Edible biological product for eliminating flatulence and repairing and nursing gastric mucosa

A technology of biological products and gastric mucosa, which is applied in the field of preparation of edible biological products, can solve the problems that the repair of gastric mucosal damage in the gastrointestinal system has no therapeutic and repairing effect, can not solve the repeated problems of symptoms, and cannot completely repair gastric mucosal damage, etc. , to achieve the effects of relieving and eliminating gastrointestinal polyps, eliminating gastric mucosal damage, and repairing gastrointestinal mucosal damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

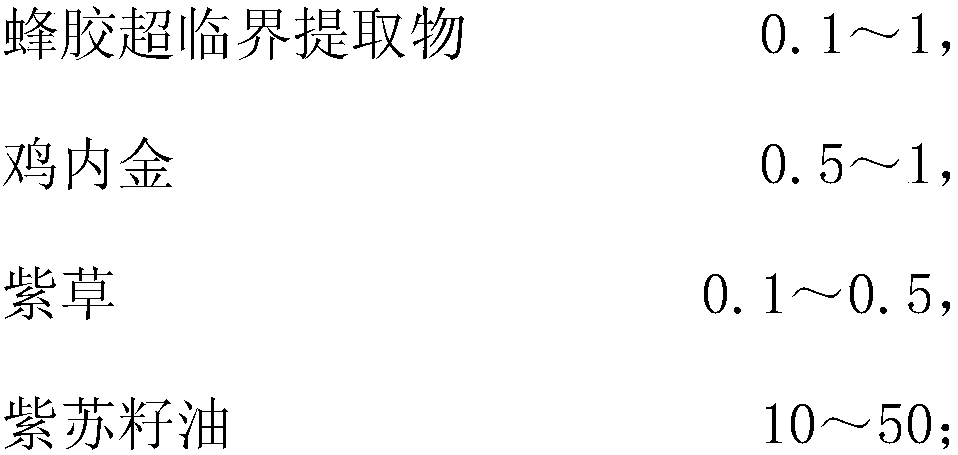

Method used

Image

Examples

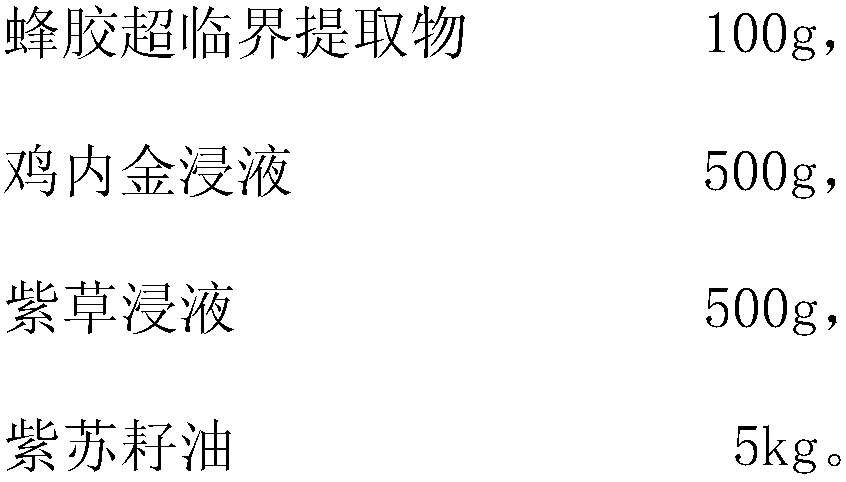

Embodiment 1

[0034] (1), prepare the pharmaceutical ingredient raw materials of edible biological products according to the following method:

[0035] Propolis supercritical extract: loading raw propolis into CO 2 Supercritical extraction tank, cyclically adding CO 2 The liquid is subjected to supercritical extraction, the extraction temperature is 25 DEG C, the extraction pressure is 10 MPa, and the extraction time is 1 hour, to obtain 1% to 1.5% of the natural propolis supercritical extract that does not contain heavy metals and is bright yellow in color and contains plant flavonoids.

[0036] Perilla seed oil: Put the perilla seeds into the press, press at room temperature, and get the perilla seed oil containing a-linolenic acid by leaching.

[0037] Chicken Neijin Infusion: Immerse 500 g of the broken chicken Neijin into 5000 g of the above-mentioned perilla seed oil at 60 to 80°C, keep the temperature for 8 hours, and then centrifuge at low temperature to obtain the oil component of...

Embodiment 2

[0046] (1), prepare the pharmaceutical ingredient raw materials of edible biological products according to the following method:

[0047] Propolis supercritical extract: loading raw propolis into CO 2 Supercritical extraction tank, cyclically adding CO 2 The liquid is subjected to supercritical extraction, the extraction temperature is 25 DEG C, the extraction pressure is 10 MPa, and the extraction time is 1 hour, to obtain 1% to 1.5% of the natural propolis supercritical extract that does not contain heavy metals and is bright yellow in color and contains plant flavonoids.

[0048] Perilla seed oil: Put the perilla seeds into the press, press at room temperature, and get the perilla seed oil containing a-linolenic acid by leaching.

[0049] Chicken Neijin Infusion: Immerse 300g of the broken chicken Neijin into 5000g of the above-mentioned perilla seed oil at 60-80°C, keep the temperature for 6 hours, and then centrifuge at low temperature to obtain the oily chicken Neijin d...

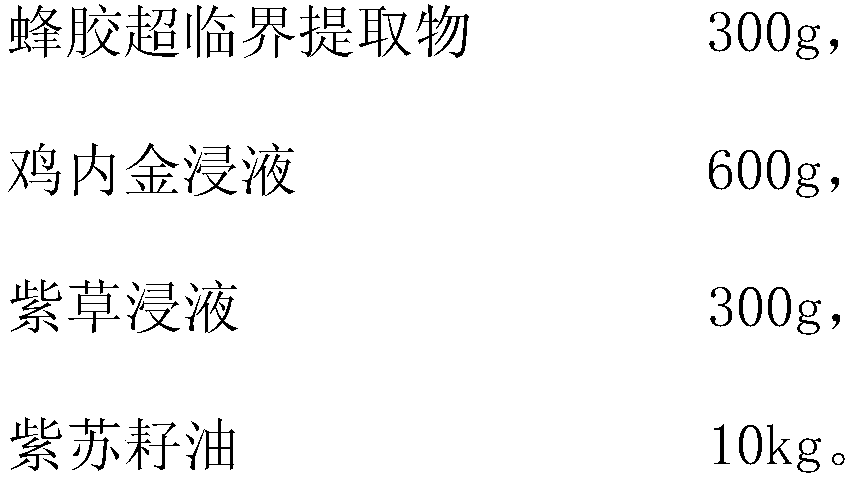

Embodiment 3

[0058] (1), prepare the pharmaceutical ingredient raw materials of edible biological products according to the following method:

[0059] Propolis supercritical extract: loading raw propolis into CO 2 Supercritical extraction tank, cyclically adding CO 2 The liquid is subjected to supercritical extraction, the extraction temperature is 25 DEG C, the extraction pressure is 10 MPa, and the extraction time is 1 hour, to obtain 1% to 1.5% of the natural propolis supercritical extract that does not contain heavy metals and is bright yellow in color and contains plant flavonoids.

[0060] Perilla seed oil: Put the perilla seeds into the press, press at room temperature, and get the perilla seed oil containing a-linolenic acid by leaching.

[0061] Chicken Neijin Infusion: Immerse 500 g of the broken chicken Neijin into 5000 g of the above-mentioned perilla seed oil at 60 to 80°C, keep the temperature for 8 hours, and then centrifuge at low temperature to obtain the oil component of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com