Quizalofop-p-ethyl microcapsule suspension agent prepared by using porous starch as carrier, and preparation method of quizalofop-p-ethyl microcapsule suspension agent

A technology of microcapsule suspending agent and porous starch, which is applied in the fields of botanical equipment and methods, biocides, biocides, etc., can solve the problems of complex manufacturing methods and technological processes, irregular morphology of microcapsules, easy agglomeration, etc. To achieve the effect of being beneficial to life and health, the preparation method is simple and reliable, and it is not easy to burn and explode.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

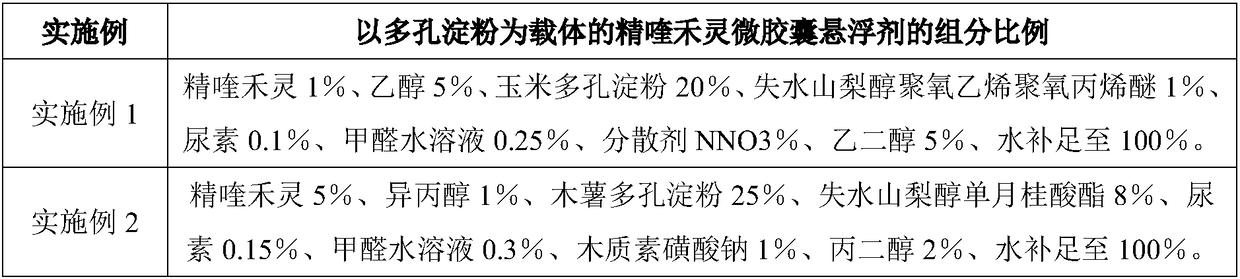

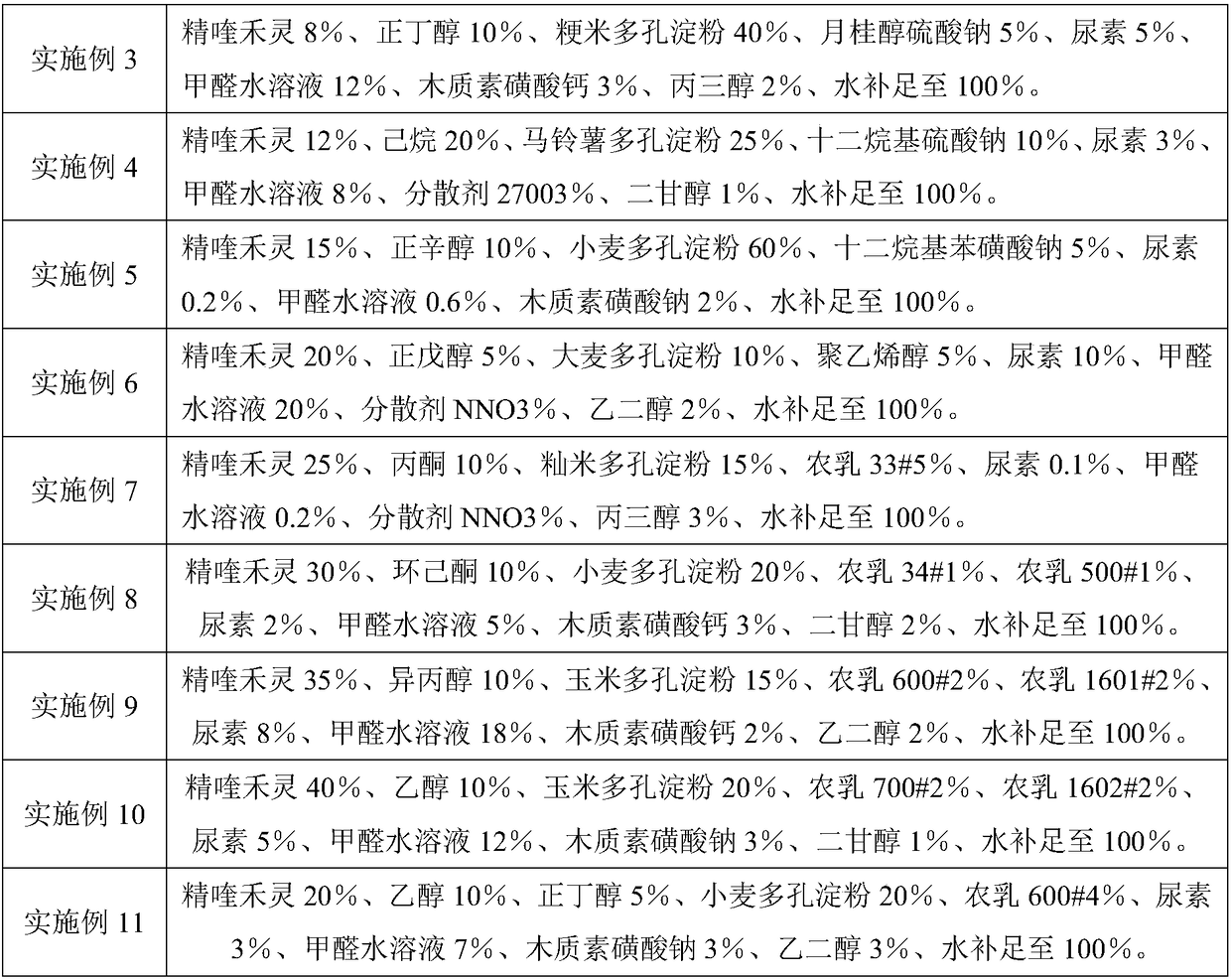

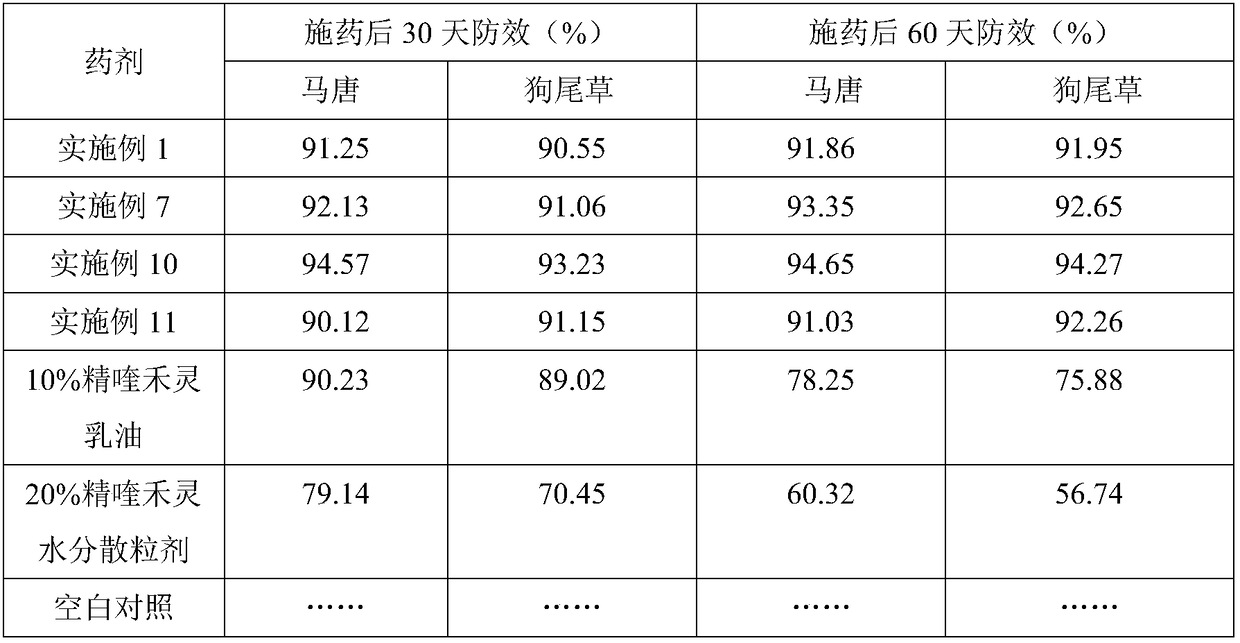

Examples

Embodiment 1

[0030] Example 12. To prepare the quizalofop-p-p-ethyl microcapsule suspension of 1% with the porous starch as the carrier by the mass percentage composition described in Example 1, its concrete steps include as follows:

[0031] Step 1: Add 1 kg of quizalofop-p-ethyl to 5 kg of ethanol, then add 20 kg of corn porous starch and 1 kg of sorbitan polyoxyethylene polyoxypropylene ether, and stir for 1 hour to obtain a stable adsorption The homogeneous emulsion A;

[0032] Step 2: Mix 0.1 kg of urea with 0.25 kg of formaldehyde solution with a mass percentage of 37%, add dropwise a 5% sodium hydroxide aqueous solution and adjust the pH to 8, and then heat to 60°C , stirring and reacting for 1.5h to obtain urea-formaldehyde resin prepolymer B;

[0033] Step 3: The prepared urea-formaldehyde resin prepolymer B and the emulsion A are fully stirred and mixed at room temperature to form a mixed solution, and a 5% hydrochloric acid aqueous solution is added dropwise to adjust the pH o...

Embodiment 13

