A kind of porphyrin organic framework hybrid and its preparation method

An organic framework and hybrid technology, applied in the field of porphyrin organic framework hybrids and their preparation, can solve the problems of limiting the application of organic framework hybrids, difficult to achieve batch preparation and production, staying in the model experiment stage, etc. The effect of interface structure, uniform morphology, high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] A kind of preparation method of porphyrin organic framework hybrid provided by the invention, it specifically comprises the following steps:

[0026] 1) Fully dissolve the five-membered heterocycle, polyaldehyde, complexing agent, acid and oxidant in an organic solvent to form a solution; wherein the ratio of the amount of five-membered heterocycle to polyaldehyde is 1:0.1-1: 10; The ratio of the five-membered heterocycle to the amount of the complexing agent is 1:0.1-1:10; the five-membered heterocycle is one or more of pyrrole, furan and thiophene; the polyaldehyde It has 3 or more carbons and has more than 2 aldehyde groups; the complexing agent is a hydrochloride, nitrate or sulfate of one of Mn, Fe, Co, Ni, Cu or Zn; Said acid is one or more mixtures of formic acid, acetic acid, propionic acid, hydrochloric acid, sulfuric acid, p-toluenesulfonic acid, trifluoroformic acid and trifluoroacetic acid; said oxidizing agent is nitrobenzene, dinitrobenzene benzene, trini...

Embodiment 1

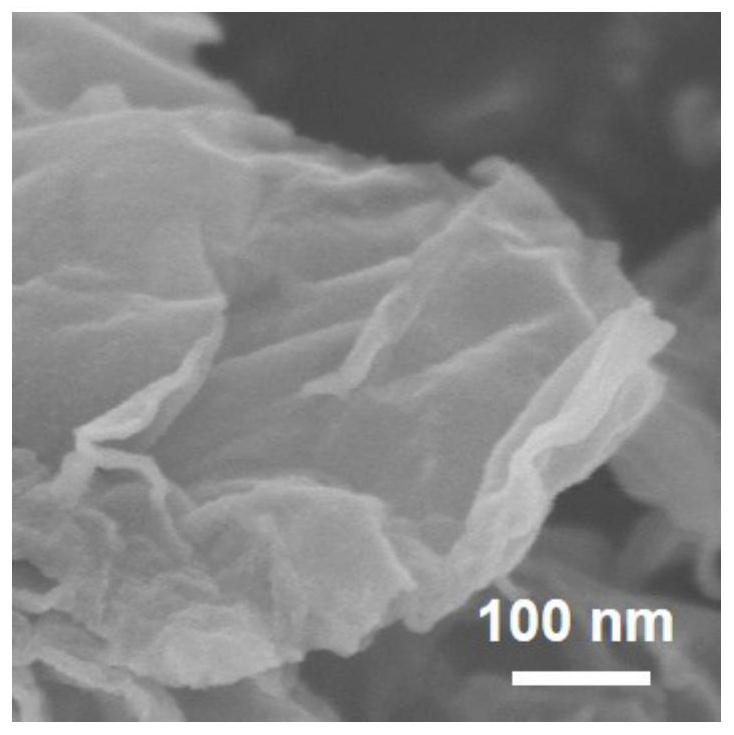

[0031] Weigh 1.3g of terephthalaldehyde and add it into 250mL of tetrahydrofuran, stir and fully dissolve. Add 1.4 mL of pyrrole, 0.5 mL of trifluoroacetic acid and 1.0 mL of nitrobenzene to the above solution in sequence, and form a uniform solution under stirring. Add 260mg of graphene powder, stir well to disperse it evenly and transfer it into a 500mL flask. The flask was placed in an oil bath at 150° C. under constant stirring for 24.0 hours to react at a constant temperature. After the reaction solution was cooled, the reaction solution was suction filtered to obtain a crude product. The crude product was washed with ethanol, chloroform and deionized water respectively and filtered. The washed product was dried at 60° C. for 24.0 hours to prepare a hybrid of H-coordinated N-porphyrin organic framework and graphene. The final product was a black powder with a yield of 97%.

