A kind of UV light curing anti-fog resin and its preparation method and application

A light-curing and anti-fog technology, applied in the direction of coating, etc., can solve the problems of short anti-fog service life, poor substrate adhesion, resistance to scratches and friction, etc., and achieve fast curing speed, good mechanical properties, and stability good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1 A kind of UV light curing anti-fog resin 1

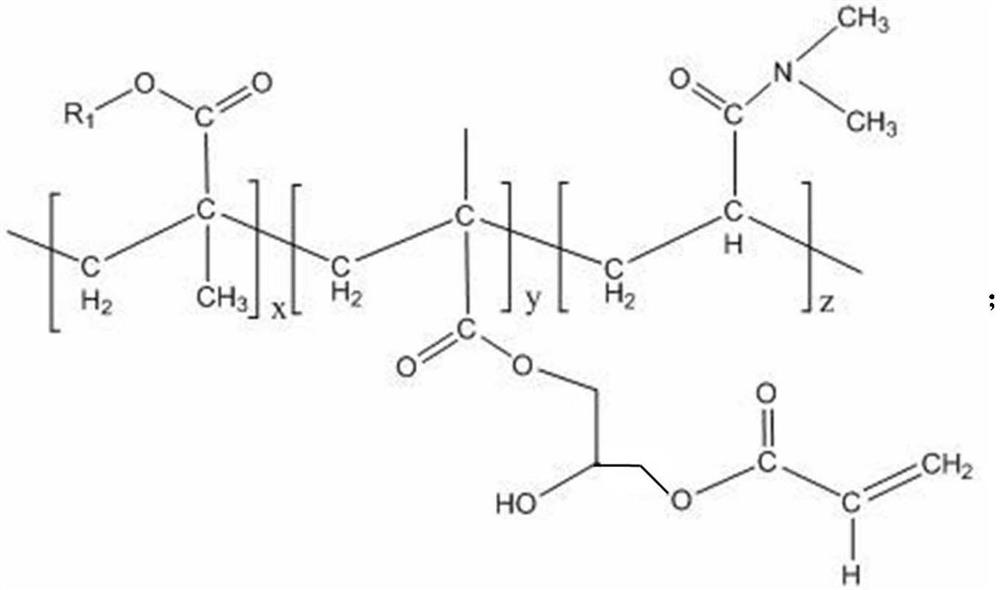

[0038] A kind of UV photocurable antifog resin, the molecular weight of described antifog resin is about 1800, and the structural formula of described UV photocurable antifog resin is as follows:

[0039]

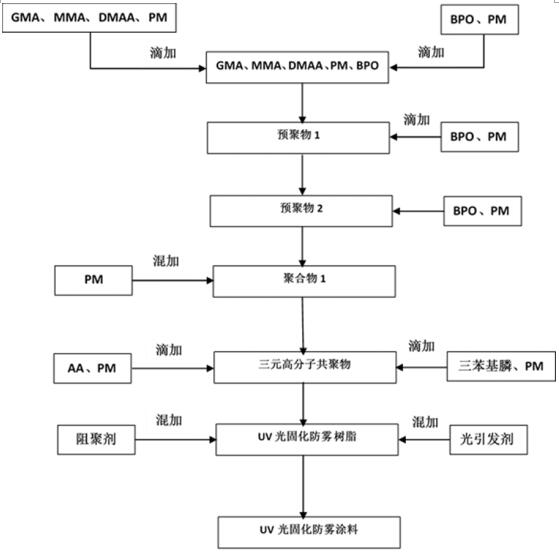

[0040] The preparation method of above-mentioned UV photocuring anti-fog resin is as follows:

[0041] S1: The appropriate amount of 8.92%wt benzoyl peroxide-propylene glycol monomethyl ether solution is prepared as mixed solution 1, and the appropriate amount of 5.66%wt triphenylphosphine-propylene glycol monomethyl ether solution is mixed solution 2, and the molar ratio is methacrylic acid Glycerides: methyl methacrylate: N, N-dimethylacrylamide = 3:2:12 16.0%wt propylene glycol monomethyl ether solution The appropriate amount is mixed solution 3, 15.6%wt acrylic acid-propylene glycol monomethyl ether solution An appropriate amount is the mixed solution 4, set aside.

