Hydrogen electrode of solid oxide electrolytic cell and preparation method thereof, solid oxide electrolytic cell

A solid oxide, electrolytic cell technology, applied in the direction of electrodes, electrolysis components, electrolysis process, etc., can solve the problems of reduced hydrogen electrode stability, reduced three-phase interface, poor uniformity and controllability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] The preparation method of the solid oxide electrolytic cell of the embodiment of the present application comprises the following steps:

[0052] 1) Preparation of SOEC hydrogen electrode supporter containing NiO and YSZ (yttria-stabilized zirconia): the NiO and YSZ powders are uniformly mixed with the first pore-forming agent by ball milling for 6 to 12 hours, and an appropriate amount of the mixed powder is put into the mold , warm press forming, the thickness is 100~1000μm, and then pre-sintered at 1000~1500℃ for 2h, the hydrogen electrode support body also serves as the support body of the whole battery;

[0053] 2) The hydrogen electrode of the solid oxide electrolytic cell of the present application is the hydrogen electrode functional layer, and its preparation method is: uniformly mix NiO, YSZ powder, the second pore-forming agent and solvent, and coat it on the hydrogen electrode support body. The surface, with a thickness of 5-25 μm, is fully dried in the air a...

Embodiment 1

[0066] The present embodiment provides a solid oxide electrolytic cell, and the specific steps are as follows:

[0067] 1) First prepare the SOEC hydrogen electrode supporter containing NiO and yttria-stabilized zirconia (hereinafter referred to as YSZ): the NiO and YSZ powders and the graphite pore-forming agent are uniformly mixed in a mass ratio of 1:1:0.2 by ball milling for 10h to obtain For the first mixture, take the mixed first mixture and put it into a mold, and then warm-press to form a square sheet-shaped support with a side length of 7 cm and a thickness of 300 μm. ; Wherein, the hydrogen electrode support is also used as the support of the entire solid oxide electrolytic cell;

[0068] 2) Preparation of hydrogen electrode functional layer: Mix NiO and YSZ powders, the mass ratio of NiO and YSZ powders is 2:1, the particle size of YSZ powders is 60-100nm, and then PS spherical pore formers and pore formers are added. The mass is 10% of the total mass of NiO and YS...

