Solid feed containing propylene glycol and preparation method thereof

A propylene glycol, solid-state technology, applied in the field of feed, can solve problems such as reporting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

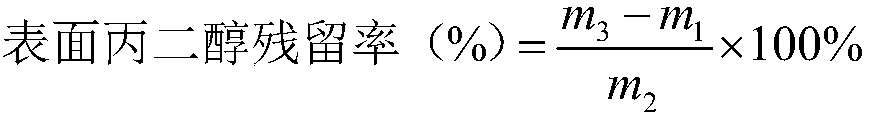

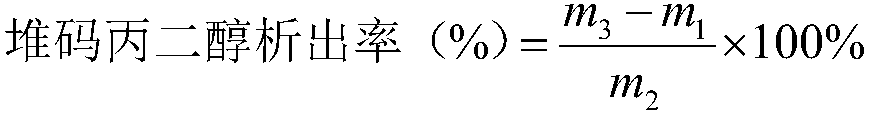

Image

Examples

Embodiment 1

[0104] After drying 20kg of bagasse in a hot air oven, pulverize it through a pulverizer to obtain bagasse powder with a moisture content of 8wt% and a particle size of 20 meshes; pulverize 80kg of beet pulp particles through a pulverizer to obtain a moisture content of 12wt%. , particle size is 50 purpose beet meal powder; bagasse powder and sugar beet meal powder are placed in the mixer and mixed, and the mixing time is 1min to obtain composite carrier powder; 67kg propylene glycol is evenly sprayed on the obtained composite carrier In the powder, use a feed mixer to stir the mixture of propylene glycol and the obtained composite carrier powder at room temperature at a speed of 28 rpm for 15 minutes, and seal and store the mixture of propylene glycol and carrier after mixing evenly. for 24 hours, so that the propylene glycol is completely absorbed by the feed carrier, and then the sealed and stored mixture is stirred at a speed of 32rpm for 3 minutes, so as to break all the l...

Embodiment 2

[0108] After drying 50kg of bagasse with a drum, it is crushed by a kneading cutter to obtain bagasse powder with a moisture content of 5wt% and a particle size of 50 meshes; 100kg of beet pulp particles are crushed by a pulverizer to obtain a moisture content of 11wt%. , particle size is 80 purpose beet meal powder; bagasse powder and sugar beet meal powder are placed in the mixer and mixed, and the mixing time is 2min to obtain composite carrier powder; 180kg propylene glycol is evenly sprayed on the obtained composite carrier In the powder, use a feed mixer to stir the mixture of propylene glycol and the obtained composite carrier powder at room temperature at a speed of 28rpm, and the stirring time is 25min. The mixture of propylene glycol and carrier after mixing is sealed and preserved. For 48 hours, so that the propylene glycol is completely absorbed by the feed carrier, and then the sealed and stored mixture is stirred at a speed of 28rpm for 3 minutes, so as to break a...

Embodiment 3

[0112] After drying 10kg of bagasse in a fluidized bed, pulverize it through a pulverizer to obtain bagasse powder with a moisture content of 10wt% and a particle size of 10 meshes; pulverize 90kg of sugarcane meal particles through a pulverizer to obtain a moisture content of 14wt% %, a particle size of 20 mesh sugar beet meal powder; bagasse powder and sugar beet meal powder are placed in a mixer for mixing, and the mixing time is 2min to obtain a compound carrier powder; 67kg of propylene glycol is evenly sprayed on the obtained compound carrier powder In the carrier powder, use a feed mixer to stir the mixture of propylene glycol and the obtained composite carrier powder at room temperature at a speed of 32 rpm for 15 minutes, and seal the mixture of propylene glycol and carrier after mixing uniformly. The time is 6 hours, so that the propylene glycol is completely absorbed by the feed carrier, and then the sealed and stored mixture is stirred at a speed of 28 rpm for 5 min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com