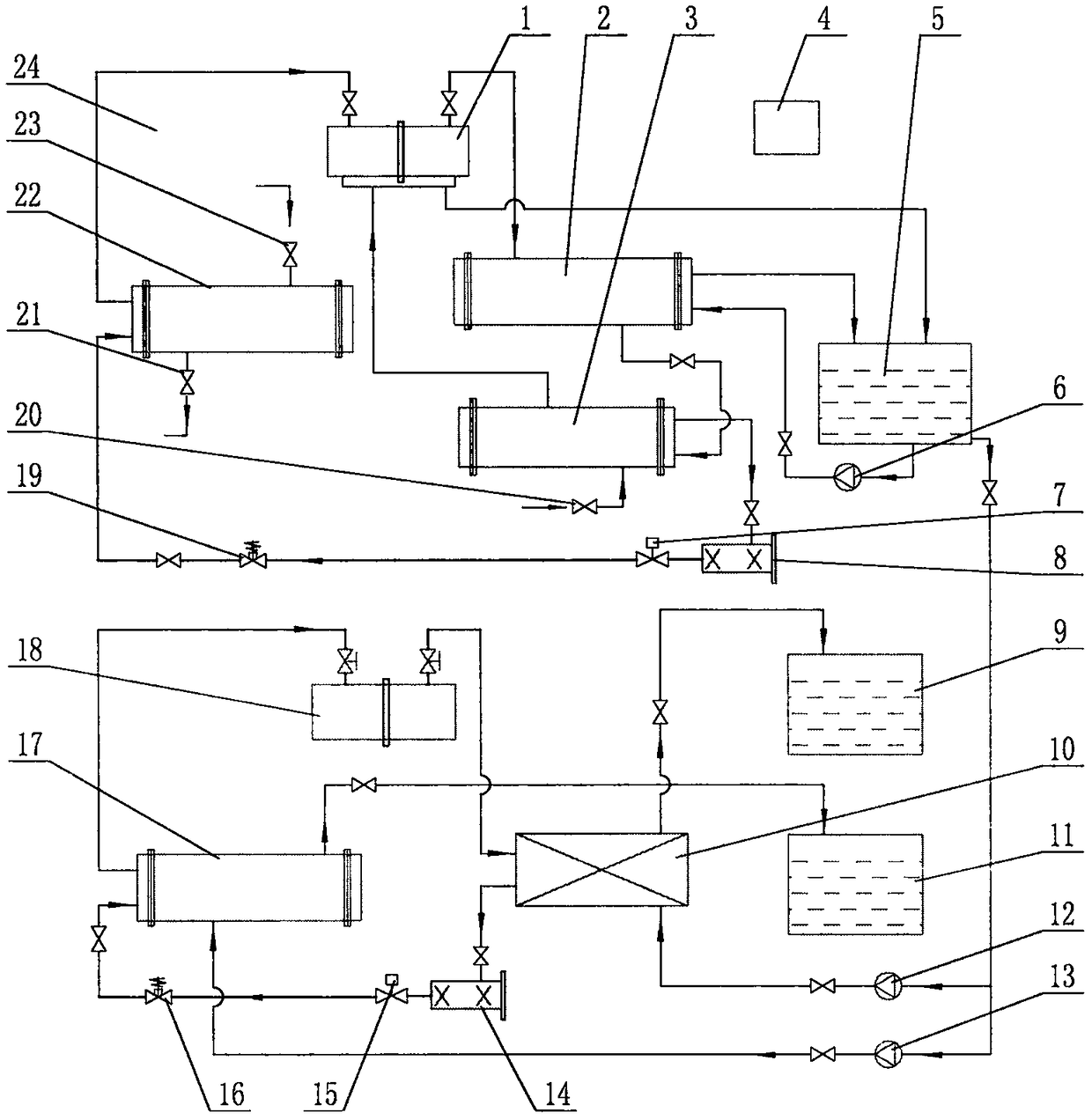

The working medium at the outlet of the horizontal condenser (2) enters the supercooler (3) for

supercooling and exothermic heat, and the working medium at the outlet of the subcooler (3) enters the primary

drying filter (8) for drying and purification, and the primary drying filter (8) The outlet

working fluid enters the evaporative condenser (22) through the first-stage restrictor (7) and the first-stage expansion valve (9) to evaporate and absorb heat, and the outlet

working fluid of the evaporative condenser (22) enters the screw compressor (1 ) to carry out a compression cycle, and the primary

working fluid forms the internal circulation heating of the system; when the primary water system is working, the system supply water enters the water side of the subcooler (3) from the supplementary water inlet control valve (20) to preheat and supercool The outlet on the water side of the compressor (3) enters the water side of the screw compressor (1) for heat absorption, the outlet on the water side of the screw compressor (1) enters the buffer of the heat preservation heat

storage tank (5), and the outlet of the heat preservation heat

storage tank (5) enters the hot water pump (6) Boost the pressure, hot water from the outlet of the hot water pump (6) enters the water side of the horizontal condenser (2) for heat absorption, and the hot water from the outlet of the horizontal condenser (2) enters the buffer of the heat preservation accumulator (5); Unit 1 The first-stage system and the refrigeration system are interlocked to automatically control the start-up and shutdown work. When the refrigeration system starts or stops, the first-stage system automatically starts or stops, and the waste

heat carrier working fluid from the refrigeration system enters the

evaporation and condensation through the refrigeration waste heat inlet control valve (23). The device (22) releases heat, and the carrier working fluid after heat release is returned to the refrigeration system to circulate through the cooling liquid supply outlet control valve (21); the primary system and the secondary system can work at the same time or at different times. When the high-level system is working, it is to provide the required qualified

thermal energy for the slaughterhouse, that is, the semi-hermetic

piston machine (18) outlet working fluid enters the sleeve condenser (10) for condensation and heat release, and the sleeve condenser (10) outlet working fluid Enter the secondary dry filter (14) for drying and purification, the outlet working medium of the secondary dry filter (14) enters the dry

evaporator (17) through the secondary

throttle (15) and the secondary expansion valve (16) Evaporating and absorbing heat, the working medium at the outlet of the dry

evaporator (17) enters the semi-closed

piston machine (18) for a compression cycle, which goes round and round, and the working medium of the secondary system forms the internal circulation heating of the system; the secondary hot water system is formed by heat preservation and heat storage The hot water at the outlet of the tank (5) enters the condenser hot water pump (12) and the evaporative hot water pump (13) respectively for pressurization, and the hot water at the outlet of the condensing hot water pump (12) enters the water side of the casing condenser (10) to absorb heat. The high-temperature hot water at the outlet of the tube condenser (10) enters the buffer of the hot

water pool (9) for slaughtering

livestock and poultry

scalding, and provides a high-temperature hot

water source for the livestock and poultry

scalding workshop, and the hot water at the outlet of the evaporating

heat pump (13) enters the dry evaporator (17 ) part of the heat is released on the water side, and the hot water at the outlet of the dry evaporator (17) enters the buffer of the slaughtering livestock and poultry cleaning hot

water pool (11), providing a cleaning hot

water source for the livestock and poultry cleaning workshop; this technology solves the problem of slaughtering industry and

food processing industry. At the same time, it solves the problem of atmospheric environmental

pollution, the problem of large

capital investment in "

coal to

electricity" or "

coal to gas", and the problem of energy saving and consumption reduction of enterprises, which is beneficial to the

sustainable development of the economy

Login to View More

Login to View More  Login to View More

Login to View More