Medium carbon alloy steel chain pin shaft heat treatment method

A heat treatment method and carbon alloy steel technology, applied in heat treatment furnaces, heat treatment equipment, metal material coating processes, etc., can solve the problems of poor stability and insufficient surface hardness of pins, and achieve high hardness, small hardness gradient, The effect of improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to facilitate the understanding of the present invention, the present invention will be described in detail below in conjunction with the preferred embodiments of the present invention given in the accompanying drawings.

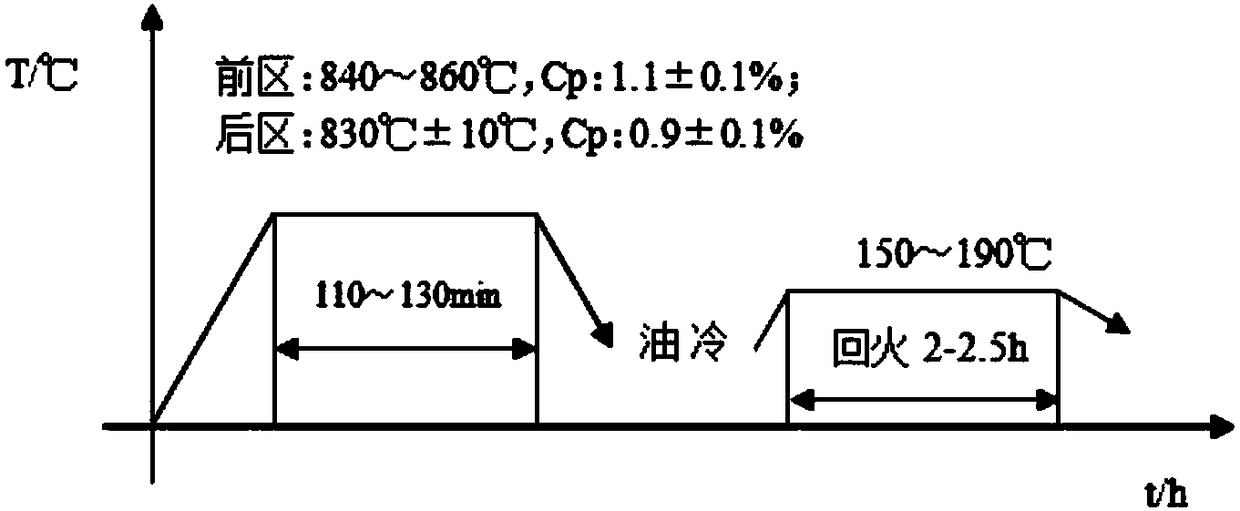

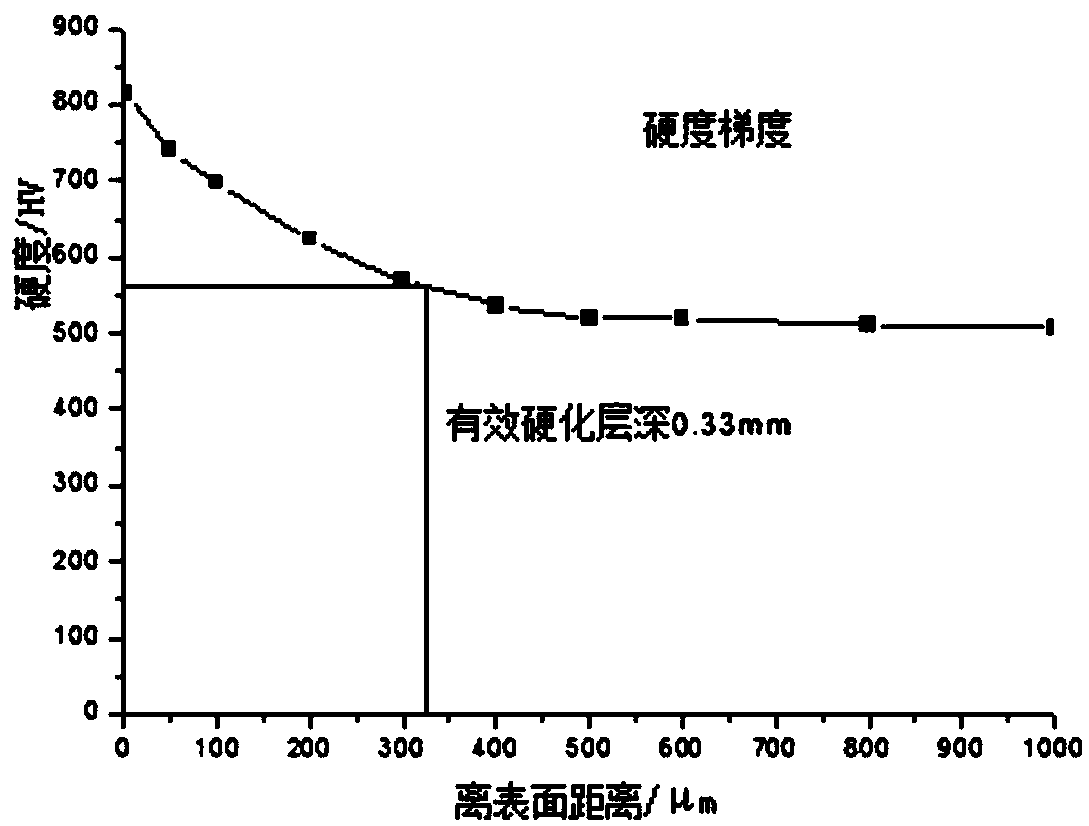

[0015] Such as figure 1 with figure 2 As shown, the heat treatment method of a medium-carbon alloy steel chain pin shaft of the present invention adopts the carbonitriding quenching and tempering treatment process of adjusting the temperature and carbon potential in the front and rear areas of the mesh belt furnace, and cold-extrudes the chain with the fillet in place. After the pin shaft is put into the drum for cleaning and drying, it is put into the controlled atmosphere mesh belt furnace, and the controlled atmosphere mesh belt furnace is fed with propane and NH at the same time. 3 and methanol, NH 3 The total feed rate is 400-450L / h, the total feed rate of methanol is 2.5-3.8L / h, the temperature and carbon potential are set in differe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com