[0035] Example 13. To prepare the quizalofop-p-p-ethyl microcapsule suspension of 25% with porous starch as the carrier by the mass percentage composition described in Example 7, its specific steps include as follows:

[0036] Step 1: Add 25 kg of quizalofop-p-ethyl to 10 kg of acetone, then add 15 kg of indica rice porous starch and 5 kg of Nongru 33#, and stir thoroughly for 1 hour to obtain a uniform emulsion A with stable adsorption;

[0037] Step 2: Mix 0.1 kg of urea with 0.2 kg of formaldehyde solution with a mass percentage of 37%, add dropwise a 5% sodium hydroxide aqueous solution and adjust the pH to 8, and then heat to 60°C , stirring and reacting for 1.5h to obtain urea-formaldehyde resin prepolymer B;

[0038] Step 3: The prepared urea-formaldehyde resin prepolymer B and the emulsion A are fully stirred and mixed at room temperature to form a mixed solution, and a 5% hydrochloric acid aqueous solution is added dropwise to adjust the pH of the mixed solution to 5...

Embodiment 14

[0040] Example 14. To prepare the quizalofop-p-p-ethyl microcapsule suspension of 40% with porous starch as the carrier by the mass percentage composition described in Example 10, its specific steps include as follows:

[0041] Step 1: Add 40 kg of quizalofop-p-ethyl to 10 kg of ethanol, then add 20 kg of corn porous starch, 2 kg of Nongru 700#, and 2 kg of Nongru 1602#, and fully stir for 1 hour to obtain stable adsorption Uniform emulsion A;

[0042]Step 2: Mix 5 kg of urea with 12 kg of formaldehyde solution with a mass percentage of 37%, and add dropwise a 5% sodium hydroxide aqueous solution with mass percentage to adjust the pH to 8, and then heat to 60° C. , stirring and reacting for 1.5h to obtain urea-formaldehyde resin prepolymer B;

[0043] Step 3: The prepared urea-formaldehyde resin prepolymer B and the emulsion A are fully stirred and mixed at room temperature to form a mixed solution, and a 5% hydrochloric acid aqueous solution is added dropwise to adjust the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com