Ocean vessel ballast water treatment barge for port operation

A technology for ocean-going ships and ballast water, which is applied in the field of marine ecology and environmental protection, and can solve problems such as bulky size, poor applicability in sea areas, and complex chlorine gas emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

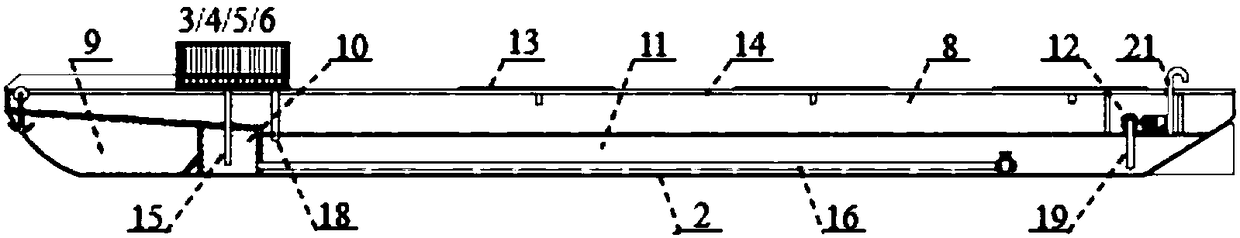

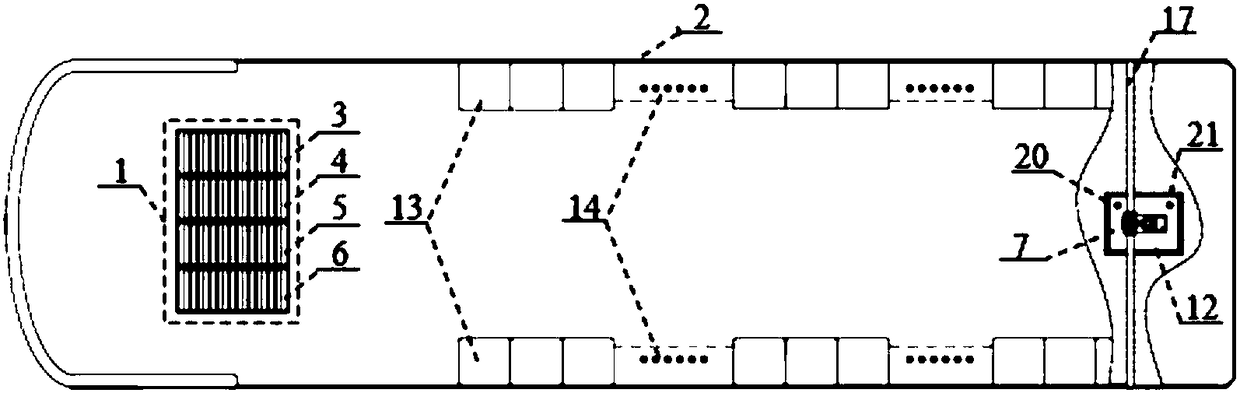

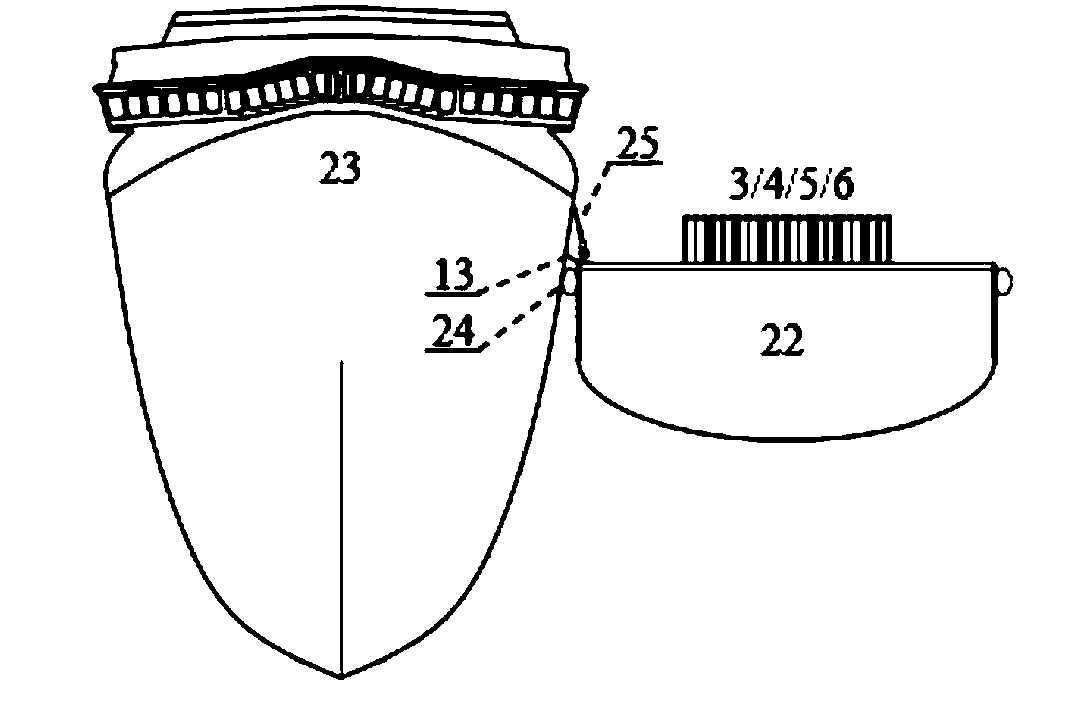

[0034] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

[0035] The principle structure of a ballast water treatment barge for ocean-going ships used in port operations according to the present invention is shown in Figure 1(a) and Figure 1(b), including a containerized ballast water advanced oxidation treatment system 1 and the ballast water collection and treatment hull 2, the containerized ballast water advanced oxidation treatment system 1 is installed on the deck of the ballast water collection and treatment hull 2, and is connected through a ballast water delivery pipeline. The ocean-going ship ballast water treatment barge is not equipped with a self-propelled propulsion system, and is towed in place by a tugboat during work.

[0036] The packaged ballast water advanced oxidation treatment system 1 includes: a packaged power supply box 3, a packaged gas storage box...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com