Remote monitoring control system for multiple different types of numerical control machine tools and control method of system

A technology of CNC machine tools and remote monitoring, applied in general control systems, control/regulation systems, program control, etc., can solve the problems of difficult to improve the level of informatization, limited scalable functions, and rely on labor, and reduce on-site management costs. , reduce the dependence of human supervision and improve the effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

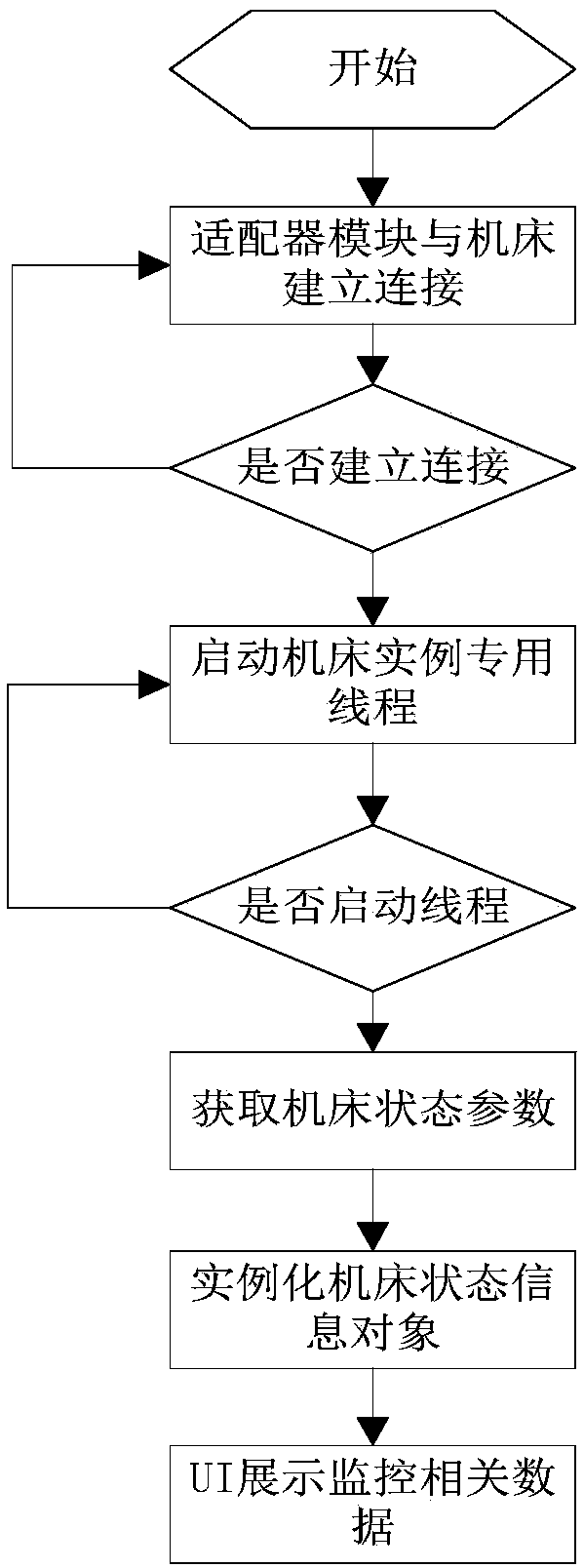

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

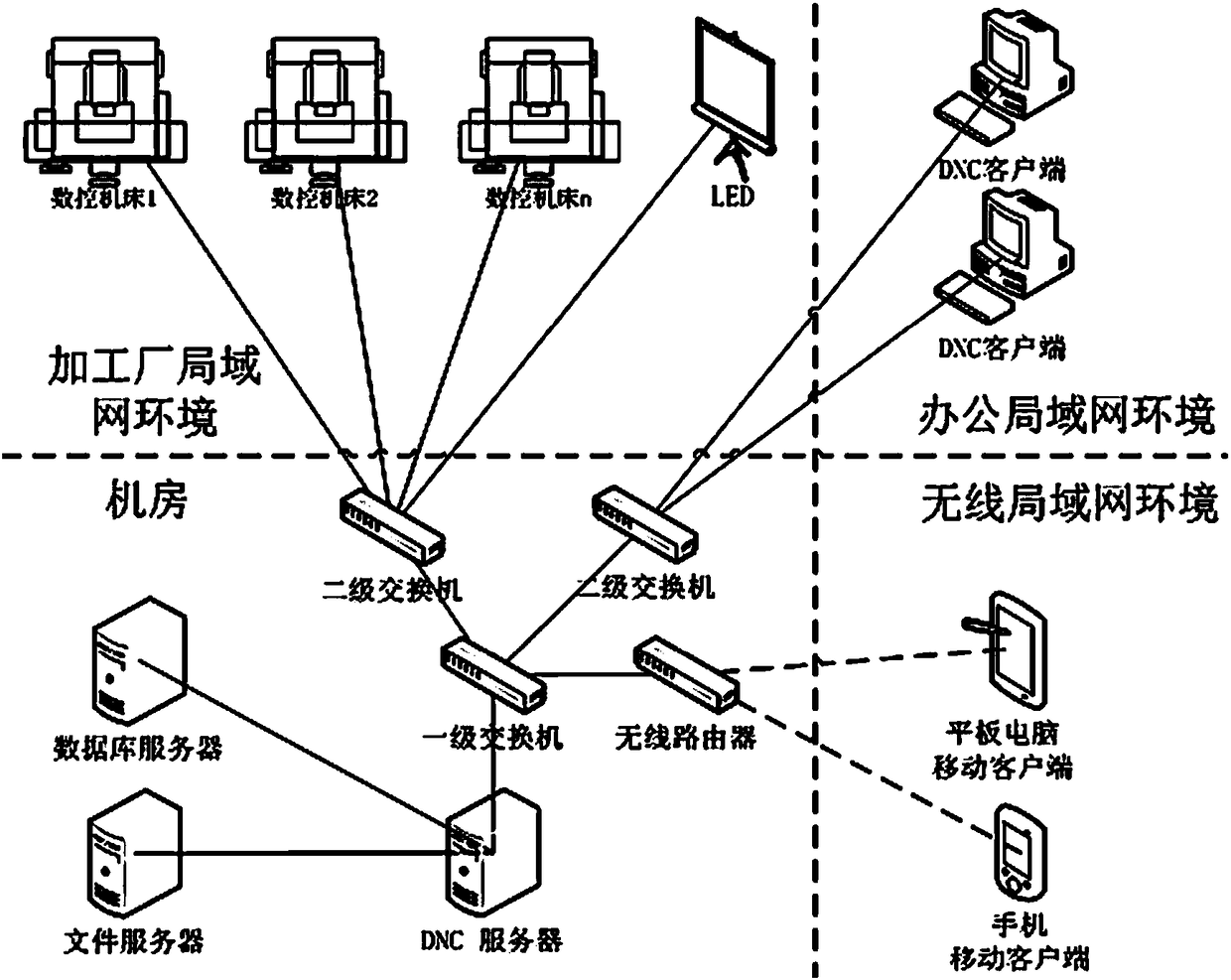

[0022] see figure 1 , The workshop network environment is a necessary condition for the implementation of the scheme of the present invention. When building a workshop LAN, depending on the situation of the CNC machine tool product, choose to directly connect to the network cable and merge it into the LAN, or convert serial data such as RS232 and RS485 to TCP / IP data, and then merge it into the LAN. The specific network building rules can be built according to the strategy of building a local area network on a PC.

[0023] In order to increase the file transfer rate, a gigabit switch can be used (when the number of CNCs is less than 100, 100M can also meet the demand). If the number of interfaces of the first-level switch is not enough to connect all devices, it can be expanded by hierarchical connection. Considering that the system needs to expand mobile t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com