Embodiment 2

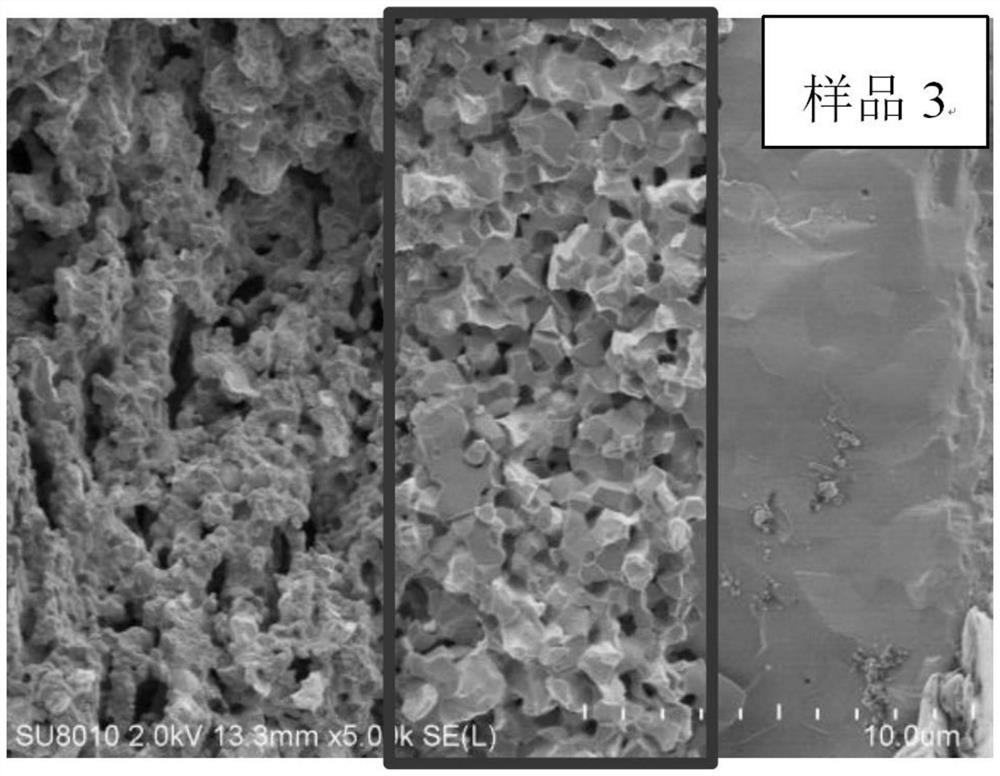

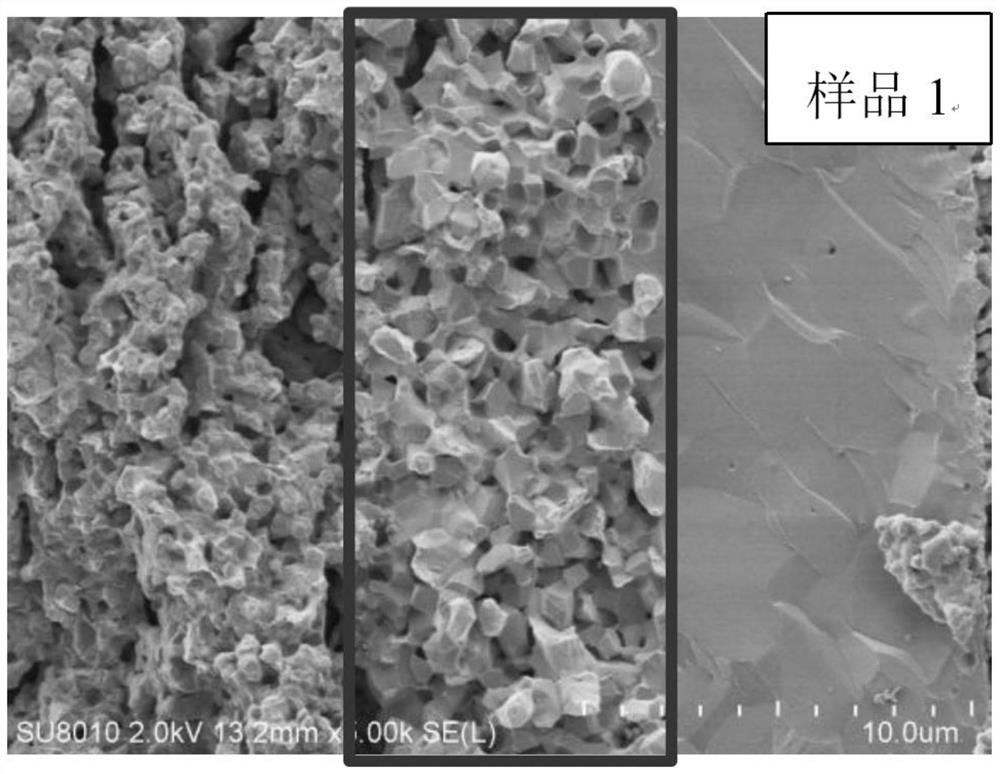

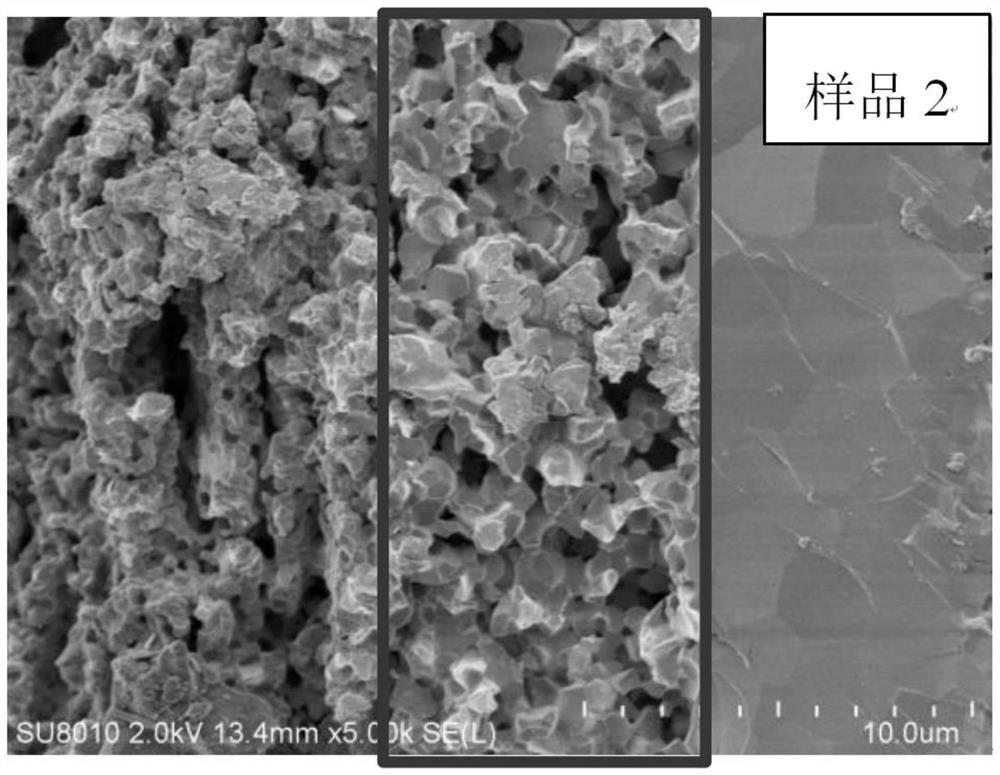

[0087] In this example, scanning electron microscopy and performance testing are performed on Sample 1, Sample 2 and Sample 3 prepared in Example 1 and Comparative Examples 1-2. Table 1 shows the structural characteristics of the hydrogen electrode functional layer of Sample 1, Sample 2 and Sample 3.

[0088] Table 1

[0089]

[0090]

[0091] 1. Scanning electron microscopy was performed on the sections of sample 1, sample 2 and sample 3, and the results were as follows Figures 1 to 4 shown, figure 1 The cross-sectional SEM picture of sample 3 provided in the embodiment of the present application; wherein, inside the frame is the hydrogen electrode functional layer area; figure 2 A cross-sectional SEM picture of sample 1 provided in the embodiment of the present application; wherein, the inside of the frame is the hydrogen electrode functional layer area; image 3 The cross-sectional SEM picture of sample 2 provided in the embodiment of the present application; whe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com