Corrosive for displaying sintering ferrite microstructure and application of corrosive

A technology of microstructure and corrosive agent, which is applied in the field of ferrite microstructure observation, can solve the problems of great threat to operators' health, high toxicity and high volatility of hydrofluoric acid, etc., and achieves convenient and fast preparation process and simple raw materials. Easy to obtain, high practical value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

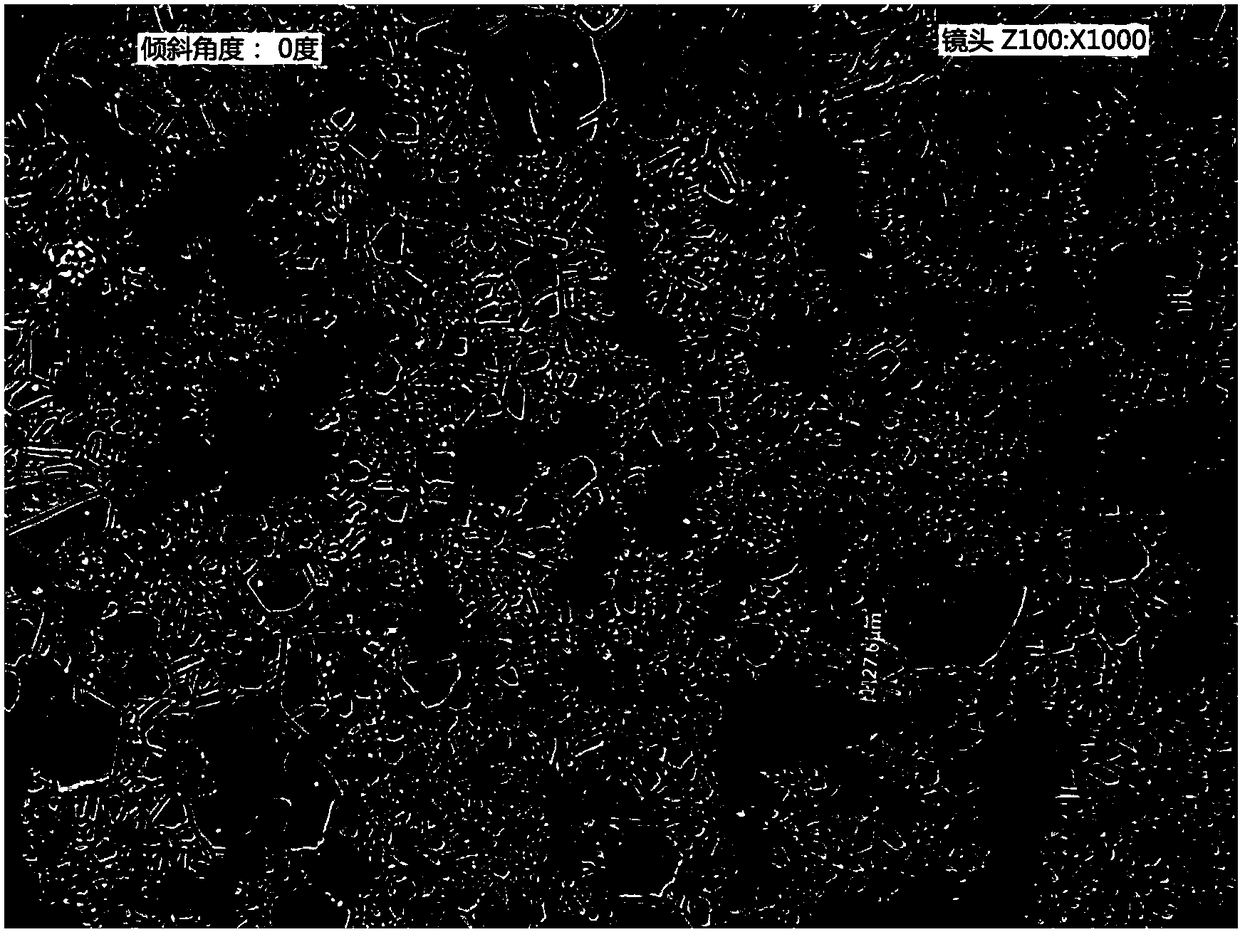

[0028] A corrosion agent showing the microstructure of sintered ferrite, which comprises hydrochloric acid, stannous chloride and deionized water with a concentration of 37% (mass fraction), and the hydrochloric acid and deionized water are configured according to the volume ratio of 1:1 Configure, the final concentration of hydrochloric acid in the etchant is 18% (mass fraction), the final concentration of stannous chloride in the etchant is 10% (mass fraction), stir evenly, and corrode the sample at room temperature. Immerse the sintered ferrite sample after mechanical grinding and mechanical polishing in the etchant for 10 minutes. After the surface of the sample becomes gray and dark, wash it with water and then with absolute ethanol. After drying with a hair dryer, observe it with a metallographic microscope , so as to get figure 1 The metallographic photograph shown; by figure 1 It can be seen that the microstructure of the sintered ferrite sample is clear and easy to m...

Embodiment 2

[0030] A corrosion agent showing the microstructure of sintered ferrite, which comprises the configuration of hydrochloric acid, stannous chloride and deionized water with a concentration of 30% (mass fraction), and the hydrochloric acid and deionized water are in a volume ratio of 1:1 For configuration, the final concentration of hydrochloric acid in the etchant is 15% (mass fraction), the final concentration of stannous chloride in the etchant is 10% (mass fraction), stir evenly, and corrode the sample at room temperature. Immerse the sintered ferrite sample after mechanical grinding and mechanical polishing in the etchant for 20 minutes. After the surface of the sample becomes gray and dark, wash it with water and then with absolute ethanol. After drying with a hair dryer, observe it with a metallographic microscope , so as to get figure 2 The metallographic photograph shown; by figure 2 It can be seen that the microstructure of the sintered ferrite sample is clear and e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com