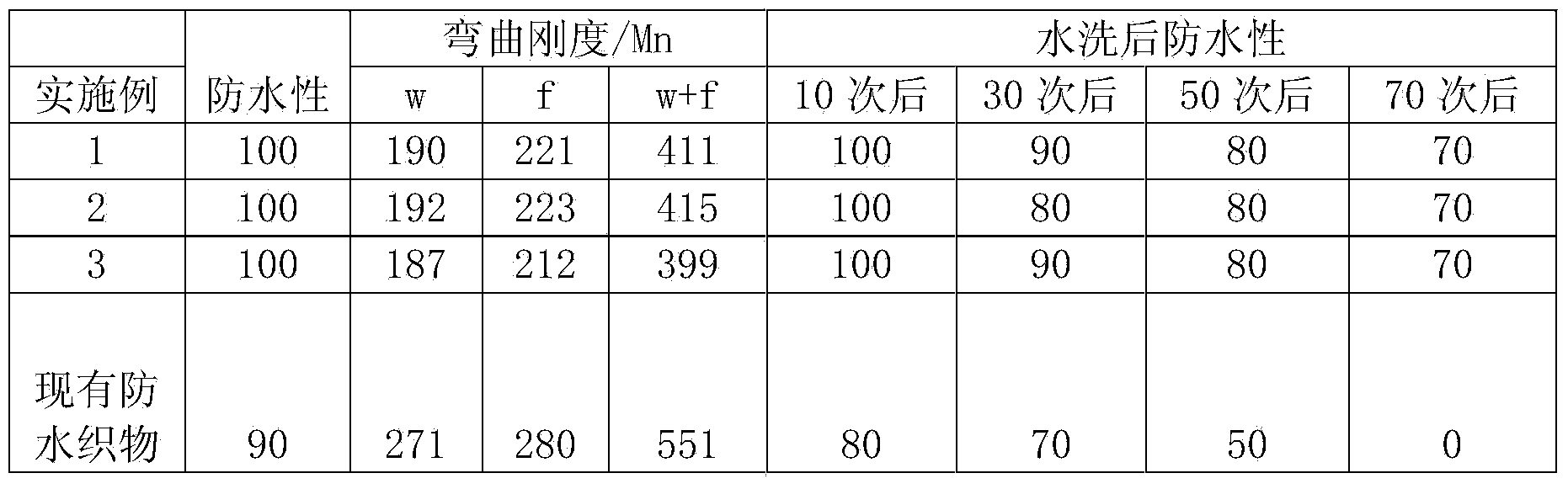

Examples

Embodiment 1

[0018] A manufacturing method of waterproof fabric includes the following steps:

[0019] (1). Treat the dyed and dried cotton cloth in a constant temperature and humidity box at 20°C and 70RH for 3 hours, then perform corona treatment, and treat it under 6kV for 7 seconds;

[0020] (2) After the corona treated textile is immersed with amino silicone waterproofing agent for 2s, it is double-dipped and double-rolled, with a surplus rate of 60%, and dried at 100°C for 4 minutes to obtain a soft and waterproof textile.

[0021] The preparation method of the amino organosilicon waterproof treatment agent is:

[0022] a. 0.3mol of octamethylcyclotetrasiloxane and 1mol of tetravinyltetramethoxycyclotetrasiloxane are distilled under reduced pressure under the condition of 0.75MPa to remove low boiling substances, and then 1mol of N-β is added -(Aminoethyl)-γ-aminopropylmethyldimethoxysilane and 0.001mol potassium hydroxide, reacted at 130℃ for 10h under normal pressure, then heated to 160℃, ...

Embodiment 2

[0025] A manufacturing method of waterproof fabric includes the following steps:

[0026] (1) Treat the dyed and dried polyester in a constant temperature and humidity box at 25°C and 60RH for 4 hours, and then perform corona treatment and treat it under 9kV for 3 seconds;

[0027] (2) After the corona treated textile is immersed with amino silicone waterproofing agent for 3 seconds, it is double-dipped and double-rolled, with a surplus rate of 65%, and dried at 120°C for 2 minutes to obtain a soft and waterproof textile.

[0028] The preparation method of the amino organosilicon waterproof treatment agent is:

[0029] a. 0.3mol of octamethylcyclotetrasiloxane and 1mol of tetravinyltetramethoxycyclotetrasiloxane were distilled under reduced pressure under the condition of 0.75MPa to remove low boiling substances, and then 2molN-β was added -(Aminoethyl)-γ-aminopropylmethyldimethoxysilane and 0.003mol potassium hydroxide, reacted at 150℃ for 7h under normal pressure, then heated to 160...

Embodiment 3

[0032] A manufacturing method of waterproof fabric includes the following steps:

[0033] (1) Treat the dyed and dried nylon in a constant temperature and humidity box at 28°C and 60RH for 4 hours, then perform corona treatment, and treat it under 10kV for 4 seconds;

[0034] (2) After the corona treated textile is immersed in amino silicone waterproofing agent for 5 seconds, it is double-dipped and double-rolled, with a surplus rate of 70%, and dried at 130°C for 1 minute to obtain a soft and waterproof textile.

[0035] The preparation method of the amino organosilicon waterproof treatment agent is:

[0036] a. 0.3mol of octamethylcyclotetrasiloxane and 1mol of tetravinyltetramethoxycyclotetrasiloxane are distilled under reduced pressure at a pressure of 0.75MPa to remove low-boiling substances, and then 3molN-β -(Aminoethyl)-γ-aminopropylmethyldimethoxysilane and 0.003mol potassium hydroxide, reacted at 140℃ for 8h under normal pressure, then heated to 160℃, maintained at 0.75MPa a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com