A kind of cu-ni-si-mg alloy strip casting and rolling method and casting and rolling equipment

A cu-ni-si-mg, alloy plate technology, applied in metal rolling and other directions, can solve the problem of reducing the comprehensive performance indicators such as conductivity and strength of Cu-Ni-Si copper alloy, Cu-Ni-Si alloy casting The adverse effects of rolling slab performance indicators and the inclusion of various oxides can reduce the amount of milled surface peeling, enrich processing methods, and reduce oxidation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

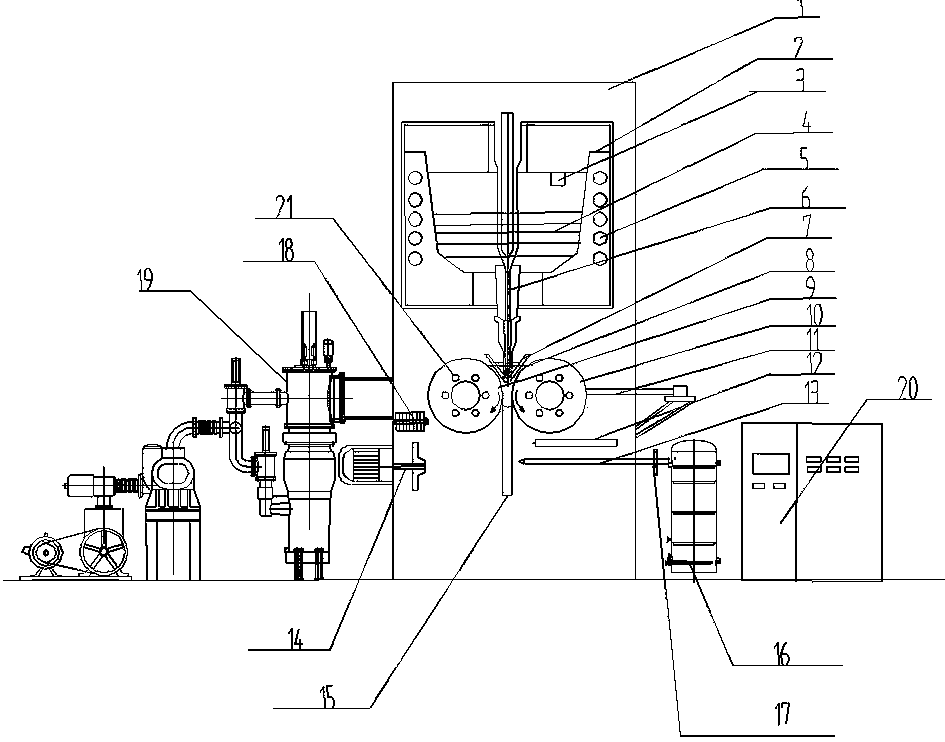

[0042] A method for casting and rolling a Cu-Ni-Si-Mg alloy sheet and strip, comprising the following steps.

[0043] 1) According to the mass ratio Cu:Ni:Si:Mg=94:2:0.5:0.07, weigh the cathode pure copper, industrial pure nickel, industrial pure silicon and industrial pure magnesium.

[0044] 2) Put the cathode pure copper and industrial pure nickel into the melting crucible 2, the vacuum degree in the equipment is less than 0.1Pa, heat it to 1250℃, and smelt it. After the smelting is completed, add the industrial pure silicon and industrial pure magnesium into the melt. Fully smelting and stirring to obtain Cu-Ni-Si-Mg alloy melt.

[0045] 3) After smelting, lift the stopper rod 6 to pour the Cu-Ni-Si-Mg alloy melt 4 into the casting mill through the distributor 7 for casting and rolling. During the implementation process, the rolls of the left casting roll 9 and the right casting roll 10 cooperate with each other. like Figure 5 As shown in the figure, a special-shaped "I...

Embodiment 2

[0048] A method for casting and rolling a Cu-Ni-Si-Mg alloy sheet and strip, comprising the following steps.

[0049] 1) According to the mass ratio Cu:Ni:Si:Mg=97:5:0.8:0.14, weigh the cathode pure copper, industrial pure nickel, industrial pure silicon and industrial pure magnesium.

[0050] 2) Put the cathode pure copper and industrial pure nickel into the melting crucible 2, the vacuum degree in the equipment is less than 0.1Pa, heat to 1280 ℃, and smelt, after the smelting is completed, add industrial pure silicon and industrial pure magnesium into the melt, Fully smelting and stirring to obtain Cu-Ni-Si-Mg alloy melt.

[0051] 3) After smelting, lift the stopper rod 6 to pour the Cu-Ni-Si-Mg alloy melt 4 into the casting mill through the distributor 7 for casting and rolling. During the implementation process, the rolls of the left casting roll 9 and the right casting roll 10 cooperate with each other. like Image 6 As shown in the figure, a special-shaped "toothed" se...

Embodiment 3

[0054] The method for casting and rolling a Cu-Ni-Si-Mg alloy sheet and strip includes the following steps:

[0055] 1) According to the mass ratio Cu:Ni:Si:Mg=96.2:3.0:0.7:0.1, weigh the cathode pure copper, industrial pure nickel, industrial pure silicon and industrial pure magnesium.

[0056] 2) Put the cathode pure copper and industrial pure nickel into the melting crucible 2, the vacuum degree in the equipment is less than 0.1Pa, heat it to 1260℃, and smelt it. After the smelting is completed, add the industrial pure silicon and industrial pure magnesium into the melt. Fully smelting and stirring to obtain Cu-Ni-Si-Mg alloy melt.

[0057] 3) After smelting, lift the stopper rod 6 to pour the Cu-Ni-Si-Mg alloy melt 4 into the casting and rolling mill through the distributor 7 for casting and rolling, and the thickness of the cast-rolled strip is 5 mm; the cast-rolled slab is exited from the casting roll The infrared thermometer 12 at the position measures the temperature,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com