[0042] S2: Mix part of the mixed s...

Embodiment 2

[0044] Embodiment 2 A kind of UV light curing anti-fog resin 2

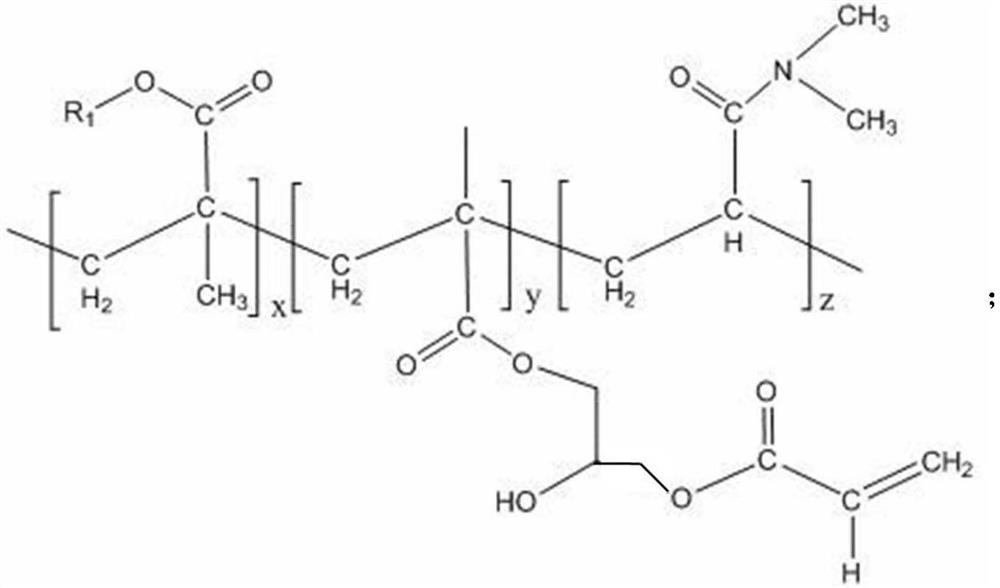

[0045] A kind of UV photocurable antifog resin, the molecular weight of described antifog resin is about 2500, and the structural formula of described UV photocurable antifog resin is as follows:

[0046]

[0047] The preparation method of above-mentioned UV photocuring anti-fog resin is as follows:

[0048]S1: The appropriate amount of 8.95%wt benzoyl peroxide-propylene glycol monomethyl ether solution is prepared as mixed solution 1, and the appropriate amount of 5.47%wt triphenylphosphine-propylene glycol monomethyl ether solution is mixed solution 2, and the molar ratio is methacrylic acid Glycerides: methyl methacrylate: N, N-dimethylacrylamide = 5:5:11 15.98%wt propylene glycol monomethyl ether solution is an appropriate amount of mixed solution 3, 16.4%wt acrylic acid-propylene glycol monomethyl ether solution An appropriate amount is the mixed solution 4, set aside.

[0049] S2: Mix part of the mixed...

Embodiment 3

[0051] Embodiment 3 A kind of UV light curing anti-fog resin 3

[0052] A kind of UV photocurable antifog resin, the molecular weight of described antifog resin is about 3000, and the structural formula of described UV photocurable antifog resin is as follows:

[0053]

[0054] The preparation method of above-mentioned UV photocuring anti-fog resin is as follows:

[0055] S1: The appropriate amount of 9.05%wt benzoyl peroxide-propylene glycol monomethyl ether solution is prepared as mixed solution 1, and the appropriate amount of 5.39%wt triphenylphosphine-propylene glycol monomethyl ether solution is mixed solution 2, and the molar ratio is methacrylic acid Glycerides: methyl methacrylate: N,N-dimethylacrylamide: = 7:2:15 15.2%wt propylene glycol monomethyl ether solution The appropriate amount is mixed solution 3, 16.4%wt acrylic acid-propylene glycol monomethyl ether The appropriate amount of the solution is the mixed solution 4, which is set aside.

[0056] S2: Mix pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com