Control system of mine clearance robot capable of parallel shifting

A control system and parallel movement technology, applied in general control systems, control/regulation systems, computer control, etc., can solve the problems of safety threats to mine sweepers, lack of precise remote control, etc., to achieve high promotion and practical value, improve safety performance and real-time, the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] specific implementation

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

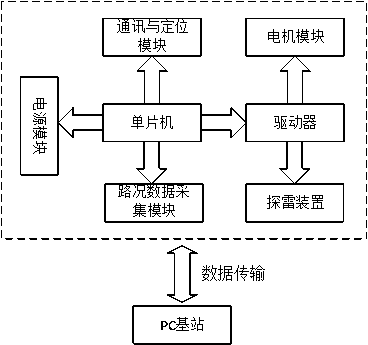

[0015] Such as figure 1 The schematic diagram of the overall structure of the system shown, the present invention includes the following components: a power supply module, a data acquisition module, a GPS positioning module, a wireless transmission module, a motor drive module and an information processing platform, and the control work is carried out around the core single-chip microcomputer. The location information is collected and generated, and the motor performs dangerous operations. The information processing platform processes the feedback information and then controls the robot.

[0016] The power supply unit adopts a voltage conversion chip to provide continuous and stable power supply for each component of the robot body.

[0017] The GPS positioning module is mainly to accurately locate the position coordinates of the rob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com