Biological organic fertilizer preparation technology

A bio-organic fertilizer and preparation process technology, applied in the field of bio-organic fertilizer preparation process, can solve problems such as affecting plant growth and soil structure, low fertilizer effectiveness, decomposition and heat generation, etc., to improve product quality, low cost, and save time and cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

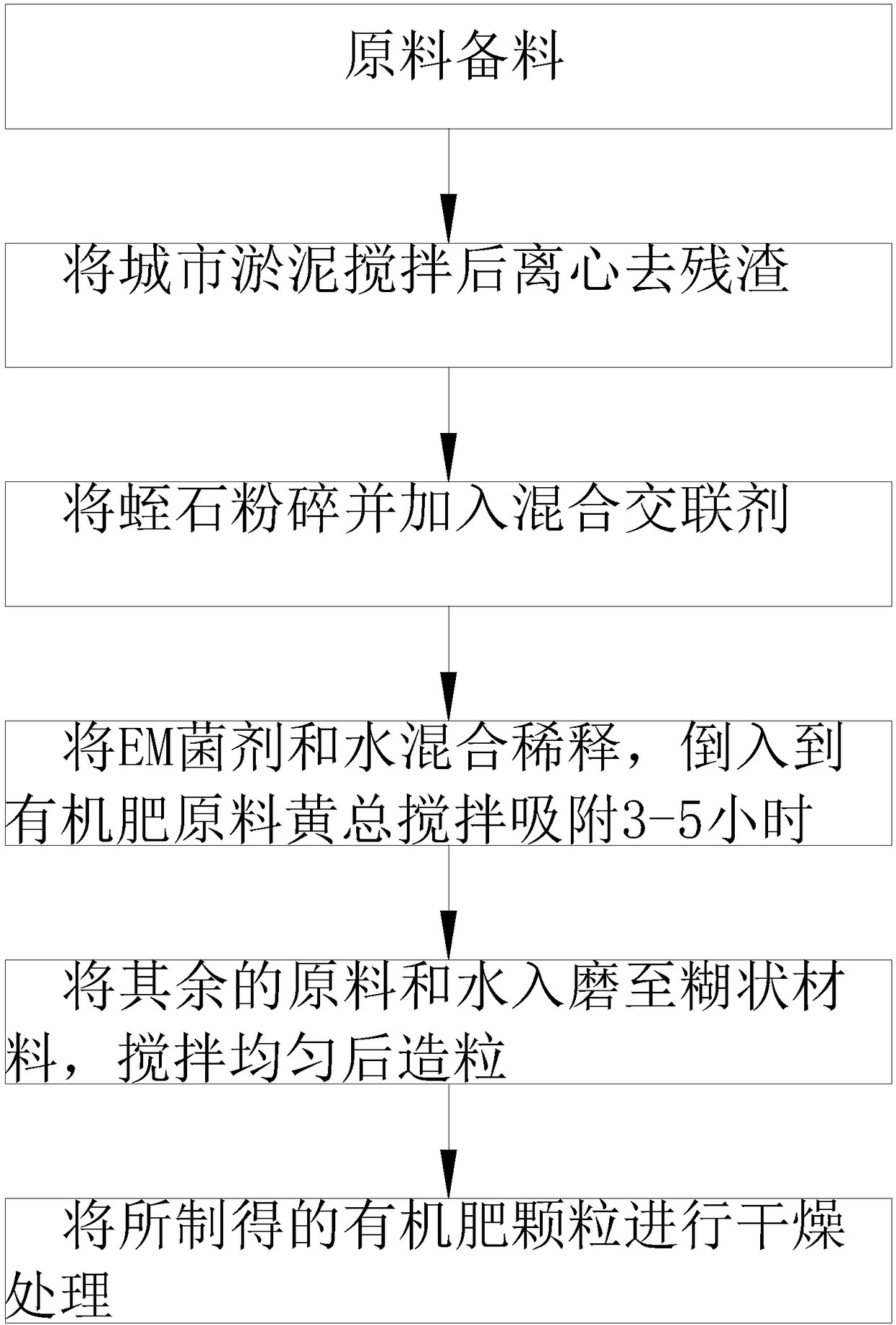

[0032] A kind of bio-organic fertilizer preparation process of the present invention is characterized in that making according to the following steps:

