Processing method and device of low-toxicity ginkgo seeds

The technology of a processing device and processing method is applied in the field of processing method and device of low-toxic ginkgo kernels, which can solve problems such as loss, pollution of nutrients, excessive ginkgolic acid content, etc., and achieve the effects of improving product quality, saving energy, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

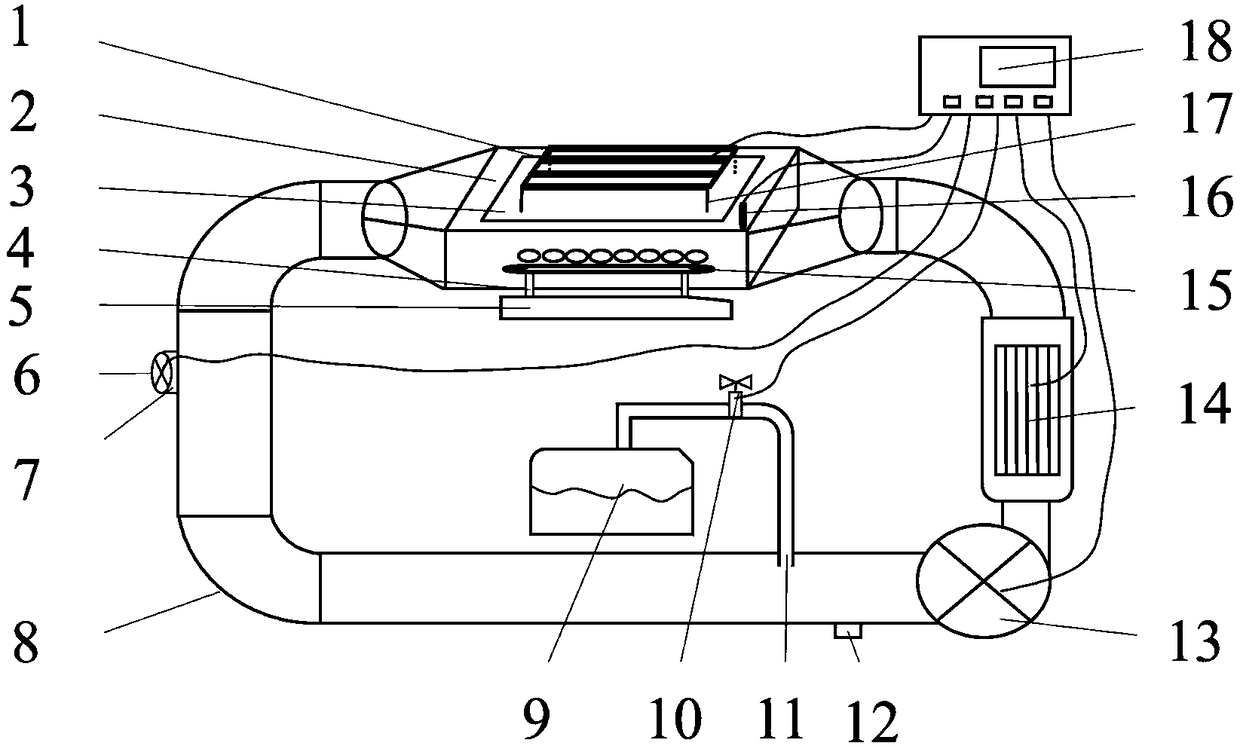

Image

Examples

Embodiment 1

[0040] ①Set the drying conditions as follows: the drying temperature is 70°C, the wind speed is 10m / s, the relative air humidity is 25%RH in the early stage, and the duration is 30min; the relative air humidity in the middle stage is 10%RH, and the duration is 3h; 5% RH, until the end of drying; ②Remove the shell and red coat of fresh ginkgo, and place it on the drying tray after the temperature and humidity in the drying room are stable; ③Turn on the ultraviolet rays, and the ultraviolet intensity is 0.2W / m 2 , the UV radiation dose is 1kJ / m 2 4. After drying for about 11 hours, the moisture content of the ginkgo is about 11%. 5. When the ginkgo is cooled to room temperature, the content of ginkgolic acid in the low-toxic ginkgo kernel is about 18.98mg / kg, which is about 57.82% lower than that of fresh ginkgo.

Embodiment 2

[0042] ①Set the drying conditions as follows: the drying temperature is 50°C, the wind speed is 20m / s, the relative air humidity is 60%RH in the early stage, and the duration is 60min; the relative air humidity in the middle stage is 25%RH, and the duration is 4h; 5% RH, until the end of drying; ②Remove the shell and red coat of fresh ginkgo, and place it on the drying tray after the temperature and humidity in the drying room are stable; ③Turn on the ultraviolet rays, and the ultraviolet intensity is 0.2W / m 2 , the UV radiation dose is 20kJ / m 2 ; ④ After drying for about 38 hours, the moisture content of the ginkgo is about 11%. Its ginkgolic acid content is about 15.64mg / kg, which is about 65.24% lower than that in fresh ginkgo.

Embodiment 3

[0044] ①Set the drying conditions as follows: the drying temperature is 90°C, the wind speed is 3m / s, the relative humidity of the air in the early stage is 30%RH, and the duration is 15min; the relative air humidity in the middle stage is 15%RH, and the duration is 4h; 5% RH, until the end of drying; ②Remove the shell and red coat of fresh ginkgo, and place it on the drying tray after the temperature and humidity in the drying room are stable; ③Turn on the ultraviolet light, and the ultraviolet intensity is 10W / m 2 , the UV radiation dose is 20kJ / m 2 ; ④ After drying for about 8 hours, the water content of ginkgo is about 11%. Its ginkgolic acid content is about 17.83mg / kg, which is about 60.37% lower than that in fresh ginkgo.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com