Metallographic corrosion solution and use method thereof

A technology of corrosion solution and concentrated hydrochloric acid, which is applied in the field of metallographic corrosion solution of C276 corrosion-resistant alloy, can solve the problems of difficult control of electrolytic corrosion, failure to obtain good metallographic corrosion effect, difficulty in finding rules, etc., and achieve clear grain boundaries Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Preparation of corrosion solution: 2g ferric chloride, 1.45g barium chloride, 22ml glacial acetic acid, 74ml concentrated hydrochloric acid, 20ml concentrated nitric acid.

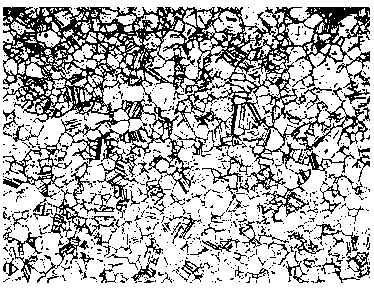

[0034] Use the prepared corrosive solution to corrode, put the sample in a glass dish, pour the prepared corrosive solution on the surface of the sample, let the corrosive solution soak the surface of the sample for about 2-5mm, and the corrosion time is about 10-5mm. After 30 minutes, it is observed that the surface of the sample is no longer bright, and when it becomes a pitted surface, the metallographic structure of the sample is completely corroded. Figure 1~2 It is a photomicrograph of the 1# sample after corrosion. The photo can corrode a clear C276 metallographic structure, making the twin structure clearly visible, and it is more convenient to measure the grain size. It provides a basis for customers to judge product quality, and enables manufacturers Benchmark products can be measured to ...

Embodiment 2

[0036] Preparation of corrosion solution: 2.2g ferric chloride, 1.5g barium chloride, glacial acetic acid 24ml, concentrated hydrochloric acid 72ml, concentrated nitric acid 23ml.

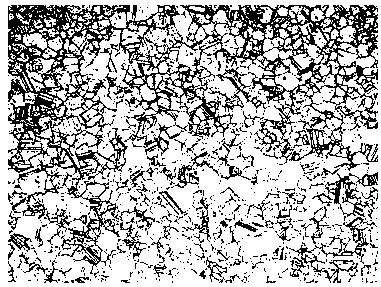

[0037] Figure 3-4 It is a photomicrograph of the 2# sample after corrosion. The photo can corrode a clear C276 metallographic structure, making the twin structure clearly visible, and it is more convenient to measure the grain size. It provides a basis for customers to judge product quality, and enables manufacturers Benchmark products can be measured to win the credit and satisfaction of customers, and at the same time improve the competitiveness of enterprises and bring objective economic benefits and benefits to enterprises.

Embodiment 3

[0039] Preparation of corrosion solution: 2.4g ferric chloride, 1.2g barium chloride, 20ml glacial acetic acid, 75ml concentrated hydrochloric acid, 20ml concentrated nitric acid.

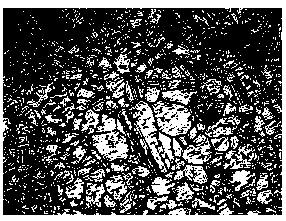

[0040] Figure 5 It is a photomicrograph of the 3# sample after corrosion. The photo can corrode a clear C276 metallographic structure, making the twin structure clearly visible, and it is more convenient to measure the grain size. It provides a basis for customers to judge product quality, and enables manufacturers Benchmark products can be measured to win the credit and satisfaction of customers, and at the same time improve the competitiveness of enterprises and bring objective economic benefits and benefits to enterprises.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com