[0033] Step 1: Prepare materials: urban sludge, vermiculite, EM bacteria agent, wheat bran, dry cow dung, soybean meal, cross-linking agent and water;

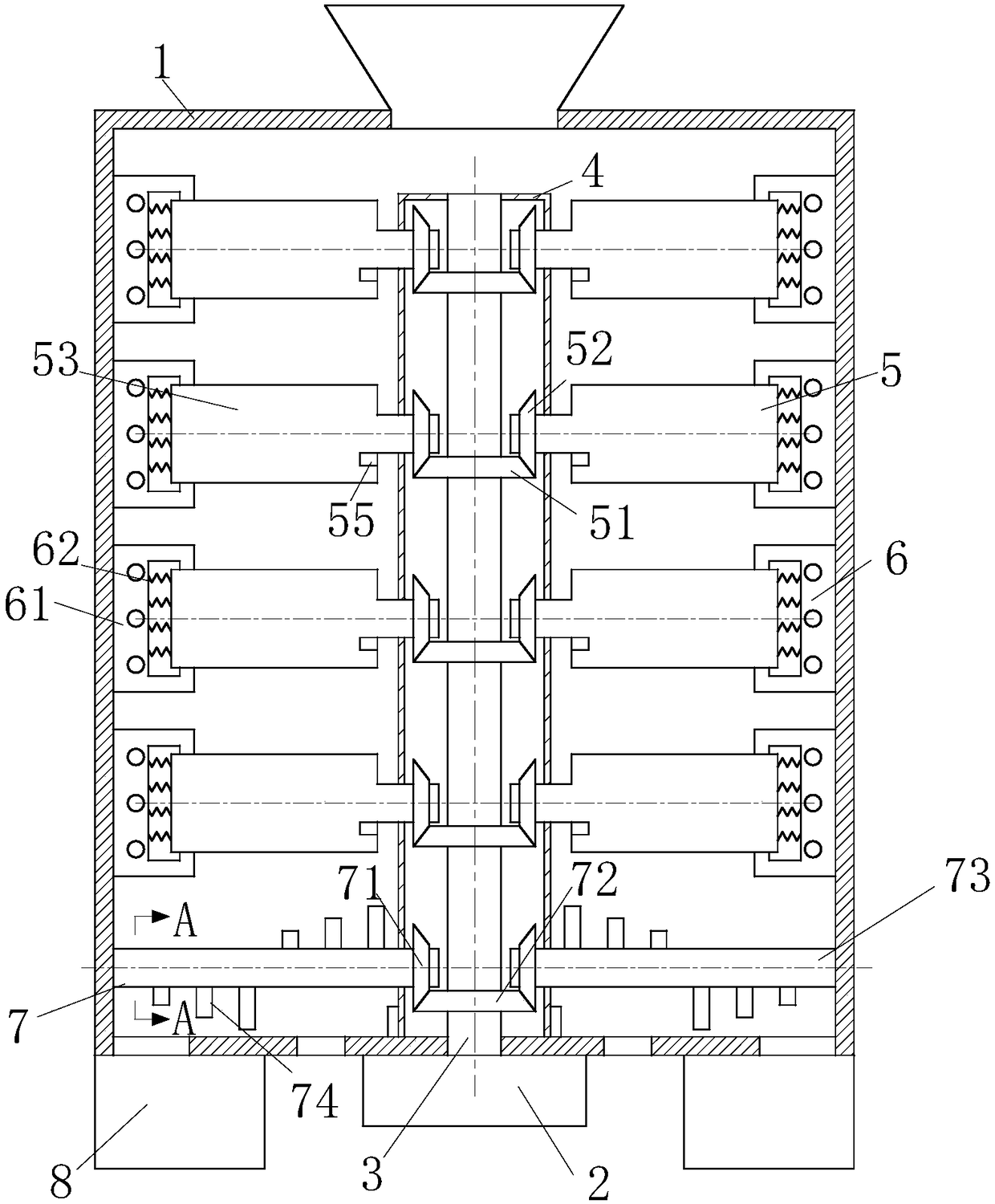

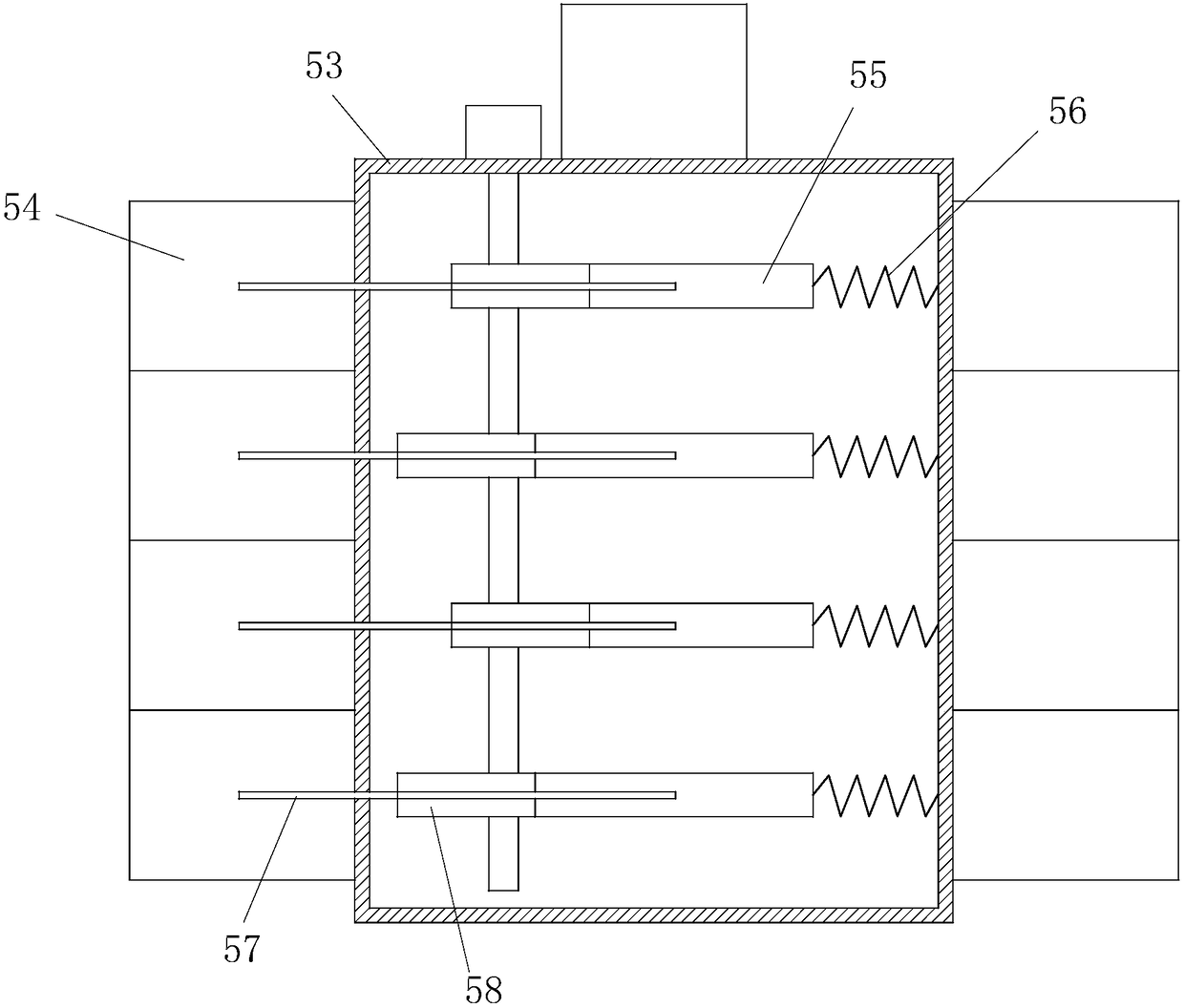

[0034] Step 2: Add urban silt into the housing 1 through the feeding port, the stirring plate 53 rotates with the rotating shaft 3, the stirring plate 53 not only revolves around the rotating shaft 3, but also rotates on its own, the stirring effect is good, and the stirring plate 53 is also set There is a horizontal plate 54 to improve the stirring efficiency again. The horizontal plate 54 can be rotated, and the large particle residue at the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com