Thermal-bridge-free aerated concrete wallboard

A kind of technology of air-entrained concrete and concrete, which is applied in the direction of building components, buildings, building structures, etc., can solve the problems of increasing construction strength and cost, increasing the amount of concrete, and insufficient ductility of shear walls, so as to reduce the dead weight of wall panels, Improve the effect of heat preservation and improve the ability to work together

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

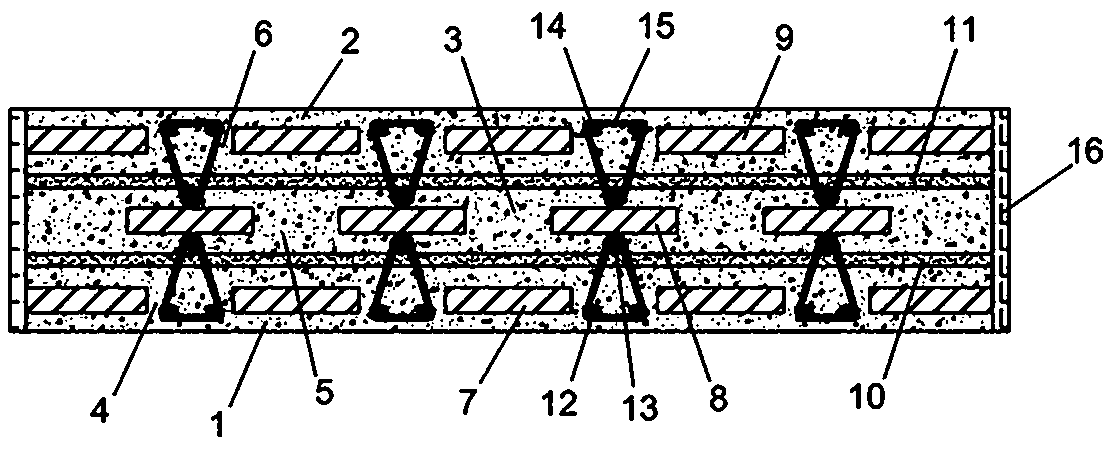

[0021] Such as Figure 1~Figure 2As shown, in a structure of aerated concrete wall panels without thermal bridges, the wall panel structure is symmetrical, and side panels (16) are arranged on both sides. The wall panel structure is divided into inner concrete layer (1), inner concrete layer (1), The first anti-friction layer (10), the concrete interlayer (3), the second anti-friction layer (11) and the outer concrete layer (2); the inner row of hidden columns (4), the outer row of hidden columns (6) and the middle The rows of hidden columns (5) are arranged evenly and alternately with each other, and the first anti-friction layer (10) is arranged between the inner row of hidden columns (4) and the middle row of hidden columns (5), and the middle row of hidden columns (5) and the outer row The second anti-friction layer (11) is arranged between the dark columns (6); the inner row of dark columns (4) is provided with an inner row of heat preservation layers (7), and the middle ...

Embodiment 2

[0023] Such as Figure 1~Figure 2 As shown, in a structure of aerated concrete wall panels without thermal bridges, the wall panel structure is symmetrical, and side panels (16) are arranged on both sides. The wall panel structure is divided into inner concrete layer (1), inner concrete layer (1), The first anti-friction layer (10), the concrete interlayer (3), the second anti-friction layer (11) and the outer concrete layer (2); the inner row of hidden columns (4), the outer row of hidden columns (6) and the middle The rows of hidden columns (5) are arranged evenly and alternately with each other, and the first anti-friction layer (10) is arranged between the inner row of hidden columns (4) and the middle row of hidden columns (5), and the middle row of hidden columns (5) and the outer row The second anti-friction layer (11) is arranged between the dark columns (6); the inner row of dark columns (4) is provided with an inner row of heat preservation layers (7), and the middle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com