Two-section type rubber film sealing gas cabinet reconstructed from regularly polygonal diluted oil sealing gas cabinet

A regular polygon, two-stage technology, applied in the field of two-stage rubber membrane sealed gas cabinets, can solve the problems of not meeting the needs of single-stage cabinet transformation, unable to connect to the grid, and insufficient installation accuracy. Dead space, the effect of increasing utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

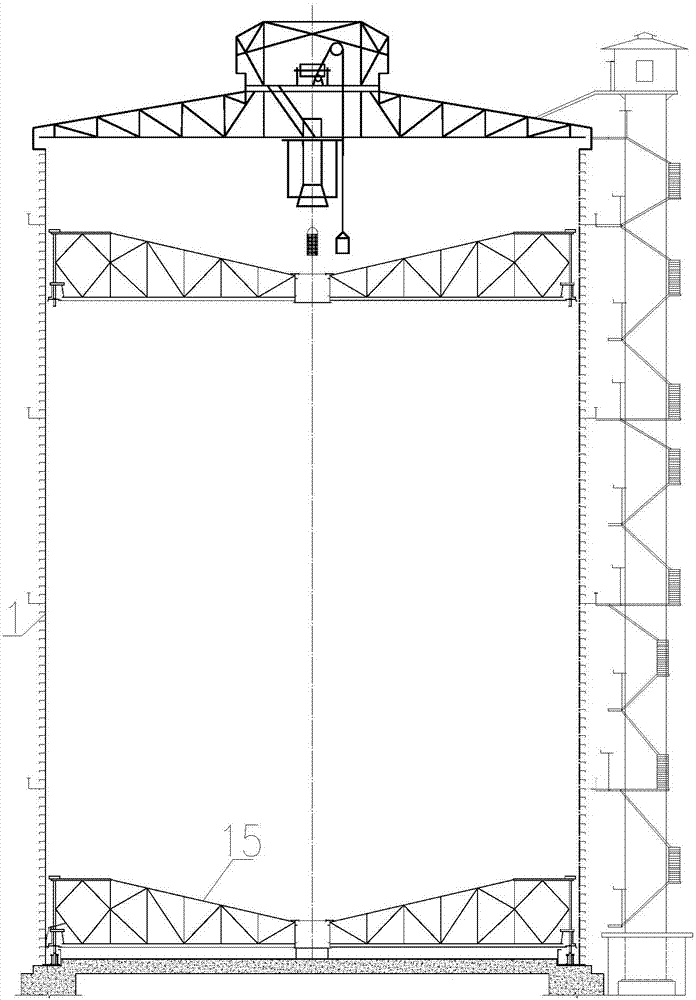

[0036] figure 1 Shown is the general assembly drawing of the original regular polygonal thin oil-sealed gas cabinet. The regular polygonal thin oil-sealed gas cabinet includes a regular polygonal cabinet body 1 and the original piston device 15. The operating state of the regular polygonal thin oil-sealed gas cabinet is It is greatly affected by the precision control during construction and the maintenance status during the operation stage. Especially if the precision during construction is not enough, the sealing effect of the gas cabinet after it is put into production is difficult to meet the index requirements, and problems such as oil leakage and frequent start-up of the oil pump often occur.

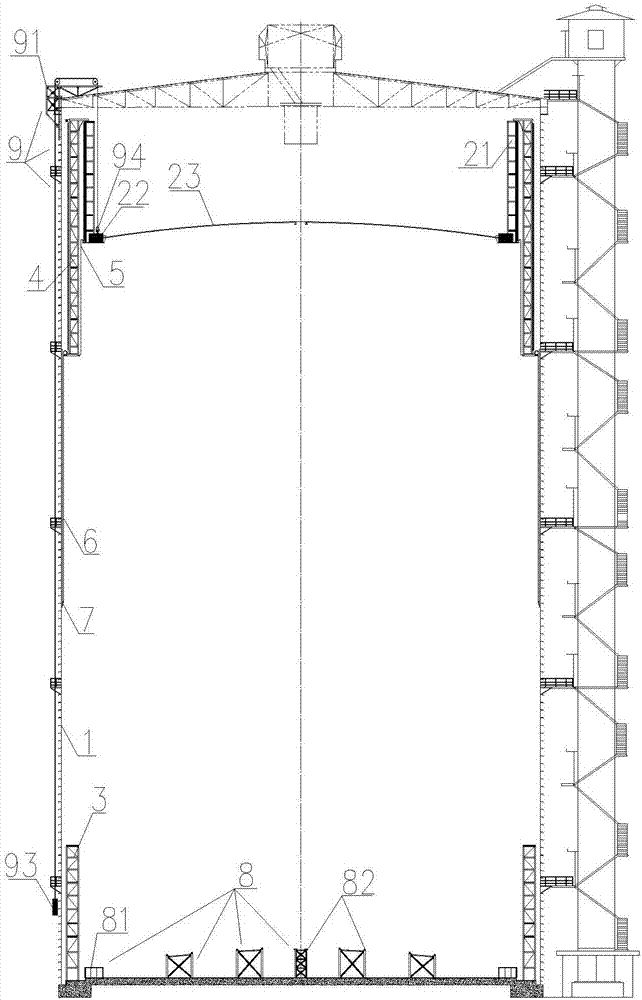

[0037] Such as Figure 2 to Figure 4As shown, the two-stage rubber membrane airtight gas cabinet reconstructed from the regular polygonal thin oil-sealed gas cabinet of the present invention includes a regular polygonal cabinet body 1, a two-stage gas cabinet piston device 2, a T b...

Embodiment 2

[0050] On the basis of the above-described embodiments, a leveling device 9 is also included, and the leveling device 9 includes a leveling bracket 91, a leveling wire rope 92, a leveling weight 93 and a leveling suspension point 94; the leveling bracket 91 sets At the eaves of the regular polygonal cabinet 1 cabinet top; the leveling suspension point 94 is arranged on the piston ring beam 22; The pulley is also connected with the described leveling weight 93 outside the regular polygon cabinet body 1.

[0051] During reconstruction, the embedded part of the leveling lifting point 94 in the leveling device is pre-embedded when constructing the reinforced concrete of the piston ring beam 22; One end of the leveling support 91 is bypassed and installed on the leveling suspension point 94, and the other end is connected with the leveling weight 93.

[0052] The leveling device 9 in this embodiment is used for leveling the piston device 2 of the two-stage gas cabinet, and adjusti...

Embodiment 3

[0054] On the basis of the above-mentioned embodiments, the outer side of the regular polygonal cabinet 1 is fixedly provided with a release pipe 12, and the top of the release pipe 12 is higher than the cornice of the cabinet body of the regular polygonal cabinet 1 and is provided with a gas release valve 14; 12 The top of the regular polygonal cabinet body 1 is not less than 4m above the cornice of the cabinet body; the top of the regular polygonal cabinet body 1 is installed with a release pipe top opening device 11, and the release pipe top opening device 11 releases the gas through a pulley block and a steel wire rope. The valve 14 is connected; the release pipe push-off device 11 also includes a push rod 13 arranged on the top of the T baffle plate 4 .

[0055] During rebuilding, after the installation of the leveling device 9 is completed, the processed release pipe 12 is installed in place, the top opening device 11 is installed on the top of the cabinet, and the push r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com