Embodiment 2

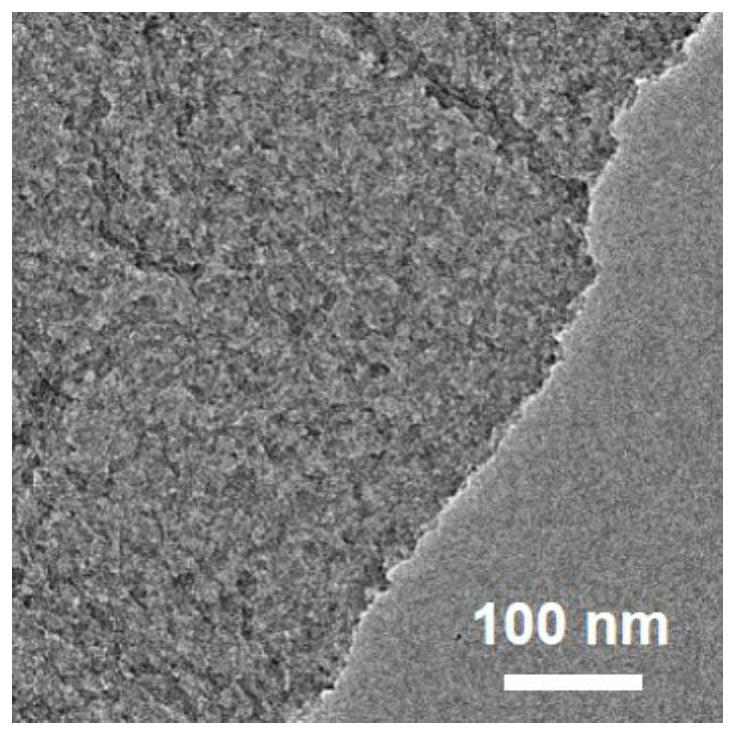

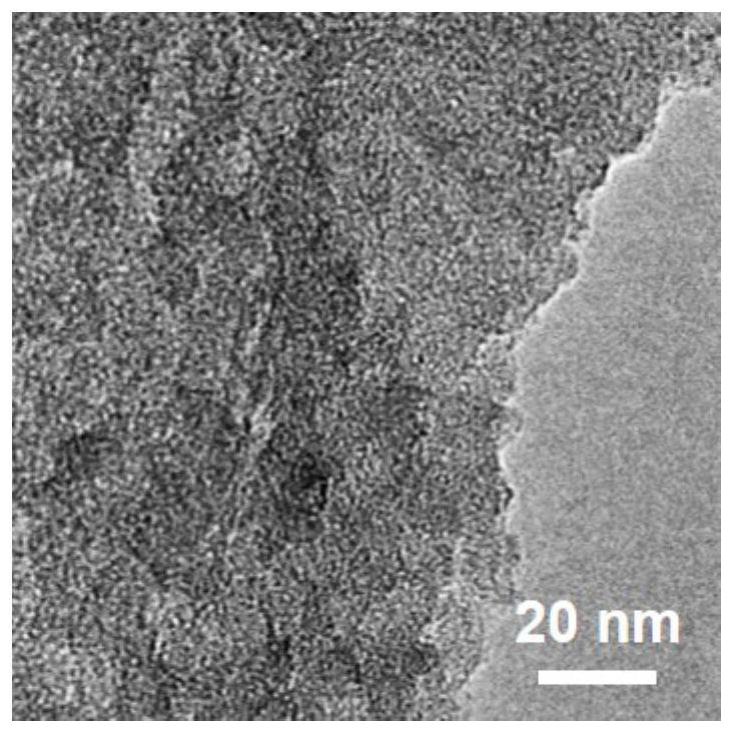

[0033]Weigh 2.7g of terephthalaldehyde, 5.4g of cobalt chloride and 2.5g of potassium nitrate into 500mL of chloroform, stir and fully dissolve. Add 1.5mL of pyrrole, 1.7mL of thiophene and 1.0mL of hydrochloric acid in sequence to the above solution, and form a uniform solution under stirring. Add 1.5 g of carbon black, stir well to disperse evenly and transfer to a 1 L flask. The flask was placed in an oil bath at 180° C. under constant stirring for 6.0 hours at a constant temperature. After the reaction solution was cooled, the reaction solution was suction filtered to obtain a crude product. The crude product was washed three times each with ethanol and filtered. The washed product was dried at 60° C. for 24.0 hours to prepare a hybrid of Co-coordinated S-porphyrin organic framework and carbon black. The final product was a black powder with a yield of 99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com