A method for forming a thin-walled conical cylindrical ceramic matrix composite component

A composite material component and forming method technology, which is applied in the forming field of ceramic matrix composite materials, can solve problems such as wrinkles, achieve stable shaping, uniform fiber volume fraction, and ensure the effect of component forming accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] 1. Preparation of fiber prefabricated body 1: using continuous fibers (such as carbon fiber, silicon carbide fiber, etc.) as raw materials, weaving and preparing fiber prefabricated body 1 according to the structure, shape and size of the proposed component;

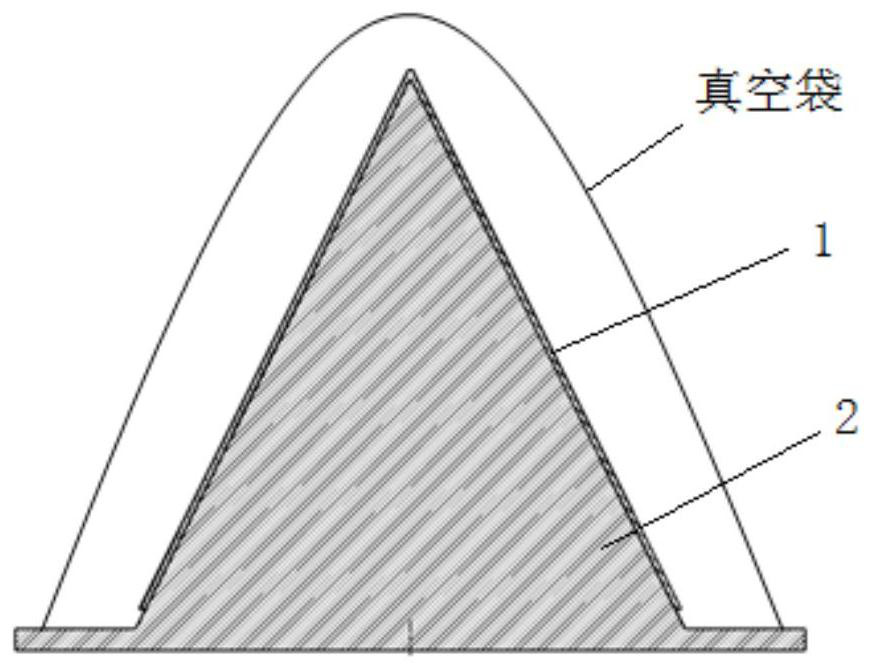

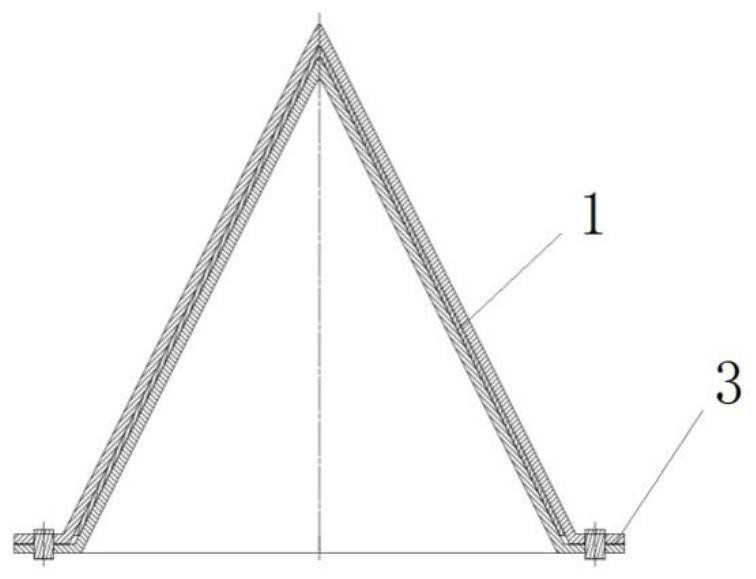

[0028] 2. Design and manufacture of shaping molds: design and manufacture shaping molds according to the structure, shape and size of the components to be formed; including manufacturing the male mold 2 for autoclave forming according to the internal surface of the components, and according to the internal and external shapes of the components Conformal mold 3 in the subsequent densification process of surface manufacturing;

[0029] 3. Preparation of the interface layer: the fiber preform 1 is placed in a chemical vapor deposition furnace to coat the interface layer on the surface of the fiber. The interface layer is composed of pyrolytic carbon, silicon carbide or boron nitride materials. The preparation process...

Embodiment

[0038] A method for forming a thin-walled conical ceramic matrix composite member, the operation steps are as follows:

[0039] 1. Preparation of fiber prefabricated body 1: using continuous silicon carbide fiber as raw material, weaving and preparing fiber prefabricated body 1 according to the structure, shape and size of the simulated component;

[0040] 2. Design and manufacture of shaping molds: design and manufacture shaping molds according to the structure, shape and size of the components to be formed; including manufacturing the male mold 2 for autoclave forming according to the internal surface of the components, and according to the internal and external shapes of the components Conformal mold 3 in the subsequent densification process of surface manufacturing;

[0041] 3. Preparation of the interface layer: the fiber preform 1 is placed in a chemical vapor deposition furnace to coat the interface layer on the surface of the fiber. The interface layer is composed of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com